In model 1 with Stephen, and in the previous topic, we saw that the geological aspect is one of the main factors that affect the design of a surface mine. What are the characteristics and other aspects should be taken into a code for the final configuration of the surface mine. Between them, we have to take into account of the safety, economics, and the recovery of the material.

In model 1 with Stephen, and in the previous topic, we saw that the geological aspect is one of the main factors that affect the design of a surface mine. What are the characteristics and other aspects should be taken into a code for the final configuration of the surface mine. Between them, we have to take into account of the safety, economics, and the recovery of the material.

In the next topics we will see how all this could be achieved. But before that, let’s have I look at which are the main physical elements that make up a surface mine. When we create an excavation with the purpose to mining a deposit, the excavation is called, pit. The pit is a hole in the ground with sloping sides leading to the pit floor. The waste from the hole in the ground is placed on a dump. In a later stage, we will discuss what is a dump and we will have a look at some images that clearly show which has typical characteristics of a dump site.

Surface mines are constructed in very different sizes and shapes. Surface mine is in continuous evolution, especially in relation to the extent of the deposit. The way in which a surface mine involves and expands depends on several factors that include, the geological and the deposit characteristics, the surface constraints, the project and operational constraints. In module one, with Stephen, we saw that coal deposits occur in stratiform shapes. And several mineral deposits occur in pipe shaved or loads. Stratiform deposits, Such as coal, are often mined using opencast configurations. In these images taken from Sydney basin in Australia, we can see that opencast pits can occupy extremely large areas. Disseminated deposits, pipe deposits or loads, are often mined in deep pits which usually have conical forms. The pits are exposed to the atmosphere. And in this case, we talk about open pits.

These images are from the largest open pit gold mine in Australia. The Fimiston Open Pit, known as the super pit, located in Kalgoorlie in Western Australia. The Pit stretches 3.8 kilometers by 1.35 kilometers wide at the surface. And it goes down to a depth of 500 meters.

Another example of very large open pit is given by these images taken from the Highland Valley copper mine in central British Columbia in Canada. In model 1, we learn that the metalliferous surface mine, the slopes are referred as hanging wall and foot wall.

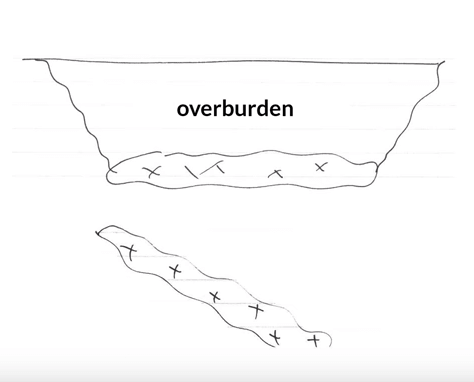

The hanging wall is the underside of the wall rock overlying an ore body. And the footwall is the top of the rock that underlies the ore body. The hanging wall must be removed to expose the body. Hence, the hanging wall rock becomes hanging wall waste, once the inclined ore party is removed, it exposes the footwall, which is the rock below the ore body. If you are in the mining operation, some of the footwall is also removed. Then the waste produced is called footwall waste. If the deposit is flat or is dipping and not outcropping to the surface that is located a certain shallow depth from it, then the overburden becomes waste rock in the surface mining process. When we mine a deposit, it becomes easy to think that it’s not practical to excavate or to work with machinery and equipment on sloping surfaces.

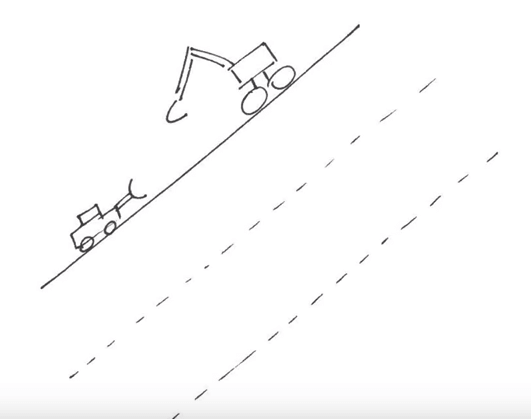

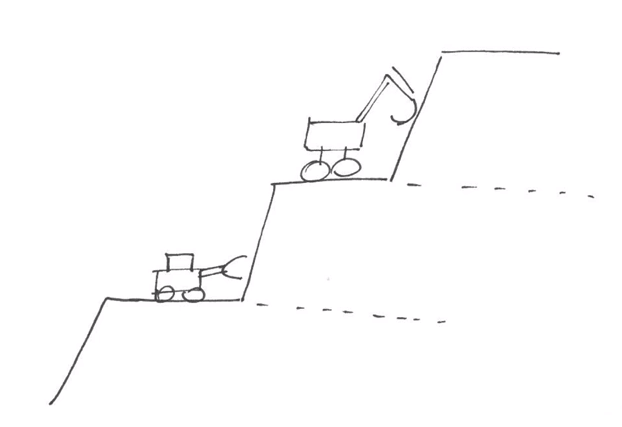

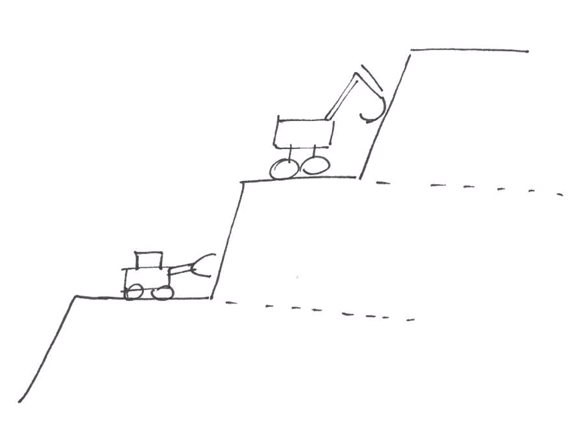

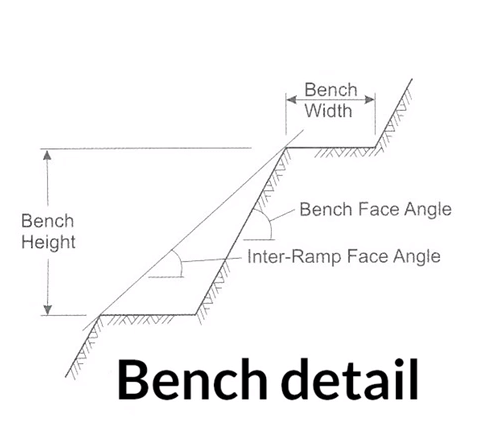

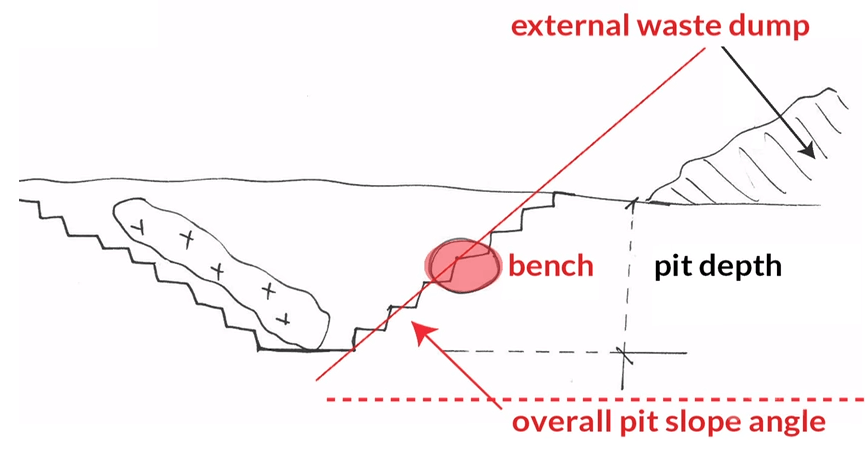

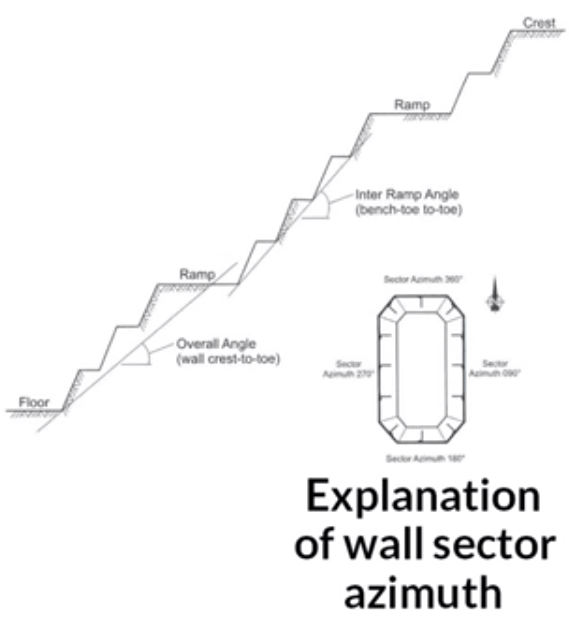

Let’s imagine for a second to have to work with equipment and machinery on a slope like this. It is easy to think that this is not very practical for both machinery and personnel. Instead, it is much more practical to consider flat working surfaces. This is why pit slopes are created by removing the waste rock in a series of convenient bites, which excavate the rock in horizontal slices of limited height. This leads to the formation of benches that are short, inclined slope come on separated by horizontal steps. The pit depth is the total depth of the pit from the lowest point on the floor to the top of the top bench. The waste material is removed from the pit and stored in an external waste dump. The amount of waste rock depends on your choice of the overall pit slope angle that we can define as the angle formed joining the top of the lowest bench to the crest of the top bench. In order to have a safe, functional, and economic slope design, three main aspects should be taken into account – the overall slope angle, the conflagration of benches, the ramps and inter-ramps configuration or inter-ramp angle. As we said before, the mining process works by the excavation of small bites that will define benches. The benches should have a face angle that allows to achieve a stable face and the stable crest, a sufficient width to mitigate the danger of rock fall from slope above, and to provide access for working personnel and equipment, and a maximum height not exceeding the capabilities of the loading and excavation equipment. Ramps are continuous roads allowing vehicle access to the pit. They may spiral around the pit or be located on just one side of the pit with switchbacks at each end. Ramps should accommodate two-way traffic with grades limited to allow for a full truck to climb out of the pit. In order to have a good design, the number of tight curves and turns should be minimized. In general, ramps are sloping. Instead benches are flat and horizontal. Ramps are also much wider than benches in order to accommodate the traffic of the trucks that are transporting the materials. The succession of benches between two access ramps is defined as inter-ramp slope.

In this image from Kennecott Utah copper mine in Salt Lake Valley, we can clearly identify benches and ramps. The mine is the largest man-made excavation on earth. In this case, ramp spiral around the pit. As you can see in this sketch is the overall configuration of benches, ramps, and inter-ramp slopes, which ultimately determine the overall pit angle.

https://youtu.be/pW1cxv0YP-Y

The next topic, we will see which are the main processes and the models that should be taken into account in order to have a stable slope design.