Mechanical Concentrating Pan, although primarily developed for the recovery of placer gold, is proving equally successful for treating mine dumps, old mill tailings, and values from low grade sluice operations. The Mechanical Concentrating Pan has also proved valuable as an amalgamator in free milling gold plants.

The phenomenal success of this unit is based upon the fact that it duplicates the hand panning motion in a smooth but positive oscillation which settles the free mineral. The amalgam plate and rubber matting catch and hold both the fine and coarse values.

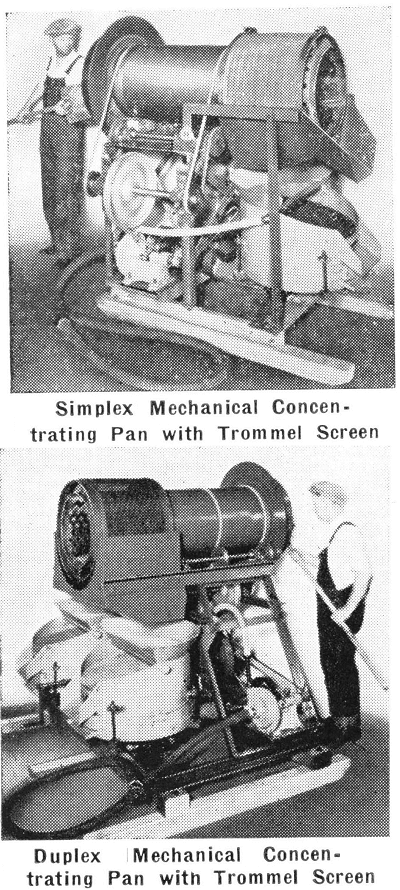

Mechanical Concentrating Pan duplicates panning motion by using a steel yoke and saddle connected to an enclosed, rotating, ball bearing eccentric. Material is fed into the hopper on the upper screen (a punched steel plate) which allows ¼” material to pass through. On the second screen the feed is again sized, until only the fine material and the water pass to the concentrating stages below. There are usually three concentrating pans placed one on top of the other. The top pan contains a plate of heavy copper coated with mercury to amalgamate free gold. From this first pan the overflow enters the second concentrating pan, which is made of steel, with Rubber Matting in the bottom, over which is placed a 1″ screen to hold the matting in place. This screen also acts as a riffle to whirl the material and settle the gold.

The third or bottom pan is assembled the same as the second and is used to ensure complete recovery of the remaining values or any floured mercury. All pans are constructed so that either the copper amalgam plate or rubber matting can be installed to suit conditions. The Mechanical Concentrating Pan is a self-contained machine, being equipped with a gasoline engine, V-belt drive, water pump and suction hose with a foot valve. All units are mounted on a welded, structural steel base and provided with skids for mobility.

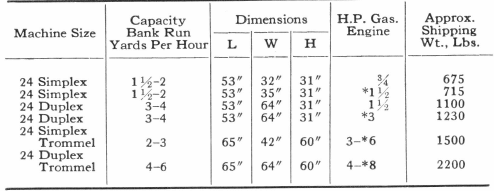

This unit, as a duplex machine, consists of two separate Mechanical Concentrating Pans driven by the same power unit. The distinct advantage of the duplex unit is that one set of pans can be cleaned up while the other set is still in operation. This is a valuable feature when using the unit as an amalgamator in circuit with a stamp battery. Experience has proved that the Mechanical Concentrating Pan operates successfully under most conditions. However, operators have requested a machine with a trommel washing screen for gravels containing clay and sticky material. Trommel screen attachments can be supplied for both simplex and duplex units.

An outstanding recommendation for the Mechanical Concentrating Pan is that this unit has more than six hundred users all over the world. Many of these installations are repeat orders.

Gold Panner Capacity

Above 7,200 feet altitude, this higher horsepower engine should be used.

NOTE: Mechanical Concentrating Pans equipped with electric motor drives available for use wherever applicable.

Source: This article is a reproduction of an excerpt of “In the Public Domain” documents held in 911Metallurgy Corp’s private library.