Table of Contents

The planning of an underground mine for successful extraction of a bedded deposit in sedimentary rocks requires the integrated evaluation of many interdependent problems. The development and coordination of feasible solutions are the responsibility of the mining engineer. One of these problems will be discussed herein; this is the design and layout of mine workings to secure effective control of the strata above and below the deposit. The objective is the simplest possible repetitive system permitting safe maximum recovery at optimum cost. Mining conditions to be encountered must be predictable. The best mining equipment is ineffective unless strata are controlled. Conversely, a mining layout is only of academic interest, if equipment can not be adapted to work it with adequate provision for ventilation, compliance with mining laws, proper ingress and egress and other practical requirements. Strata control, then, is but one of the mining engineer’s problems, and the solutions must be worked out concurrently with solutions to other problems.

Classification of Methods of Mining Bedded Deposits

The first step in planning a mine for extraction of a bedded deposit is the selection of an appropriate mining method. The methods vary principally in the effect on the main rock mass overlying the deposit. The following classification is developed from that suggested by Spackeler.

- Room-and-Pillar Mining – Partial Extraction

Pillars are formed but not extracted. The pillars are of such size that the weight of overlying strata is supported and downward movement of the roof is completely or almost completely prevented. - Room-and-Pillar Mining – Pillars Extracted

Pillars are formed on first mining and then extracted on second mining so that there is no effective resistance to the downward movement of the entire rock mass from seam to surface. - Combination of 1 and 2

Pillars of a size slightly less than sufficient for support of the overburden weight are formed. The pillars are left in place and gradually deform allowing the roof to bend downward. - Complete Extraction – Longwall Mining

In longwall mining, the main roof is systematically lowered to a new position on the floor. Equilibrium is constantly being destroyed and re-established as the coal or other mineral is removed and the main roof bends and slowly moves downward.

Transference of Roof Loads

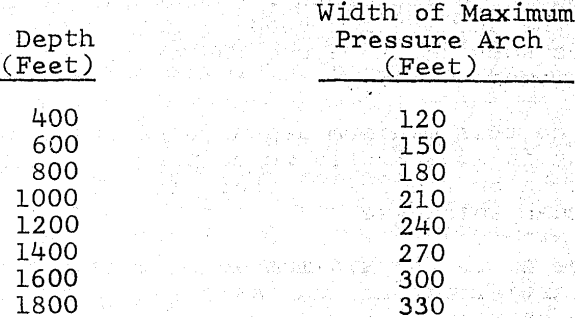

The most important factor in selection of mining method is the depth of cover. However, the type of cover affects the effects of simple depths. The average rock pressure due to vertical loading can be determined from the density of the overlying strata and the depth of cover. Generally, this approximates one pound per square inch per foot of depth. It is interesting to note that pressures of this magnitude are sufficient for effecting fracture connection between solution mining wells. At considerable depth, it is obvious that no practical form of artificial support could support the weight of strata. At 1,000 feet, for instance, the weight overlying a square foot would approximate 72 tons. Mining at depth, then, is possible only because most of the load is transferred to the sides of openings as abutments or areas carrying more than the normal cover load. The function of roof supports is limited to the control of immediate-roof beds.

The concept of bridging roof action has almost universal application and importance. Higher beds of overlying strata tend to arch or bridge across narrow openings underground.

The concept of “arching-out to surface” appears logical to the USA coal miner. If good caves are achieved in room-and-pillar mining when pillars are extracted, and there are no massive strata causing cantilevering roof masses, good working conditions generally result at shallow cover. The conclusions of Howarth are pertinent. Measurements of subsidence from pillar extraction at Montour No. 10 mine at a depth of cover of 100 feet indicated that no draw occurred over the solid coal. “It would appear that there is. a minimum depth of cover required to produce draw over a retreating rib line.” This minimum depth would correspond to the depth at which the height of the arch no longer reaches the surface and bending rather than breaking of the upper beds produces subsidence beyond the caved area and weight concentrations underground.

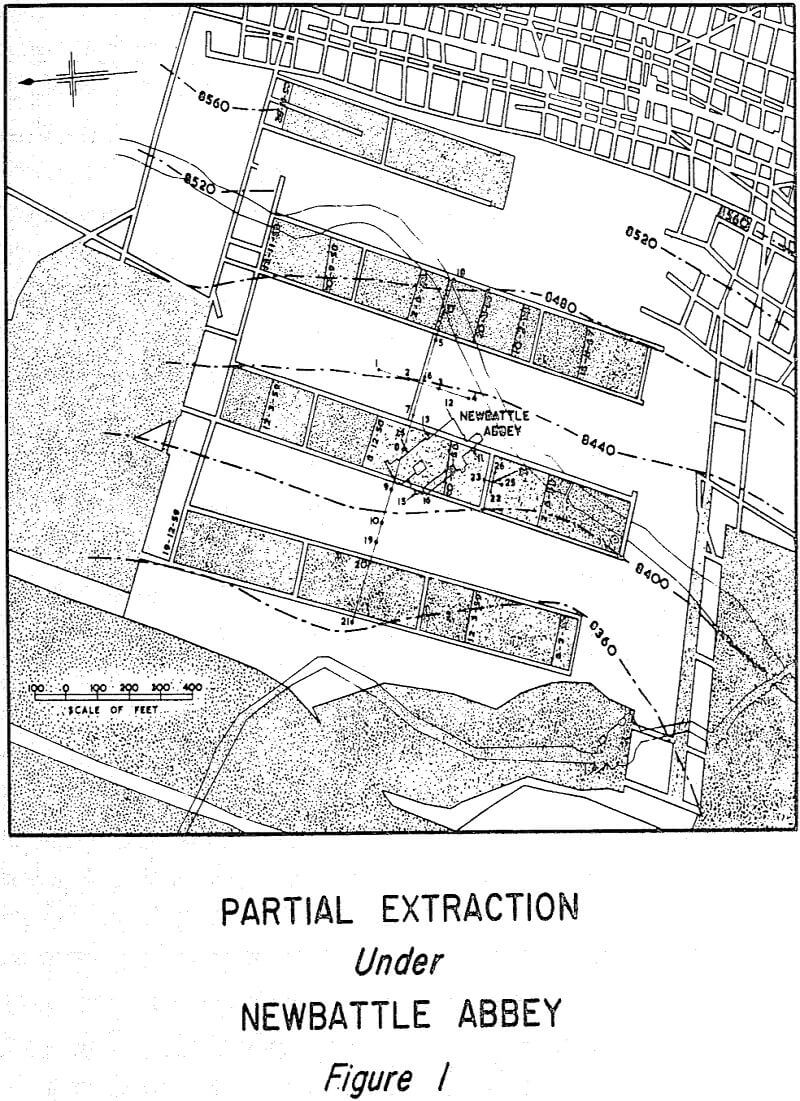

Room-and-Pillar Mining – Partial Extraction

Partial extraction is a method generally thought of, at least by the USA coal miner, as applicable under shallow cover. Actually, partial extraction is also feasible at great depth of cover. Primary reasons for partial extraction are usually one of the following:

- Prevention of damaging surface subsidence.

- Necessity for mining under water-bearing strata.

- Necessity for mining under extremely massive and competent strata.

Early coal mining in Great Britain was almost exclusively on a partial extraction basis. Pillars were formed with no intention of future extraction. The areal extent of mines was, of necessity, limited. Early attempts at pillar extraction in north England were abortive. Second mining was not attempted until workings had reached the boundary, and this often resulted in squeezes over large areas due to failure of either the pillars or more often the floors which were quite weak.

With the panel system of mining, room spacing and consequent pillar size can be determined by experience with little risk at shallow depth of cover, since squeezes and surface subsidence are isolated to a small area. At depths greater than about 500 feet, as previously mentioned, extraction of as much as 50 percent of the coal may result in an unstable condition wherein weight is carried over.

The percentage of extraction for bedded deposits other than coal can often be greater in relation to depth than is possible for coal. The limiting factor of a weak roof or floor is less likely. Mining of plastic materials such as potash on a partial extraction basis at depths as great as 1,000 meters is an accomplished fact. However, at such depths the percentage of extraction possible when leaving evenly-distributed and sized pillars for support may be as little as 30 percent.

The strength of a pillar is a function of its ability to build up lateral restraint. If a pillar is sufficiently wide, a point is reached toward the core where expansion laterally does not occur. Consequently, the strength inside the core is essentially infinite. This build-up of strength is principally a function of width and height. The exact ratio at which the pillar approaches ultimate strength is a matter for conjecture.

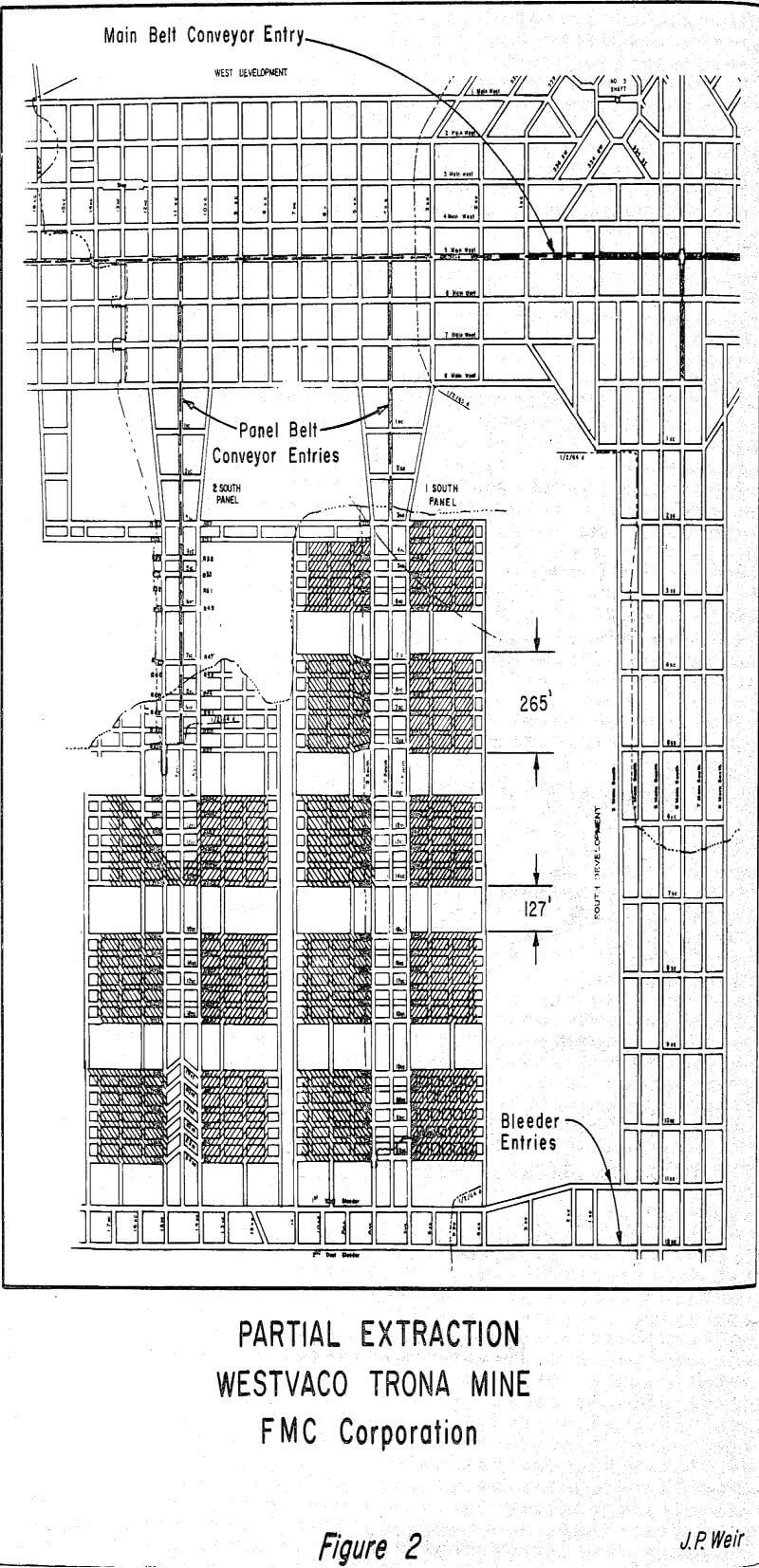

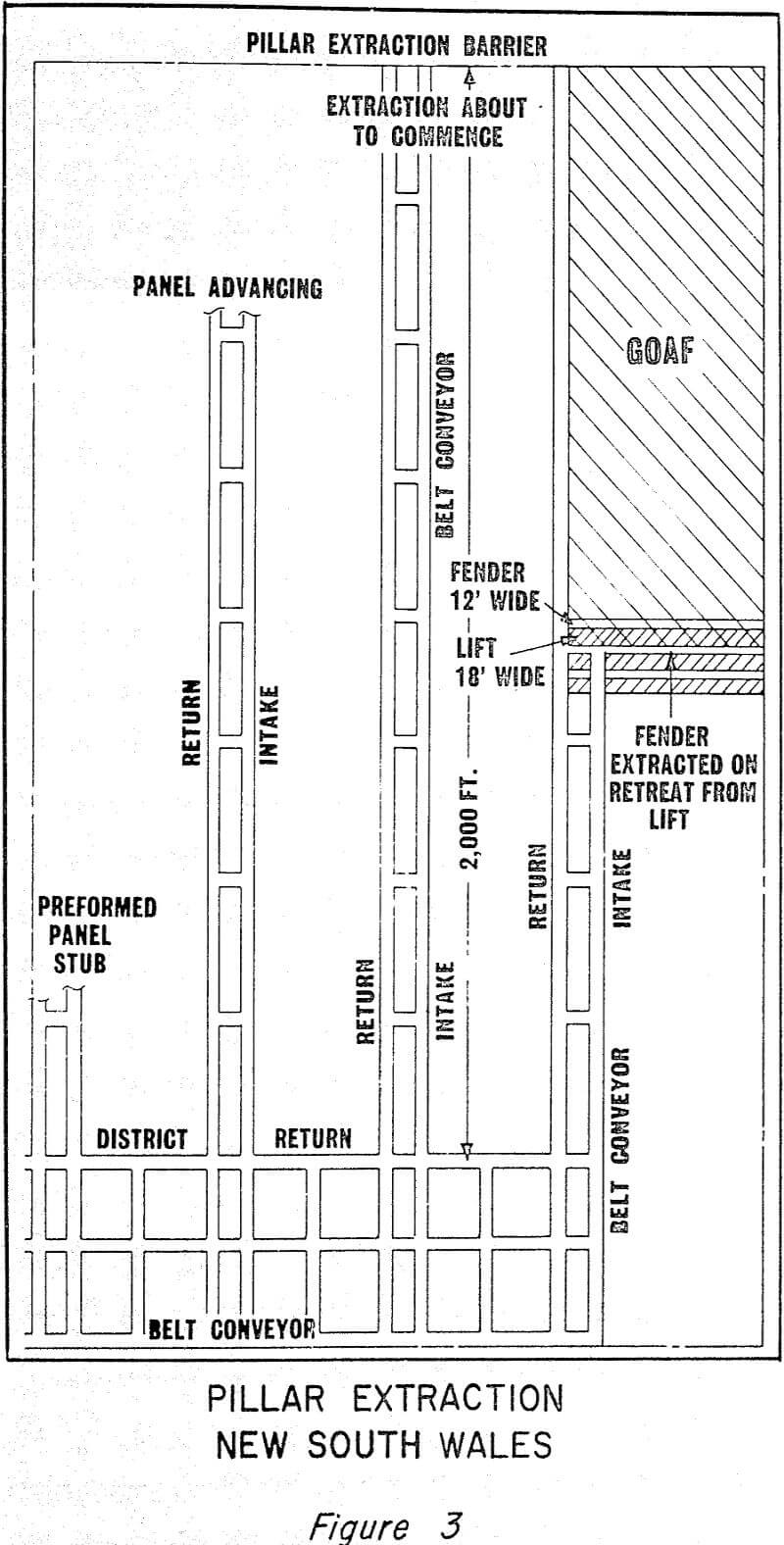

Room-and-Pillar Mining – Pillars Extracted

Reference has been made to the invention of the panel system by Buddie in north of England in 1810. This method was popular for a short time, but even then the English coal mines were developing downward rather than laterally. As deeper seams were worked, the recovery on partial extraction suffered, and the usual method changed to full extraction wherein large pillars were formed for subsequent extraction. Roof loads were reduced by reducing entry and room widths and increasing size of pillars. At great depth this principle finally became uneconomic since places sufficiently wide could not be held open, and the longwall method was adopted despite increased dead work.

Fortunately for the USA coal miner, the depth of cover for most mines is relatively shallow, and there is usually little difficulty in achieving “good caves” which prevent excessive pressures in areas where pillars are being actively worked. Exceptions to this would include mines where massive strata lie above the coal seam and are difficult to break. Other exceptions are several coal mines in Carbon County, Utah, where because of massive sandstone overlying the coal and depths of cover of as much as 2,000 feet, attempts at recovery of pillars have resulted in low overall percentage of extraction. The federal government, lessor for much of the coal in the area, is now satisfied with partial extraction by the lessees since ultimate recovery will probably be as good as was achieved under full extraction. One operator is employing the longwall method of mining.

All previous mention of depth of cover herein has been intended to refer to depth under an essentially level surface of indefinite extent. One reason for the success of the room-and-pillar system in USA is that much of the mining is in mountainous areas where access is by drift. Depth of cover under mountains can not be considered as equivalent to depth of cover under a plane surface. There is a lack of lateral restraint along the outcropping of the roof strata around the mountain, and this results in some dissipation of lateral compressive forces. Lateral forces increase with depth and can be extremely destructive in fracturing mine roof at depths of say 1,000 feet below the level plane.

Complete Extraction – Longwall Mining

Longwall mining is the method best adapted to full extraction of coal at great depth. Weight of overlying strata is carried ahead of and behind the face area, and assuming favorable characteristics of overburden, excellent working conditions on the face itself are possible at depths up to 3,000 feet or more. Because of the transfer of weight from the face area, support systems and loading at great depth are often similar to those at shallow depth. As will be seen later, too shallow cover may be detrimental under certain conditions. The real problems in longwall mining are often concerned with maintenance of entries in abutment zones.

In room-and-pillar mining when pillars are extracted, the main roof mass should remain essentially undisturbed and immobile within the working area. If subsidence occurs over the working area because of depth or massive strata, mining conditions become difficult. In longwall mining subsidence always commences over the solid and continues until the overlying strata rest on the floor. In essence, the coal and immediate roof beds are caught in the jaws of a vise as the main roof bends down, looses its support from the solid coal, and eventually comes to rest on the caved rock in the gob.