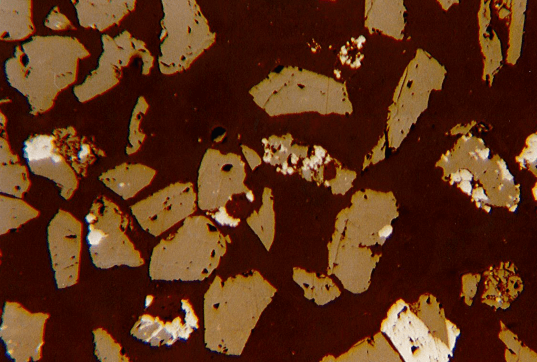

The point count procedure was to select an appropriate magnification for the micro mount ranging between 100 – 1000 times normal, and then setting a 10×10 square graticule randomly on the field. Mineral grains which were intersected by the graticule cross hairs, were identified and recorded and entered directly into the computer using a binary code.

Binary assemblages were identified by first naming the mineral intercepted by the graticule, and then the associated mineral. Ternaries were identified by naming only the mineral intercepted by the graticule crosshair.

For the purposes of point count analysis conducted on on a MVT Mississippi Valley Type Deposits concentrates, some special mineral classification criteria were adopted:

The term ’liberated’ denoted a mineral grain with less than the equivalent of two weight percent of another mineral embedded or associated with it. This decision effectively increased the reported liberation values for some minerals, since some grains contained minute adhesions and more rarely inclusions of other mineral phases.

’Binary’ signified a two-phase mineral grain which was generally of simple structure. In the context simple means that in our judgement, regrinding of these particles would significantly improve mineral liberation. Either mineral phase must contribute more than two weight percent to the grain composition to be classified as binary. The most frequently observed binary occurrence in the Polaris zinc concentrate samples were simple structures, consisting of small quantities of non-sulphide gangue attached to much larger sphalerite grains.

The term ’multiphase’ indicated the presence of three or more mineral phases within the boundary of a single grain, each phase contributing more than two weight percent to the total grain make-up. Multiphase or ternary occurrences were surprisingly quite common in the Polaris zinc concentrates and usually involved sphalerite, pyrite, and non-sulphide gangue phases.

A minimum of 900 individual particles were recorded for each of the sized fractions examined. The data was converted to weight percent content for each mineral. The estimated proportion of the mineral was then checked against the chemical assay reported for that sized fraction.

To more precisely estimate the liberation characteristics of the sparsely distributed reference minerals, a modified gross counting procedure was adopted. This procedure initially involved estimating the total number of mineral grains present in a given frame. Then a secondary count was conducted by assessing the number of the target mineral-bearing grains present in the frame. The percent liberation of the target reference mineral was then determined by recounting only the liberated target mineral grains.

By adopting this procedure, large numbers of specific classes of mineral grains could be scanned, and statistically significant liberation values assigned to sparse mineral occurrences. Typically, the gross counts which were conducted on Polaris zinc concentrate samples to study galena and non-sulphide gangue liberation characteristics, involved scanning approximately 7500 individual particles per mount.

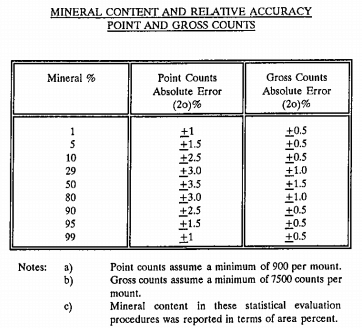

Generally, the agreement between the mineralogically measured and the assayed mineral content of a mount was good for the major components of each sample. Minor components, because of statistical variance inherent in point count procedures, occasionally exhibited poorer correlations. The table below indicates the approximate level of accuracy theoretically achievable with the point counting method. The estimates of absolute error shown in the relative accuracy table are based on a statistical evaluation of point count methods.

For each of these reference minerals five mineralogical classes were recognized: the classes were liberated grains, as binaries with each of the other three reference minerals, or as multiphase assemblages. The multiphase classification includes any mineral particle with three or more mineral components.