Table of Contents

- Features and Benefits

- Grinding jars for Static Mixing Applications

- Stainless steel Micro vials

- Fast clamping jars for

- Micro vial holder for cell disruption

- Ice bath for cryogenic grinding

- Micro Ball Mill

- Operator Convenience & Safety

- When to use a high energy ball mill

- Micro Ball Mill

- Grinding and Mixing examples

- Cryogenic Ball Milling

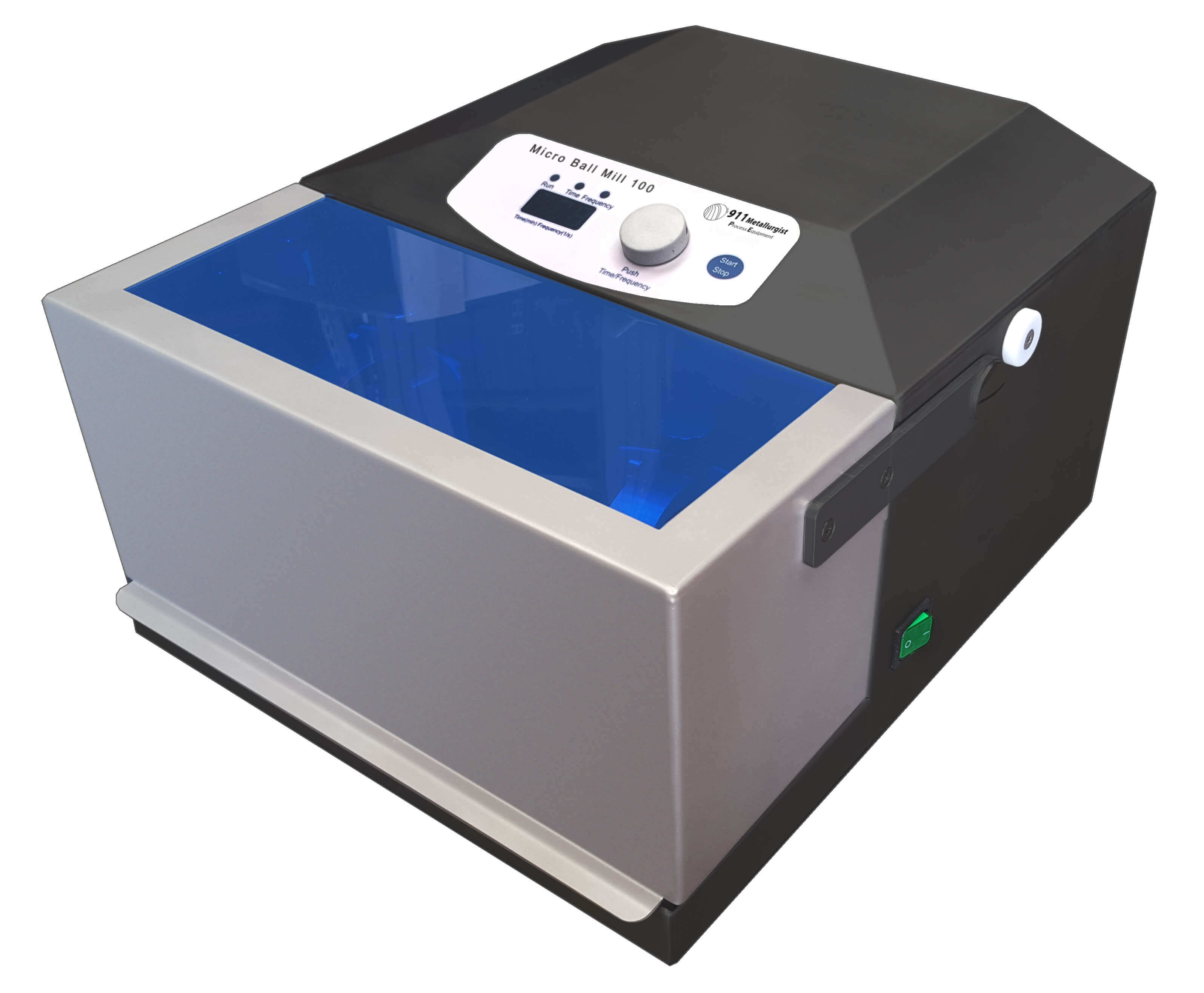

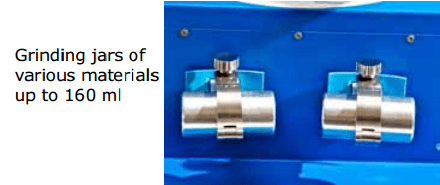

A Superior Mixer Mill engineered for rapid and reproducible sample preparation procedures. This High Energy Ball Mill can handle simultaneously two or more samples from 0.2 ml up to 160 ml. Grinding, Mixing and Cell disruption in on machine. This MIXER MILL is designed for “1001 laboratory applications”. Typically Processing times are between 15 and 45 seconds. This HIGH ENERGY BALL MILL can prepare 2 or more samples from 0.2ml up to 160ml. It is designed as well for high-sample throughput.

All Static Mixers, have some helical mixing element which directs the flow of material radial toward the pipe walls and back to the centre. Additional velocity reversal and flow division results from combining alternating right- and left-hand elements, thus increasing mixing efficiency. All material is continuously and completely mixed, eliminating radial gradients in temperature, velocity and material composition.

Features

- Universal and highly efficient, blending and disruption

- Large range of grinding jars and accessories

- Large range of grinding balls and accessories

- Extremely short processing times

- Designed for high sample throughput

- Reproducible results by digital pre-setting of all working parameters

Features and Benefits

Features and Benefits

- Universal and highly efficient grinding, blending and disruption

- Large range of grinding jars and accessories

- Extremely short processing times

- Designed for high sample throughput

- Reproducible results by digital pre-setting of all working parameters

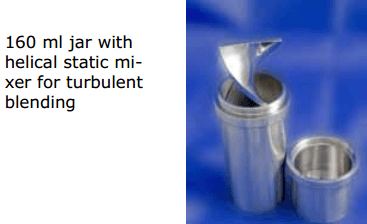

Grinding jars for Static Mixing Applications

- Turbulent Blending

- Laminar Blending

- Liquid Dispersion

- Gas-Liquid Dispersion

All LAB WIZZ Static Mixers, have some helical mixing element that directs the flow of material radial toward the pipe walls and back to the center.  Additional velocity reversal and flow division result from combining alternating right- and left-hand elements, thus increasing mixing efficiency. All material is continuously and completely mixed, eliminating radial gradients in temperature, velocity, and material composition.

Additional velocity reversal and flow division result from combining alternating right- and left-hand elements, thus increasing mixing efficiency. All material is continuously and completely mixed, eliminating radial gradients in temperature, velocity, and material composition.

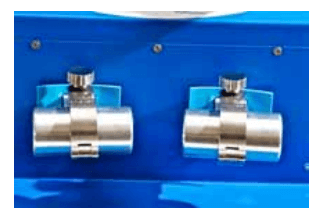

Stainless steel Micro vials

Stainless steel Micro vials

Stainless steel Micro vials are used for cryogenic grinding of small sample amounts or for standard grinding applications of small samples such as soil or grain using a steel or tungsten carbide bead. Steel vials ensure a much higher heat transformation in order to optimize the heating and cooling. The stainless steel Micro vials are available with a grinding ball pre-filling optional.

Fast clamping jars for

Fast clamping jars for

- Dry grinding

- Wet Grinding

- Ultra Fine Grinding

- Mechanical alloying

Micro vial holder for cell disruption

- Micro vial adapter plate for 10 micro vials

- Micro vial adapter for 4 micro vials

Designed for high analytical screening, the LAB WIZZ efficiently and safely disrupts samples of spores, microorganisms, plant and animal tissue, or soil samples at a time.

The samples along with extraction media and small metallic or ceramic balls are placed in micro vials. After 2 minutes of preparation in the LAB WIZZ more than 95% of the cells are disrupted. Because balls and vials plates are disposable the method is ideal for PCR, PAGE, and Probe applications where cross-contamination between samples cannot be tolerated.

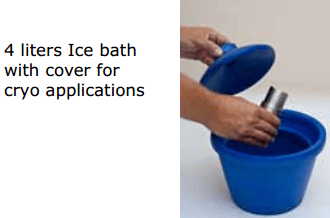

Ice bath for cryogenic grinding

For heat-sensitive materials such as plastics and rubber, it is possible to embrittle the material with liquid nitrogen and perform additional external freezing of the fast clamping jars. Those jars are either made from Teflon or from stainless steel and are suitable for cryogenic grinding applications.

- Insulated Ice bath 4 Liter with Cover

- Tongue for frozen grinding jars

- Safety Glass

Micro Ball Mill

Engineered for rapid sample preparation procedures:

- Dry Grinding / Wet Grinding / Ultra Fine Grinding / Cryogenic Grinding

- Turbulent Blending / Laminar Blending / Liquid-Liquid Dispersion / Gas-Liquid Dispersion

- Mechanical Alloying

- Cell disruption for DNA / RNA extraction

Our Lab mixer mill can handle simultaneously two or more samples from 0.2 ml up to 160 ml.

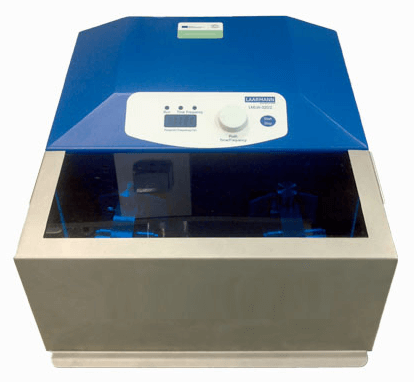

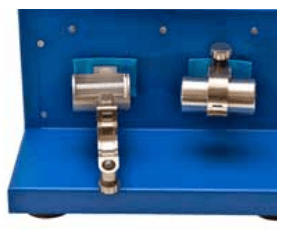

Operator Convenience & Safety

Maximum Grinding performance and maximum safety is important for Mixer Mills. Due to an integrated motor break the machine can only be started when the “Easy Cover” is closed. The unique “Easy Clamp system” allows the simple and safe clamping of all grinding jars up to 160ml.

The grinding chamber, easy clamp system as well as the swinging arm is made from high precision stainless steel to meet all food and pharmaceutical requirements. Due to the new motor concept and a motor drive, this mixer mill is maintenance free.

|

|

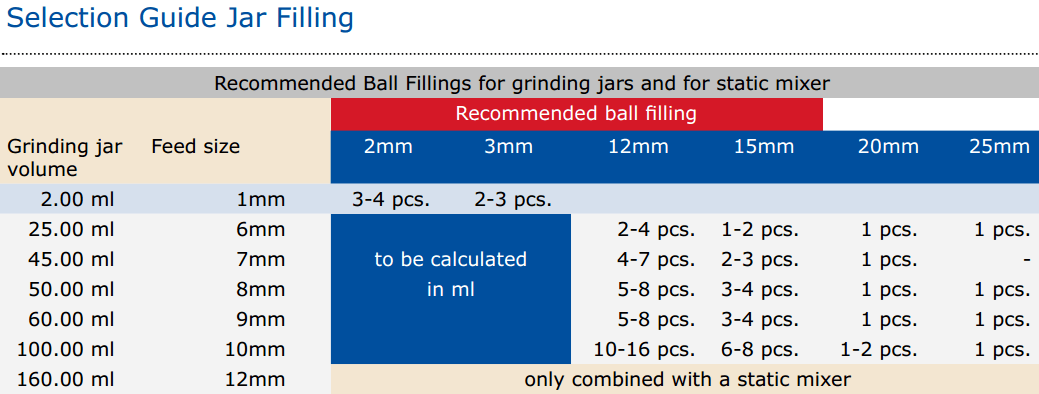

Selection Guide Jar Filling

When to use a high energy ball mill

|

|

|

|

|

|

Micro Ball Mill

Micro Ball Mill

Due to the unique combination of a wide range of grinding jars of various materials the LAB WIZZ is capable to practically meet all demands of today’s laboratory needs.

- Grinding (wet and dry)

- Cell disruption

- Mixing XRF Prep

- Turbulent blending (Static Mixer)

- Cold grinding

Due to the combination of high energy vibration and the punch of the grinding balls the LAB WIZZ cannot only grind hard and brittle materials but as well all medium soft, soft materials and elastic materials.

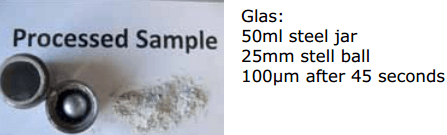

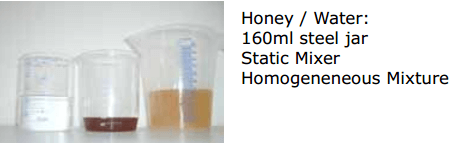

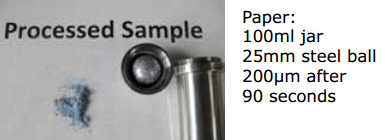

Grinding and Mixing examples

Glass: 50ml steel jar 25mm steel ball 100 µm after 45 seconds Glass: 50ml steel jar 25mm steel ball 100 µm after 45 seconds |

Honey / Water: 160ml steel jar Static Mixer Homogeneous Mixture Honey / Water: 160ml steel jar Static Mixer Homogeneous Mixture |

Paper: 100ml jar 25mm steel ball 200µm after 90 seconds |

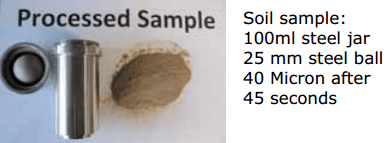

Soil sample: 100ml steel jar 25 mm steel ball 40 Micron after 45 seconds |

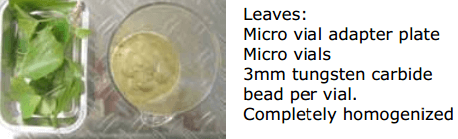

Leaves: Micro vial adapter plate Micro vials 3mm tungsten carbide bead per vial. Leaves: Micro vial adapter plate Micro vials 3mm tungsten carbide bead per vial.Completely homogenized |

Rubber: 50ml steel jar 20 mm steel Ball after cryogenic grinding Rubber: 50ml steel jar 20 mm steel Ball after cryogenic grinding |

Application examples.

Paper, alloys, animal feed, bones,plants, ceramics, cereals, chemical products,coke, drugs, glass, grains, hair, minerals, oil seeds, ores,coal, materials, plastics, sewage sludge, soils, straw, tablets, textiles, tissue, tobacco, waste samples, wood and many more.

35ml:

- Steel

- Stainless steel

- Heavy metal poor steel

- Zirconium (no cryo)

- Tungsten Carbide (no cryo)

- Agate (no cryo)

50ml:

- Steel

- Stainless Steel

- Heavy metal poor steel

|

|

|

|

|

|

Cryogenic Ball Milling

The New Mixer Mill the optimal device for the preparation of small quantities. Due to its universal character the Mixer Mill is used for a great variety of applications in biology, chemistry, pharmaceuticals, environment, ceramics and mineralogy. It performs fine and ultra-fine grinding of not only hard, medium hard and brittle samples such as alloys, bones and glass but also elastic and fibrous ones like plastics and hair. The mill is ideally suited for disrupting biological material for the isolation of DNA and RNA. With a maximum feed size of up to 8mm a grind size of down to 5 microns can be realized. The screw top design of the grinding jars prevents leaks so that even wet comminution can be executed simply and without any sample loss. Defined positioning of the grinding jars and the clamp with automatic centering ensures a maximum degree of reproducibility. The optimized self-locking clamping device simplifies handling of the jars and supports the safety aspect of this device significantly, two grinding stations for jars up to 50mm allow high sample throughput. The grinding time as well as the oscillation frequency of up to 30HZ can be preselected digitally and precisely.

An electronic speed control keeps the vibration constant during the entire grinding process. The user has the option to save up to 9 parameter settings which offer ultimate convenience in routine testing of various samples. During the grinding process the parameters are then safe from any accidental changes. At the same time this guarantees maximum reproducibility of the sample preparation process, after starting the machine the sample containers perform radio oscillations in a horizontal position, thus the material is hit alternately from various sides by the grinding balls. This high energy impact and friction action makes the Mixer Mill one of the most efficient grinders on the market. Compared to traditional mixer mills ours provides an enlarged oscillation radius on account of this a significantly higher grinding energy is applied to the sample which leads to a drastic reduction of the grinding time. Opposing action of the jars ensure stability even at maximum oscillation intensity, the whole sample is recovered. Standard applications that the Mixer Mill is used for are for example spectral analyses like XRF, ICP or AAS; subsequent pelletizing or fusion is directly possible. The Mixer Mill is therefore also and economical and ergonomic alternative to the widely used Pac and Dish Mills. Furthermore this multi-functional device can also be used for wet grinding, cell disruption and cryogenic grinding. The screw top grinding jars offer an ideal prerequisite for wet grinding; an additional teflon ceiling prevents leakage of liquids and particles. Smaller sample volumes as commonly used for the isolation of DNA and RNA are preferably prepared in disposable reaction vials such as those from eppendorf.

For this purpose adaptor racks are available and hold up to 10 reaction vials, by using grinding media of glass for instance cell disruption is affected in an extremely short time which makes additional cooling unnecessary. Temperature sensitive and elastic materials can be successfully processed by external cooling of the grinding jars, for this purpose a special cryo kit consisting on two cryo boxes, two grinding tongs and protective spectacles is available. With this equipment we offer the easiest and most efficient way of grinding the ungrindable with only little consumption of liquid nitrogen, In contrast to cryogenic grinding conducted by other mills neither preparative nor continuous cooling are necessary. The grinding results are greatly influenced by the choice of grinding accessories. Jar volumes and ball charges as well as their materials should be selected according to the nature and quantity of the sample to be ground, in order to avoid interference of the subsequent analysis. To optimize your specific grinding process the Mixer Mill offers an unrivaled variety of jars and balls ranging from 1.5mm -50ml and from 5mm-30mm, both are available in agate, hardened steel, zirconium oxide, tungsten carbide, stainless steel and teflon. Grinding balls and glass beads for use in reaction vials are available in sizes from 0.1mm-5mm. A huge amount of unique features determine the superiority of the new Mixer Mill . The convenient bench top unit is the ideal grinder to prepare small sample volumes. Our Mixer Mill is an easy to use, universal and at the same time powerful tool to conduct perfect sample preparation, it is the optimal solution to get reliable and reproducible results for your grinding, mixing, homogenizing and cell disruption process.