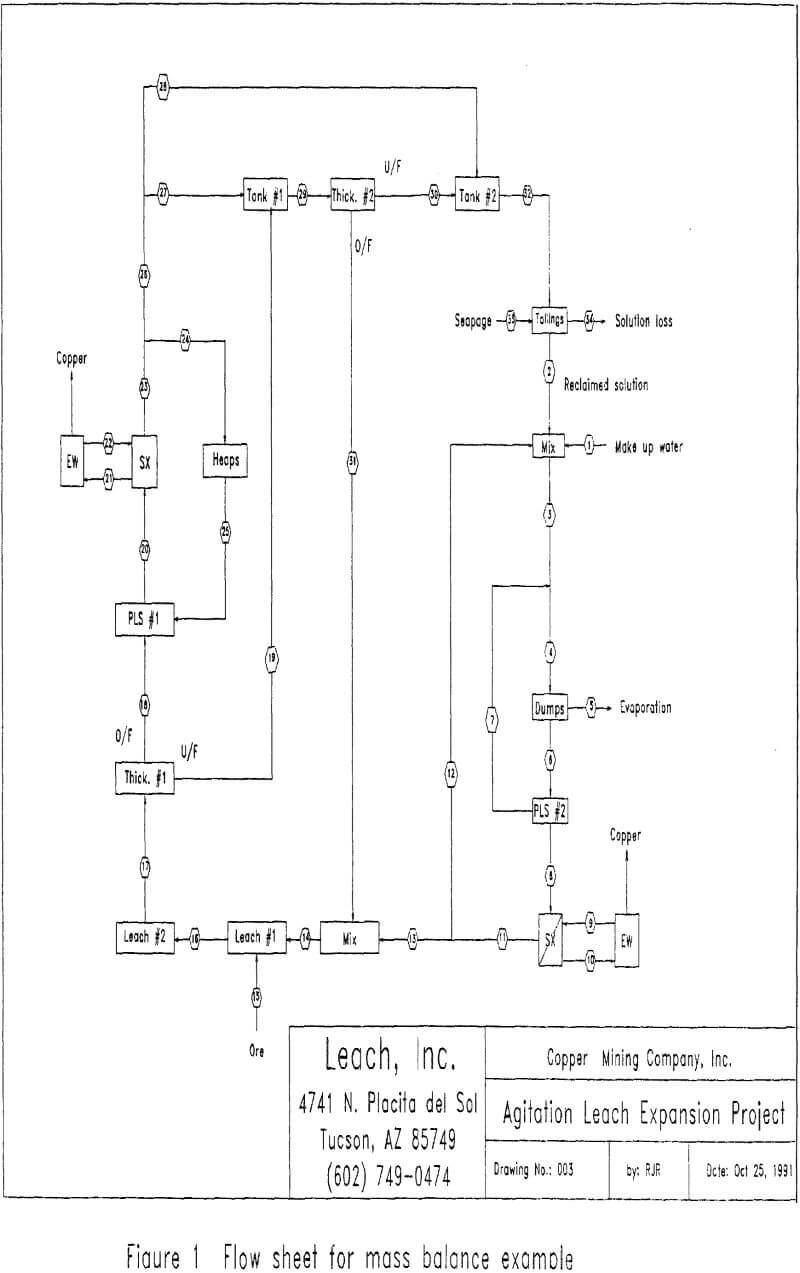

The “mass balance” is unquestionably the most common class of problems for the process engineer. Closely related, mathematically, is the “heat balance”. Every laboratory test requires a mass balance to describe the results. Mass balance calculations can be subdivided into several sub-categories based on whether the results are time dependant or not and depending on whether the input data are measurements that contain errors or are hypothetical values with no errors. Time dependent mass balances are dynamic process simulations and in addition to the conservation of mass constraints require kinetic data input. They are one step beyond simple mass balances.

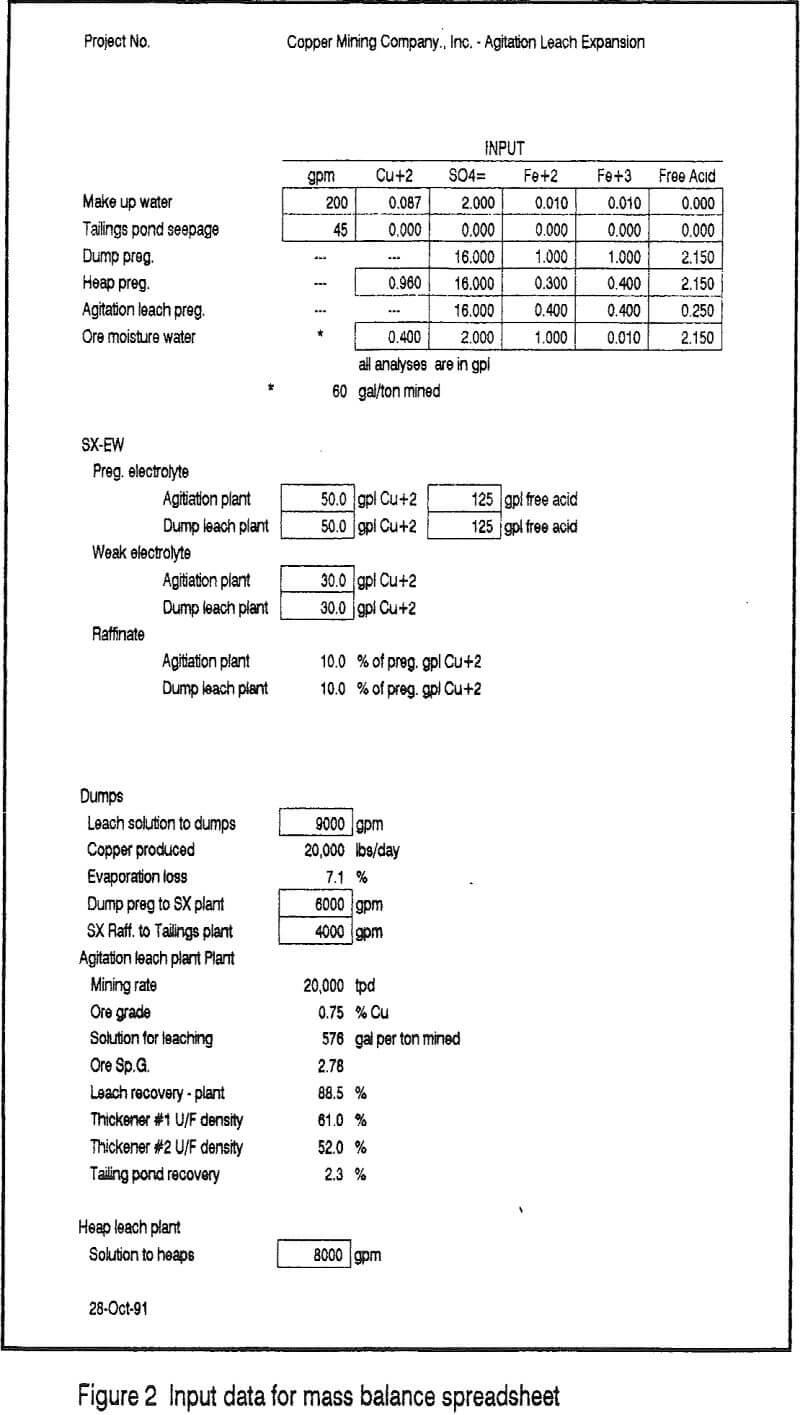

After the flow sheet has be constructed the second step is to establish what, components or parameters are to be included in the mass balance. These parameters are divided into 2 groups for conveyance: masses and secondary parameters. Secondary parameters are those parameters which are derived from masses.

The second task is that of selecting those parameters which are to be specified as the input data. This is the most difficult task in solving the mass balance. It is possible to theoretically determine the number of parameters which need to be specified as “inputs”, however, the choice of which parameters of which streams are specified is not completely a free choice. It is difficult to list rules for the selection of these variables.

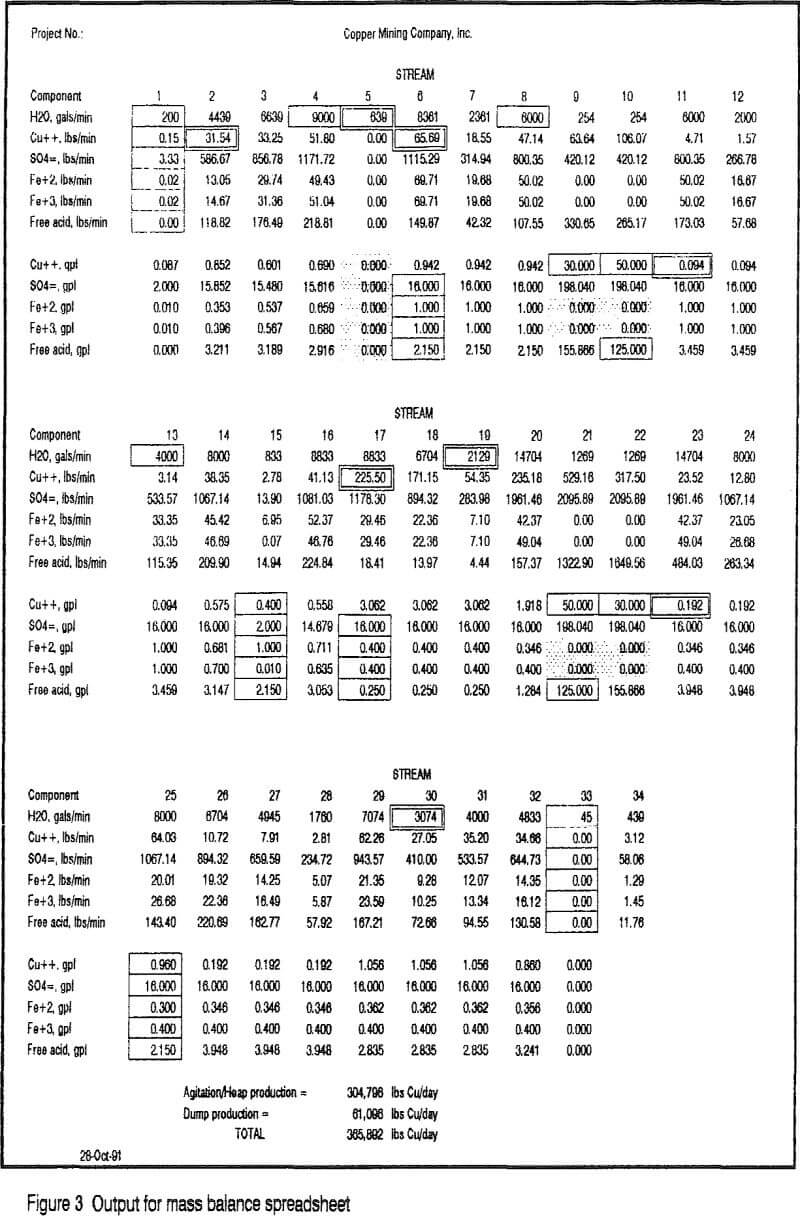

The spreadsheet program could also be used as a steady state process simulator if one of input parameters, for example the copper generated by the agitation leach, is given as a function of the operating conditions such as iron concentration or flow rate. The use of the program as a simulator can be extended by replacing any input by an equation which allows that input to be calculated from other parameters. This in effect adds one more variable to the system but also adds one more equation leaving the number of degrees of freedom unchanged.

Once the input parameters have been selected the spreadsheet in ready to be constructed. The design of the spread sheet is very much a matter of personnel choice but some general rules will simplify the task. First, the spreadsheet should be divided into 3 parts: one for the input data, the second for the calculations and the third part for the output of the calculations. The input section consists of several columns: one column for the name of the stream and a column for each parameter of that stream to be specified by an input. It is sometimes advantageous to have a separate forth section in the spreadsheet to be used to create a report listing the input data.

Initially, equations for the masses in each stream are entered. Stream parameters which depend on the masses, such as volumes, pulp densities and concentration values, can be left until last. However, some of the input data maybe these secondary parameters and this will require the equation of a mass in a stream being dependent on a secondary parameter of the stream. Any value in the input cells or other calculation cells, be they masses or secondary parameters, are legitimate values to be used in any calculation’s cell equation.