Table of Contents

The main purpose of truck dispatching systems is to increase equipment productivity. Since productivity is measured in tonnage or volume over time, productivity increases are made by decreasing truck and shovel cycle time. This decrease can be translated into more production with the existing operating equipment or constant production with a smaller equipment fleet. Concurrent objectives are product quality maintenance and minimization of rehandle. Also, longer term mine planning goals cannot be sacrificed for short term productivity maximization; this point is dealt with through shift planning.

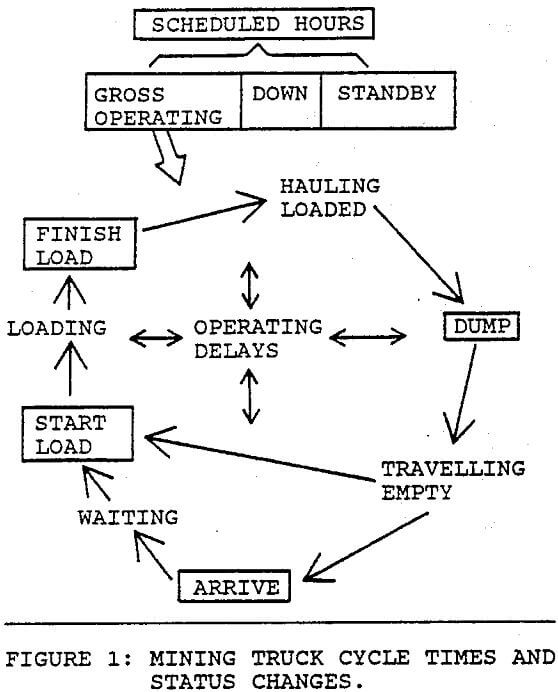

Figure 1 illustrates a truck mining cycle. The greatest productivity gains are made by minimizing waiting and delay times. Further productivity gains can be made by decreasing truck hauling and empty times.

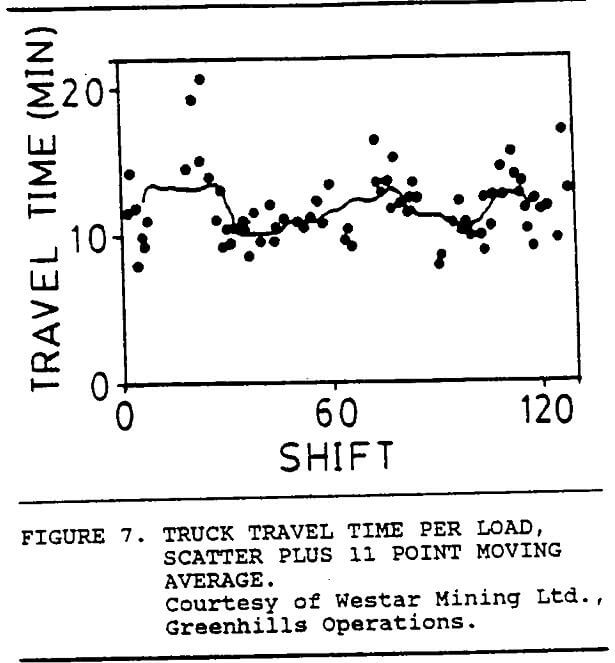

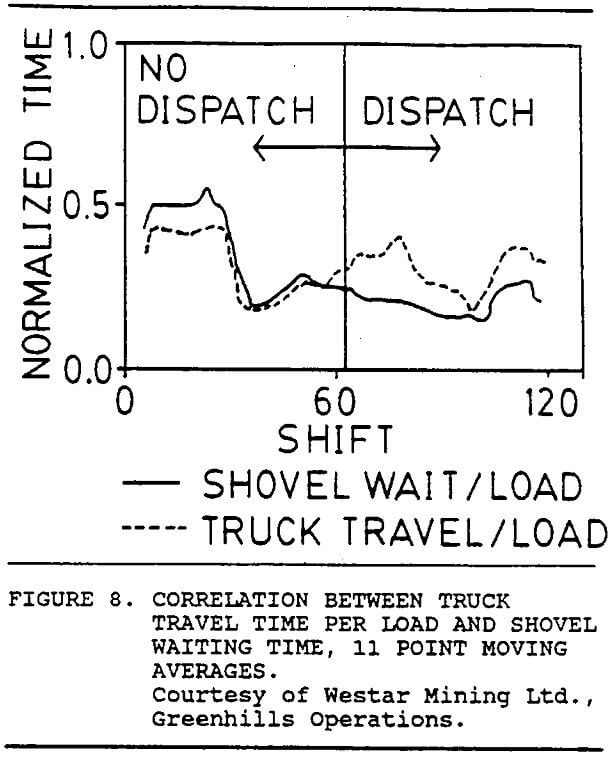

An important side benefit to truck dispatching systems, is the routine acquisition of detailed cycle time data. These data can be used to quantify the effects of changes in the mining operation. For example, the cost of incremental improvements to haul roads could be compared with the savings accruing from a decrease in travel time. Since monitoring and dispatching systems record all time increments for all mobile units, the average times can be used for accurate and sensitive statistical cost studies.

Essentials of a Truck Dispatching System

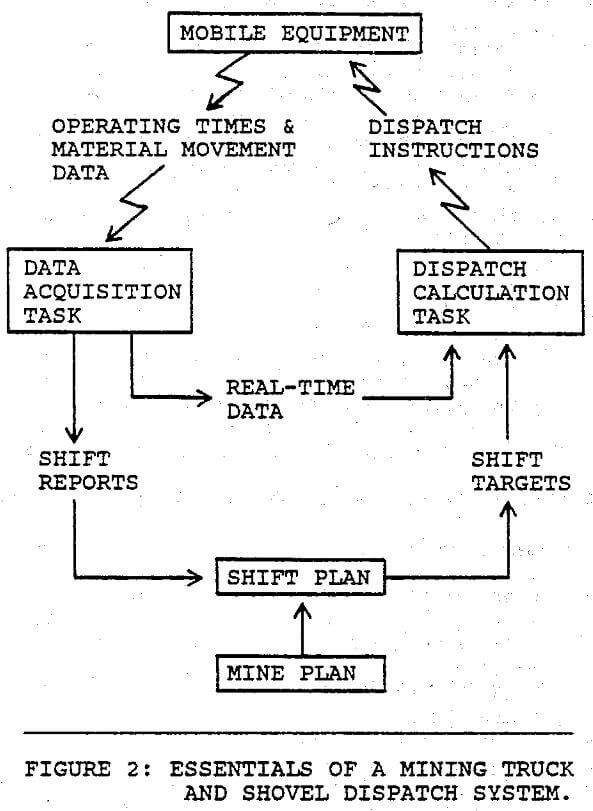

There are a number of essential functions common to all dispatching systems. They are illustrated in Figure 2. Note that all truck and shovel mines currently have a truck dispatching system of some sort in place, they range in type from purely manual to sophisticated automatic systems.

A dispatching system gathers data from the equipment operating in the pit, analyses it, compares it to the mine’s current shift plan, and then directs the equipment to locations and activities which will enable the mine to meet its objectives in the most cost effective manner.

A mine’s data acquisition program gathers information from the mobile equipment and the field supervisors. The two primary data types are time and material movement, i.e. how long has it taken to move material A from location X to location Y. Secondary information relates to fuel consumption, length of delays, etc.

The data is presented to mine management in two forms. Real-time data is used to make immediate decisions in the current shift. Summary data is tabulated into shift reports. Shift reports are used together with a mine plan to formulate shift plans.

The real-time data and the targets set by the shift plan are then used by the dispatch logic to formulate dispatch instructions to the mobile equipment.

A dispatch system is, in fact, a process control loop.

Current Industry Dispatching Practices

There are four types of dispatching systems in use today.

Manual: A purely manual system is one in which the pit supervisors gather data from the field by listening to the voice radio and by visual observation. All the dispatch logic is in the supervisor’s head. This is the current practice at most mines.

Computer Aided Manual: This system uses a non real-time computer to assist the pit supervisors tabulate data and dispatch equipment. Data is gathered over the voice radio and a computer operator manually types the data into a computer. The computer stores and summarizes the data and, when required, suggests a dispatch instruction. This dispatch instruction is relayed to the field over the voice radio.

This type of system was used in the early days of truck dispatch (Hauck, 1972). There is still current interest in these systems due to their simplicity and low cost (Bonates and Lizotte, 1988). Their chief disadvantage is their inability to handle a large number of radio messages in a short period of time.

Automatic Monitoring: There is a significant benefit to automatic data acquisition without dispatching (Sadler, 1988; Elbrond and Soumis, 1987). Data is transmitted from the pit directly to a computer over a communications data channel. The data is summarized and real-time statistics are presented to the central dispatcher. These statistics (e.g. cycle times, product blend) are used by the dispatcher as a guide to the dispatching process.

Another important benefit is the timely generation of shift reports. A detailed shift report can be printed before a crew goes home providing immediate positive feedback.

Automatic Dispatch: An automatic dispatch system combines automatic monitoring with a computer program containing a dispatch algorithm that estimates the optimum destination for a mobile unit. Dispatch messages are sent directly to the unit using the data communication system. The destination is displayed on a mobile data terminal located in the equipment’s cab.

Automatic Truck Dispatching Algorithms

There are two types of automatic dispatch algorithms in use today. They are single criterion and multi-criteria algorithms.

Single Criterion Algorithm: A single criterion algorithm dispatches trucks based on one mining parameter. One such algorithm (Sadler, 1988; Hagenbuch, 1987) minimizes waiting time. Other parameters, such as product blend, are monitored in real-time by the pit supervisors. If the importance of these other parameters occasionally over ride the automatic parameter, manual adjustments are made by changing equipment assignments over the voice radio.

The advantages of this type of algorithm are simplicity and cost. The front line supervisors can easily understand and apply the method. The programs can run on microcomputers which are inexpensive and easy to operate with no sophisticated training.

The major disadvantage is that a mine may not realize as close to one hundred percent of its potential efficiency gains as it may do with a more sophisticated algorithm. However, the efficiency gains are significant (Elbrond and Soumis, 1987).

Multi-criteria Algorithms: The multi-criteria algorithms consider several mining parameters simultaneously when they dispatch a truck. They use a combination of linear, non-linear, and dynamic programming (White and Olson, 1986: Soumis et al, 1988),

The major advantage to these algorithms is that they have the potential to realize close to one hundred percent of a mine’s potential efficiency gains.

The major disadvantages are complexity and cost. To understand and use the algorithm effectively, the pit supervisors need an introduction to linear programming. The programs currently run on minicomputers which are expensive and require a professional computing staff.

The successful installation and operation of a microcomputer based truck dispatching system at Greenhills and other mines, given these arduous criteria, clearly demonstrates that these systems are viable and economic.

Automatic mining truck dispatch technology has matured. The market has produced systems that offer a wide range of functionality and price. Mines of all sizes can now tailor a system to their particular needs.

Related: Best Lightweight Hand Trucks