The next thing that I would like to discuss is the operation of the circuit as a unit. The CIRCUIT is the common name obtained from the path that the ore takes as it progresses through any particular process. In this case grinding. I won’t deal with start-up procedure as it will change from mine to mine depending on the equipment each has and the different safety checks required.

The only thing that I would like to mention about start up is, that it is common practice to start the last piece of equipment first and proceed to the first piece of equipment last. After your support systems have been turned on, air blowers, oil pumps, cooling water, stop for a moment review each piece of equipment in your mind. Mentally VERIFYING that every function that is needed has been turned on. Once you are satisfied that the mill is ready to run and you have obtained the go ahead from your supervisor, start up the last piece of machinery that is still your responsibility.

After it has been started, work backwards through the grinding circuit until the last feed belt has been turned on. If you started the first piece of equipment first by the time you got to your second piece of equipment you would have ore all over the place. When you shut the circuit down you go the opposite way, you shut the feed belts off first. Then, as you come to the next piece of equipment you allow it time to empty itself before shutting it down. This is called GRIND OUT TIME and the management will set the time allowed for each piece of equipment.

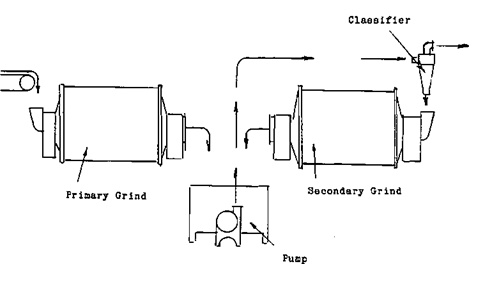

As I said this varies from mine to mine so I won’t spend too much time on it, what I. would like to discuss is the effect that each individual piece of equipment will have on the operation of the circuit.The most common circuit design that you will find in mining is represented “by the third schematic that we presented earlier. In this flow sheet there is a Rod mill, Pump, Classifier, and Ball mill. The ore travels through the Rod mill and is pumped to the classifier. This is the heart of the grinding circuit. The entire milling process is controlled “by using this piece of equipment’s product as a guide. There are three different types of Classifiers, SPIRAL, RAKE and HYDROCYCLONE, again we will use the most common, the hydrocyclone, or as it is normally referred to, the cyclone.