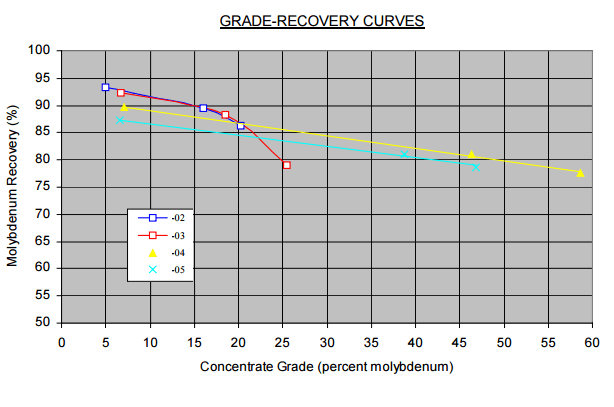

A Molybdenum Flotation case study with about 6% of the molybdenum contained in the feed is present as an oxide form and about 90% of this is not recovered to the flotation concentrate. Recovery of molybdenum into the rougher concentrate varied between 90 to 95% at a concentrate grade of 2.5 to 3.7% molybdenum. The rougher concentrate can be upgraded to a marketable grade molybdenum concentrate at between 77 to 80% overall molybdenum recovery. Regrinding of the rougher concentrate is required in order to achieve target final concentrate grade. The sample tested was a bulk grab sample and as such is unlikely to be a true representation of the resource.

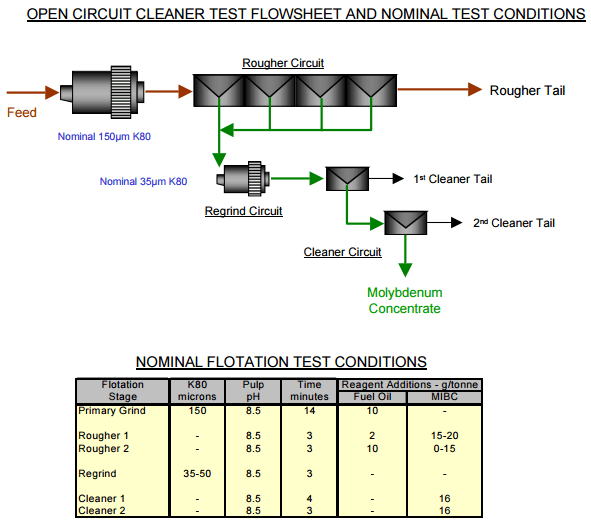

This Molybdenum Flotation metallurgical program consisted of performing one rougher and four batch cleaner flotation tests on the sample of sulphide ore. The nominal primary grind P80 selected for this series of tests was 150µm. The cleaner tests were designed to investigate the effect of a regrind stage between rougher and cleaner flotation. Here above you see the laboratory flowsheet, test conditions and the grade-recovery curves for the four cleaner tests. In considering the results achieved in the single rougher test and the data presented, the following points of interest are noted:

The feed and test products for test 1 were assayed for molybdenum oxide and approximately 6% of the molybdenum in the feed was present as molybdenum oxide. The metallurgical balance for test 1 indicates that 91.4% of the oxide was lost to the final tailing. – Tests 2 and 3, which did not have a regrind stage between the rougher and cleaner circuit, did not produce a marketable grade concentrate. The final concentrate grade in these tests averaged about 22% by weight molybdenum at 85% recovery of molybdenum into the final concentrate. – Tests 4 and 5, which included a regrind stage between the rougher and cleaner circuit, did produce an acceptable final concentrate product. The average results from these tests suggest that the mineralized sample can be upgraded to produce a concentrate containing about 50% molybdenum by weight. At this grade, recovery of molybdenum was determined to range between 77 to 80%.

There may be some opportunity to improve upon the current results as the tests are not optimised and there is a need to define the optimal primary and regrind sizes.