The information that is in this, our last and most important, chapter deals with safety. To open this chapter I would like to make a few general statements concerning work habits, safety awareness and safety programs.

The information that is in this, our last and most important, chapter deals with safety. To open this chapter I would like to make a few general statements concerning work habits, safety awareness and safety programs.

The operation of a concentrator plant can be very dangerous or it can be very safe. How it is going to be depends upon you. No one else other than the person doing the job can make that job safe.

I feel that there are four factors that make for safe working conditions, job knowledge, work habits, safety awareness, and a supported safety program. Of those four how many will work, only, if you as an individual support them? The instruction and information that is in the earlier sections of this manual will give you a base to build your knowledge on. Your work habits are built from this job knowledge, personal instruction and day to day experience. A safety program is a co-operative system of rules and procedures that are developed between management and employees. The goal is to free the work place of potential dangerous areas and promote safer attitudes of the employees. This is to safe guard both themselves and machinery from possible harm. Safety awareness is each individual learning to view every job and every action from a safety aspect. Once it has been learned it becomes second nature. Every job that is done is automatically evaluated as to its accident potential.

The purpose of this portion of the manual is to begin laying the foundation of information that is required for you to make this evaluation.

Throughout the manual we have been giving safety tips, now we will repeat them and add some new ones.

First, for the Ore FEEDERS. All walkways and work areas should be kept clear for easy access and exits, don’t leave things laying on or around feeders.

If you have to bar in a feeder or a chute.

- Always keep your scaling bar or pry bar to one side of your body, never in front of your body. The reason is this, if the hang-up comes down suddenly and hits the end of your bar it may either impale you or be pivoted off of your hands into your face.

- Wear gloves and make sure that your hand is not on a pinch point. A pinch point is any where there is a danger of becoming caught between the bar and any other object.

- Wear safety glasses or goggles, preferably goggles. When a hang up comes down it displaces air, this causes a wind. This wind picks up small particles of dirt and rock and showers you with them.

- Have an emergency escape route planned in your mind. If you have to move backwards in a hurry you have a safe path figured out. This will prevent confusion.

- The last thing that I would like to mention in this safety talk on feeders is never attempt to use explosives without the proper training and authority to do so.

Our next hatch of repeats deal with CONVEYOR SAFETY:

Our next hatch of repeats deal with CONVEYOR SAFETY:

Around all moving equipment will he guards of one type or another. They may he there to prevent people from falling into the equipment or, in cases where there is a danger of equipment failure, the guards may he designed to contain parts and pieces that may fly off of them.

The problem with conveyor belts was that a system had to be designed to protect the worker and still keep the conveyor open for clean-up and provide the necessary access. What was developed was the Safety trip cord. This cord is situated along the sides of the conveyor. It is placed at least level with the conveyor belt or possibly a little above. Its purpose is to shut the conveyor down if anything should hit it. At the trip switch will be a metal flag that will drop into the tripped position once the cord has been pulled. It is there to indicate to the operator that it is tripped and requires resetting. The operator should always visually check the conveyor before starting it hack up. You never know, maybe your foreman or helper is caught in the conveyor hut managed to grab the cord to shut the belt down. As you can imagine a single cord does not give one hundred percent safety coverage, and conveyors are dangerous. To keep the danger to a minimum there are a few rules that should he followed.

- When cleaning a head or tail pulley never stick a bar or shovel into the pulley. If it should get caught, which is easy to do, it will pull you in so fast that you won’t have time to let go. The conveyor should be shut down to clean these pulleys.

- Always shovel in the direction that the conveyor is traveling. In other words when shoveling onto a belt be sure you are facing towards the head pulley. If you are facing the other way, there is a danger of getting your shovel caught in the load or the conveyor itself. The shovel will then be propelled towards you like a spear.

- No riding on conveyor belts. More than one operator has fallen into fine ore bins or transfer chutes by not being able to get off in time.

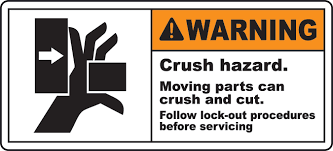

- When ever you are working on or in any moving piece of equipment it should be locked out. Locking out equipment means, by following the procedures set by management, the operator places a personal lock on the circuit breaker that controls the equipment that he will be working with. Of course the circuit breaker must be “racked out”. This means the circuit is opened to prevent an accidental start-up. Once the circuit has been broken the operator should try and start the equipment to be sure that it can-not start-up.

- When a crusher breaks a rock, small pieces may become airborne. This is known as fly rock and can be quite dangerous, especially to the eyes. For this reason proper safety glasses or goggles should be worn at all times.

- When working around crushers stay behind safety barriers, or wear a safety belt, you wouldn’t want to fall in.

- Never grab anything from a moving conveyor, especially if you can’t see both ends. That small length of rock bolt may have a rock still bolted to it. If you don’t see the rock in time it you may get pulled into the conveyor. Perhaps that innocent length of cord has a live blasting cap on the other end of it. Accidentally banging it on a rock could set it off.

- Never work under a hang up. Bring it down before you start work.

- Be extra careful digging out crushers. Have a safety man watching and wear a safety belt. When you climb into a crusher the ore may be bridged. If you move the wrong rock the bridge will collapse with you on top of it. Sliding, rolling rock is also a danger when doing this job so be careful.

The safety topics that I picked to discuss in the chapter dealing with the SECONDARY CRUSHER were noise and dust.

These two are harder to deal with than most because of their nature. A hazard that involves blood and pain is an immediate thing and very easy to understand. But something that may take years of development before it becomes a problem just doesn’t seem that important at the time. As time passes and the effects of the noise and dust start to be apparent they are often mistakenly attributed to ageing. The worker will think that he or she is just getting old, not becoming a victim.

You see, both of these dangers effect the worker in slow stages. With dust the sharp edges of the particles scratch the surface of the lungs, and after a time, scar tissue will form. The scar tissue prevents the lungs from processing the oxygen from the air. Breathing will slowly become harder and harder and stairs will become longer and longer. Once the scar tissue has been formed it is there for good and so is the shortness of breath. .

With noise, things just become quieter and quieter until nothing is left.

Even the FINE ORE storage area has certain dangerous aspects to it. If there is work to do inside of the fine ore

bins the bulk of the work will be preparing the bins so that it is possible to work safely in them. This job doesn’t come up to often but when does it can be a real problem. From the top of the bin to the bottom is a long way down. Even a small rock can injure a person should it fall from the top. Therefore it is necessary to be sure that any rock that could fall is brought down under controlled conditions. There may be no more than a shovel full or it may be tons of material, whatever the amount, it means that someone has to go to the ore and remove it. Here are the rules that make this job safe.

First safety lines, your equipment must fit, and be in good condition.

There must be a worker employed as a lookout and line tender. It will be his responsibility to ensure that the people working below are safe, and are aware of any danger that might threaten them. To tend safety lines properly, there should be one person per line, and the lines must be free of each other. Here are some of the things that may happen if these few rules are not followed.

If you are wearing as safety belt instead of a harness, The fit is imperative, should it be too loose, and if the worker did slip he may flip upside down and fall out of the belt. If the line tender doesn’t keep tension on the safety lines and the worker falls, the worker may break his back or some ribs when he hits the bottom of the slack. The greater the slack, the farther the fall, the greater the possible injury. If the safety lines are all tangled up, and a worker falls, then anyone else that his lines are tangled with may be pulled in- with him or her.

It is very easy for a worker intent on the job at hand not to be aware of impending danger. The lookout tending the safety line is in position to observe everything that is going on below. He or she will be able to warn their fellow worker should something be developing that the worker may not be aware of.

As for the workers in the bin there is a few things that they should be aware of as well.

First never work directly under a hang up, the loose material could slide at any time, if it does there may not be

enough time to react.

Never disconnect your safety line while you are in the bin.

Always ensure that your point of exit or entry is secure, if it is a ladder, be sure that it is securely fastened or tied down. If it is a hatch or door, ensure that there is nothing hanging over it that may come down either trapping you in the bin or landing on you while you are coming or going.

This is the last safety tip that I would like to mention to do with live ore stock piles and bins. Never, ever walk out on top of a pile of ore where it is being removed from the bottom. Under these conditions the ore that is being removed may cause what is known as an ore bridge to form, this is simply a cave caused by the removal of the ore. These bridges are not very stable, in fact they usually collapse under their own weight. If you walk out on top of one then your weight may be more than enough to collapse the bridge. If this should ever happen you would be buried before you had a chance to realize what had taken place. To top it off, unless someone happened to be watching you at the time, nobody would know what had happened to be able to come to your aid and rescue you.

This brings us into the GRINDING AREA: This area has many of the same safety problems as there are in the primary and secondary circuits. Conveyor belts, feeders, dust and noise make up the largest portion of the dangers that are involved, like every other circuit, though, there are some dangers that workers will find are more common here than elsewhere. Of these the most common is foreign objects entering workers eyes. Usually this will the slurry, from inside the mills, splashing the workers face while he or she is working around the circuit. When the worker is taking densities and doing his clean-up he often is vulnerable. Safety glasses are not one hundred percent effective unfortunately, this means that goggles often are required.

The mills themselves provide another danger to the worker, these are large and they move. There is always the possibility of getting ropes and cables for the cranes caught in them.

There is a lot of activity in this part of the complex, people coming and going. Many of these individuals will not be familiar with the normal safety procedures that the operating crew will take for granted. This means that the operating crew has to be very alert when starting and stopping equipment. There has been more than one person killed because he wanted a look-see at a mill just as it was being started.

If the operating crew is inquisitive as to what is going on within their area, such things as, what repairs are being made, who is working where, and why, many potential accidents or incidents will be prevented. Remember as a member of an operating crew you know what is happening or about to happen. A visitor or an employee from another section may not. A warning horn or bell may mean something to you, but to the visitor it may be just more noise, so keep an eye on them and don’t hesitate to warn them about the obvious.

The grinding circuit is also the section that brings us to the chemical side of milling. In these days of great technological advances what is used as a reagent one day may not the next. What may be a positive statement about the dos and don’t of individual chemicals and how they should be handled may not be true in the morning. Because of this the safety information will be directed towards all reagents. Not just specific ones.

As you know, reagents come in different forms they may be liquids, gases, or solids. They may also be poisonous, caustic, and explosive. They may react with each other, or with water. Some give off poison gas when exposed to air, others are simply irritating. Some Poisons are so irritating that a few parts per million in the atmosphere will cause people to choke and gasp, and eyes will begin to water. Long before the level of poison reaches dangerous proportions the area is impossible to be in. Others have no taste, smell, or colour and will be deadly.

People may be poisoned by consuming the poison orally, breathing it as a gas, or absorbing the toxins through the skin.

My advice to any one handling reagents is to treat them all as if they are deadly poison. This means wearing rubber gloves, face shields and respirators. Once you have finished handling reagents wash your face and hands especially before you eat. To prevent skin rashes and problems keep your work clothes laundered, dust and mist will become trapped in the weave of the cloth. If they are not removed the minute particles will end up in the pores of your skin.

Again the best protection is knowledge, learn all that you can about the reagents that your plant uses. This way you will be able to develop a safety awareness of the reagents:

To help with your awareness there are a few general rules that will help in your protection. The first one is:

To help with your awareness there are a few general rules that will help in your protection. The first one is:

- Know the chemical and physical properties of the reagent that you are handling.

- Consider all reagents poisonous and treat them as such.

- Wear then correct protective clothing and equipment.

- Avoid breathing gases, dusts and mists,

- To prevent them from interacting, keep Reagents separated in storage area.

- Keep storage area clean.

- Spillage should be disposed of in an acceptable manner. This will be set down by a supervisor.

- Do not get reagents wet when cleaning reagent storage area.

- Do not smoke around reagents, some are extremely flammable. When reagents begin to burn them often create all of the necessary components that a fire requires to burn. Heat may also cause them to generate poisonous gases as well.

- Many reagents are caustic, therefore always use the correct container. Using the wrong container, may cause the reagent to react to it. If this happens the reagent may eat through the container causing a spill, or he contaminated by having a property from the container added to it.

- Know where the drench showers and safety equipment are, and how to use them.

- In case of personal contamination, flood the affected area with lots of water. The reagent must be washed away. If water is used sparingly the reagent may react with it. This could create a bigger problem than the original one was.

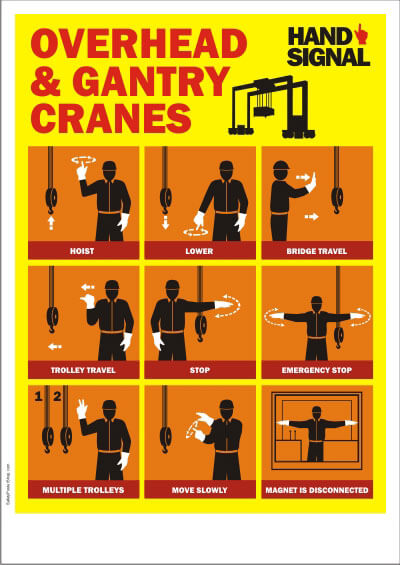

The last subject that we will mention here was originally mentioned in the chapter that dealt with general working conditions. What is being presented is a repeat of the dos and don’t involved in crane handling:

- Don’t lift a load unless you can clearly see the entire thing or you have someone directing you.

- If you have a person hooking your load up and directing your hook movement, he or she is the boss. Don’t move your hook unless directed to this person is sometimes called a hook tender or crane chaser.

- If you can’t see your hook tender don’t move until you can.

- When lifting a load be sure that nothing can fall off of the load.

- When moving material around equipment use a guide rope whenever possible.

- Never ride or allow anyone else to ride a load.

- Never walk under a suspended load.

- Always be sure that any material that has been piled is secure and will not fall over.

- Always check slings and cables for damage. Discard any that show any signs of wear.

- When walking with a loaded crane walk beside your load, keeping an eye on it and where you are going, never walk backing up.

- When you are finished using a crane be sure the hook and the controls are up out of the way. This will prevent anyone from hitting their heads or damaging the controls.

This chapter on safety is by no means to be considered a complete one. There are many subjects that I haven’t touched and the ones that I have discussed could be developed in greater detail. These topics are basic as I have said several times throughout the sessions. I hope I have added to your safety awareness.