Here is how Mg is often present as Mg (magnesium oxide) in a Zinc Sphalerite Concentrate produced by froth flotation.

According to typical mineralogy data obtained from Zinc concentrate (P80=90um), the MgO is located in 2 opposite regions. This concentrate contained 0.3% Mg total. Unless you want to give away your concentrate to Doe Run, you need to clean up this concentrate.

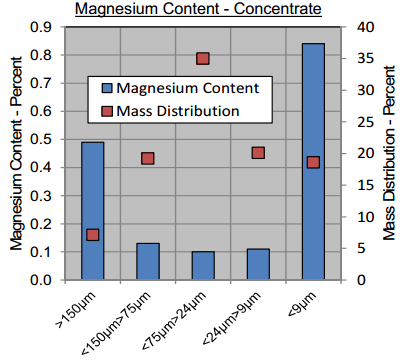

- The coarse >150um size fraction assayed 0.5% Mg and contained 8% of the Mg ‘problem’ Contamination

- The ultra-fine <9um size fraction assayed 0.85% Mg and contained 18% of the Mg ‘problem’ Contaminating.

Here are some simple ways to effectively remove or reduce Mg content from a flotation concentrate.

In absolute terms, the needed Mg reduction is small since smelters will usually “scream” at 0.5% Mg but start penalties over 0.3% Mg.

While Coarse MgO Contaminated the concentrate, it can be reduced by the application of a regrind on the Zinc Rougher Concentrate. This regrind mill would need be applied to about 20% of the Zinc rougher concentrate (only the coarse fraction).

The purpose of this light regrind is to liberate MgO from Pyrite and Sphalerite prior to cleaning. This will allow selective cleaning and rejection of unwanted MgO and Fe locked with Zn in dilution cleaner to insure minimal entrainment.

Since Dolomite is around 13% Mg, it really does not take much to contaminate a sphalerite float concentrate by 0.1%.