Table of Contents

The Kipushi deposit, where the Prince Leopold Mine has been installed belongs to Union Miniere du Haut-Katanga and is located in the Belgian Congo, 20 miles SW of Elisabethville, at the vicinity of the Northern Rodhesian Border.

How does germanium occur

Differentiation of renierite from regular bornite on a freshly cleaved surface is uneasy, but after a few hours of exposure to the air, the bornite turns pink, blue and finally violet, where as the renierite remains unaltered. In the long run renierite eventually shows a brass, brownish shade which cannot be mistaken for the color of bornite.

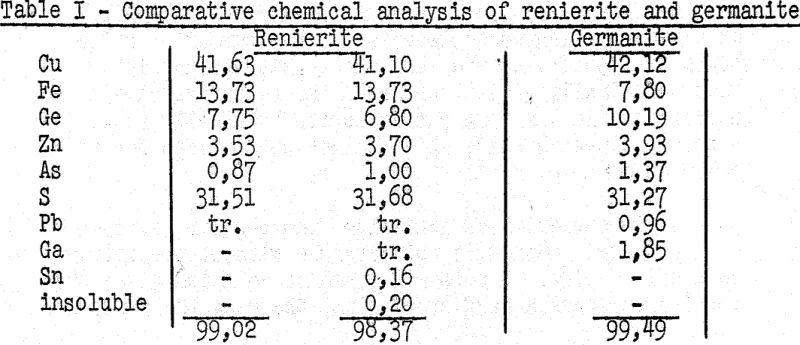

Renierite obeys a complex chemical formula, where positively charged ions are in excess. Composition of germanite differs from that of renierite by a lower ion and higher germanium content.

Magnetic properties of renierite

One of the properties that has long been known about the Kipushi “orange bornite” in the possibility of influencing a compass needle by bringing it near a relatively massive sample of this mineral. Grains of renierite, on the other hand, ground to a few tenths of a millimeter, react more or less to the presence of a permanent magnet some of them are but slightly disturbed, whereas other flock together according to the power lines of the magnetic field.

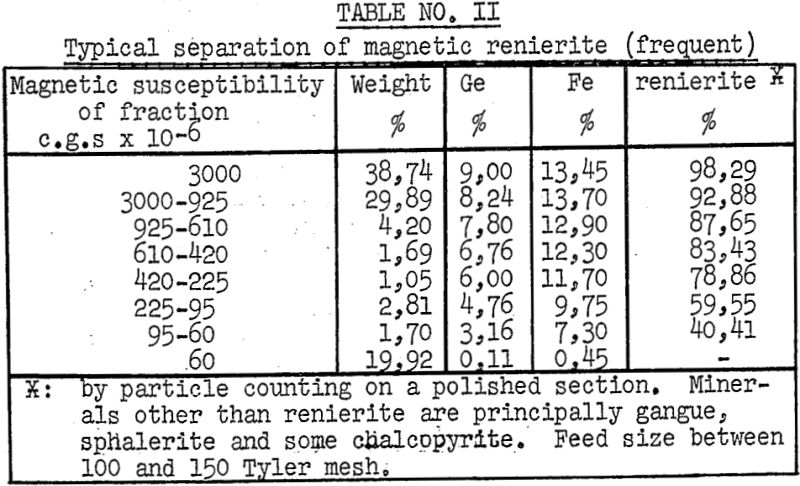

The magnetic susceptibility of renierite shows important variations, which are not related to its chemical composition. Most of the time, renierite bears the characteristics of ferromagnetism. A less common variety of renierite, however, has been identified which does not show any sign of magnetism when treated as a massive sample.

Flotation of renierite

The concentrator of the Prince Leopold Mine has several flotation circuits, fitted to the type of ore which is fed to it: concentration of copper, alone, of zinc alone and differential flotation of copper and zinc.

Renierite is found in the differential flotation feed. This ore contains large quantities of sphalerite, chalcopyrite, bornite (either Cu5 Fe S4 or Cu3 Fe S3) and smaller quantities of renierite, galena, tennantite, chalcocite, pyrite, etc.

The feed of the magnetic separator is the concentrate skimmed from the first cells of the primary copper flotation machines.

It appears from the results that a selective concentration of renierite is quite feasible and that no foreign mineral interferes owing to its magnetic properties. However, such a clear cut separation has never been obtained practically, because of the mechanical difficulties which have been encountered.

Wet magnetic separator on laboratory scale

The slurry flows by gravity through a piling of cylindrical “bee-nests”, which are subjected to a magnetic field. The strength of the field evidently varies throughout the piling and its mean value along the interstices is of the order of 1000 Gauss. The operation is obviously a batch process.

In one of our experiments, five successive filtrations, where performed, using the tailing of previous filtration as feed for the next. The germanium content of the first three concentrates were respectively 1,510% 0,620% and 0,390%. Recovery at this stage totaled 41,0% of Ge of the feed which assayed 0,059% Ge. The fourth and fifth filtrations yielded concentrates of 0,310 and 0,148% Ge, and a partial recovery of 8,8%. The final tailing still contained 0,032% Ge. The weight of the concentrate delivered by each filtration remained practically constant.

Upon completion of the laboratory experiments, the decision was made to install a more powerful ferro-filter at the Kipushi concentrator. The unit selected was a type 461, taking 16a under 110 V.

The purpose of the project was no immediate germanium production, but rather a control of the operation of a plant size unit.

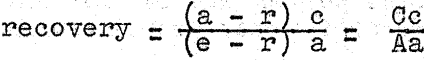

Recovery of above operation was calculated by well-known formula’s:

with a = % Ge of feed

c = % Ge of concentrate

r = % Ge of tailing

A = weight of feed

C = weight of concentrate

Following conclusions could be made from twenty test runs.

If the germanium content of the feed is lower than 0.05% Ge, the grade of the tailing will not vary whether a run lasts 280 or 320 seconds.

Design and operation of industrial installation

The data gathered during above mentioned experiments lead us to design the industrial installation according to following lines:

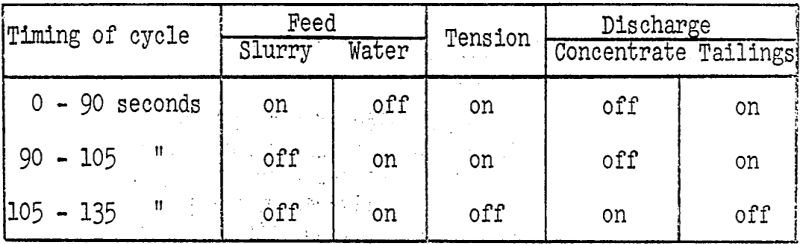

One cycle lasts 135 seconds and includes three steps.

Actually a time lack of 5 or 10 seconds exists between the moment where the slurry is turned off and the water turned on, in order to allow residual slurry to leave the filter. This provision bears no difficulty.

One filter has a unit capacity of 5,5 m³/Hour of slurry. Nine filters have been installed; they ensure a flexible treatment of the plant’s production.

We have grouped the filters three by three. They are mounted at the tops of an equilateral triangle on a platform revolving at a speed of one turn in 135 sec.

The feeding comprises two volumes of slurry and one volume of water which are distributed at the three corners of another fixed equilateral triangle.

Filtration products drop into a fixed circular receiver, divided into a first 105/135 x 360° = 280° sector to collect the tailings and a second 30/135 x 360° = 80° sector to recover the germanium concentrates.