Table of Contents

The language concerning ventilation in many sections of the Act could very well deprive or limit the mining engineer in planning the ventilation for new mines, since the Act requires federal approval of all ventilation plans. Dependent upon approval and of course application of the law, this could, due to economics, prohibit the opening of new mines in some cases.

Planning

The importance of ventilating principles are widely known and taught at all institutions of higher learning. There is very little that has not been published on this subject. Our biggest operating problem in respect to ventilation systems are ventilating practices. No matter how well a mine is planned in respect to ventilation, if the ventilating practices are not adhered to, you can expect and will have many complex problems.

In planning a new shaft operation, the most critical calculation is that of shaft size. This determination requires the consideration of many factors; for example:

- The acreage involved in the area;

- Adequate quantities of air per machine at the extreme development from the shaft;

- Adequate number of intakes and returns in the shaft bottom areas;

- Long angled arches at shaft bottoms to reduce shock losses;

- Shaft losses due to extreme velocities where large quantities are involved;

- Air courses in high velocity approaches to and from the shaft areas;

- The R factor and the k factors.

Leakage

One of the most critical problems in mine ventilation is that of air losses from leakage. “Air leakage for operating mines in many instances is as much as 70 percent between the intake and the sum of air volumes at the last open break throughs. A leakage path is simply a parallel return path to the fan. The amount of leakage will be determined by the pressure difference between the intake and return and the condition of stoppings and overcasts.

With respect to such air losses, the choice of stopping materials at long life mine operations should be given careful consideration. Some factors to be included should be overburden, stresses, block aggregate, and pressure differential. The porosity of stopping materials can also be a factor in high pressure areas.

Many types of sealants are available on the market today; considering the long life expectancy of the mine, it was decided to use urethane-foam because it is easy to apply on unprepared surfaces and expands to seal joints and cracks. It also does an excellent job of sealing around the outer perimeters of the stopping or overcast.

Present Ventilation

The new federal ventilation requirements will tax many existing ventilation systems at various mines. It will also require a review of ventilating practices in the working sections in order to meet the standards in face regions of our mines. The major problem will be that of directing the air to the face area.

Recent studies of line brattice material and methods of installation were made at No. 6 mine to determine if more air could be conducted to the face region if better materials and improved methods were utilized. The first comparative study was made with plastic coated jute line curtain installed along a line of posts. The other system used consisted of nylon reinforced plastic brattice with grommets spaced on the top and bottom and was installed with spring-loaded adjustable metal supports.

The studies showed that the availability of air delivered to the end of the nylon reinforced line brattice was increased from 10 to 50% depending on the location of the entry. Average increase for the section was approximately 2%. Quantities of air on each operating split at No. 6 vary from 20,000 c.f.m. to 40,000 c.f.m.

In the Frick District of U. S. Steel Corporation, we have had more than 37 years of experience in the use of multiple-fan ventilation systems in our coal mines. In our Colonial field, with a long belt, installation,, we have mined 85 million tons-of coal with the use of the multiple fan system of ventilation. In our Palmer field, with the use of the same arrangement, we have mined 90 million tons of coal—a total of 175 million tons without one accident attributable to improper mine ventilation,

The same system, fundamentally, has been installed in our expanding Robena operations and at its present stage of development we are using eight fans to ventilate this area. To date we have mined 55 million tons of coal with very encouraging results and again without any accidents attributable to ventilation.

In introducing multiple fan ventilation to our operations, we sacrificed or mitigated none of the basic ventilation standards held by us to be attributes of sound, safe mine ventilation, regardless of mine size. For examples: two-split section ventilation; emergency fire door arrangements and regulators to be used in conjunction with two-split ventilation to afford a smoke-free escape route in event of an emergency; a 5 pct maximum allowable methane concentration in the return of any air split; a minimum allowable air flow of 10,000 cubic feet per minute on haulage roads; and so forth. Contrarywise we have found that multiple fan ventilating systems have contributed generally to increased safety and flexibility in coal mine ventilation.

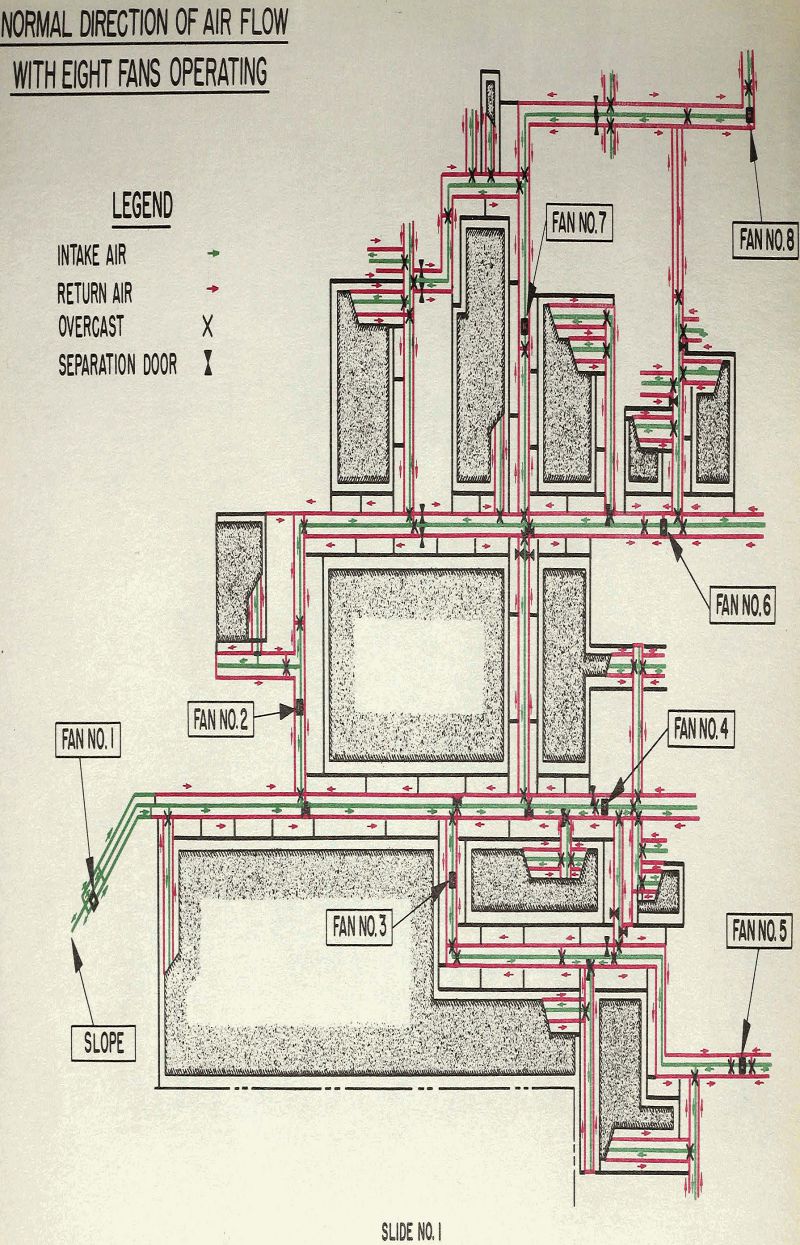

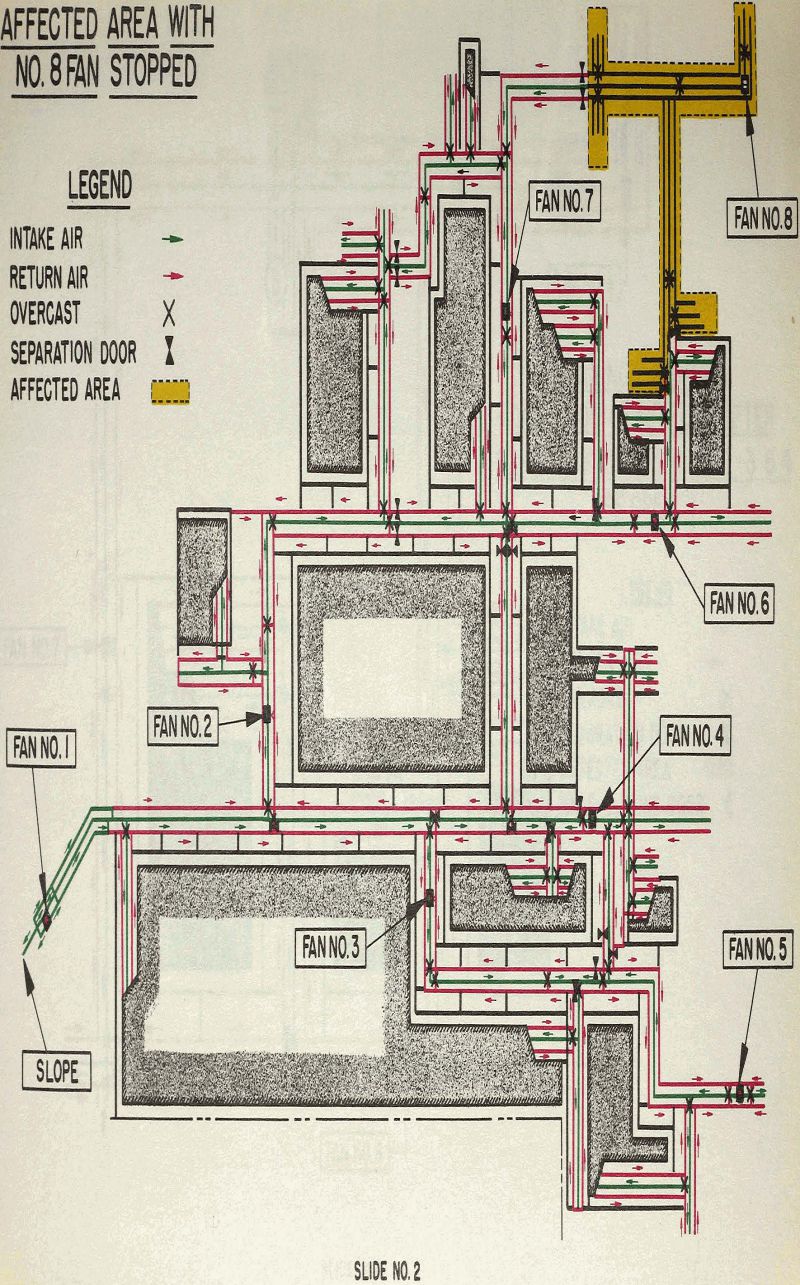

As a specific example you will note the direction of air flow under the influence of No. 8 Fan. The direction of intake air is indicated by the green arrows. The red arrows indicate the direction of return air flow. You will, note that the governing separation doors are in the closed position.

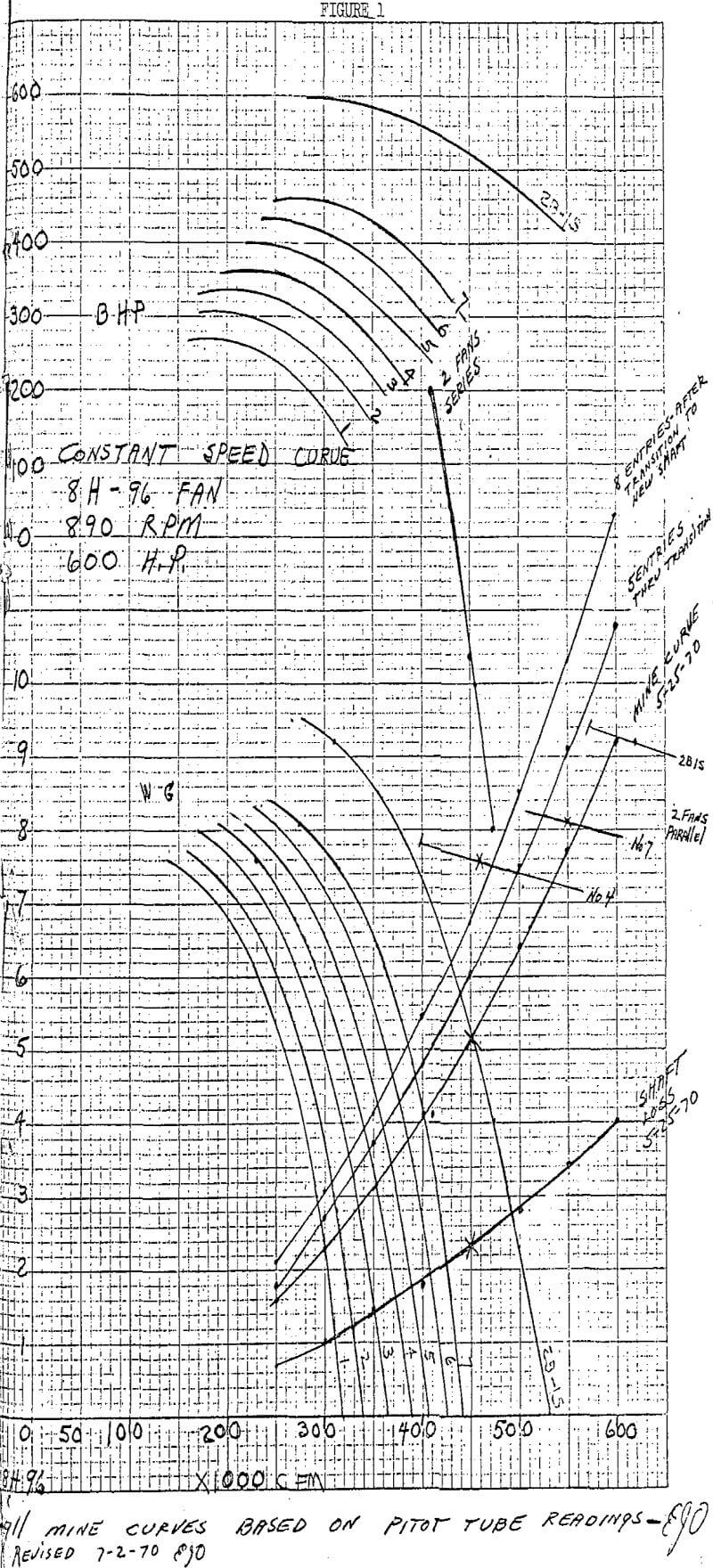

The foregoing merely highlights the wealth of data accrued from the many ventilation tests made at the Robena mine. We wish to emphasize that these tests are constantly being made especially for or as a part of our routine fan maintenance program. Such tests serve the purpose of keeping all information current so that for any immediate situation, we have accurate, first hand knowledge of the direction and quantities of air available to the mine when any fan is down.