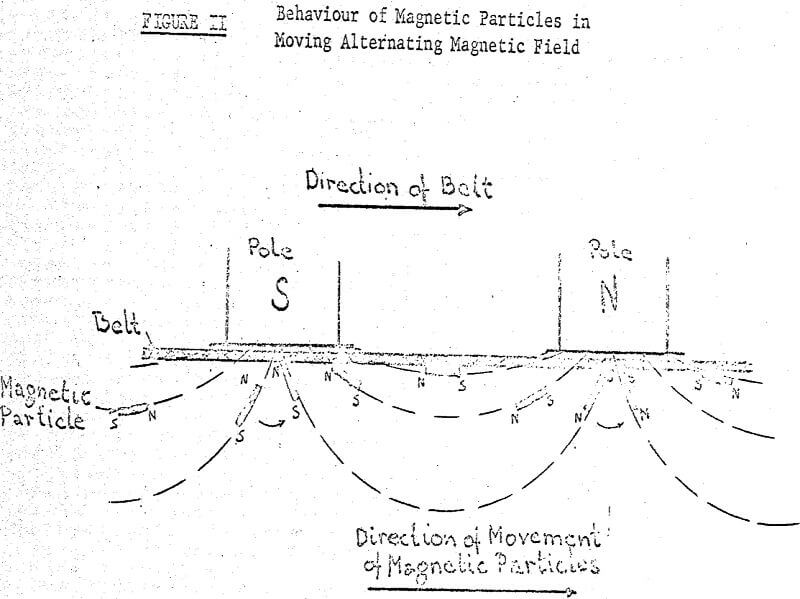

Over a considerable period of time great interest has been shown in selective dry concentration of fine ferromagnetic particles, although it is only recently that new permanent magnetic materials have been made available to permit building of such permanent magnetic separators.

It is well known that the conventional drum separator does not efficiently separate fine materials. The centrifugal force on any drum acts in accordance with the particle size and gravity, which may be at varying magnitude opposite to the magnetic force, especially when the material is not closely sized.

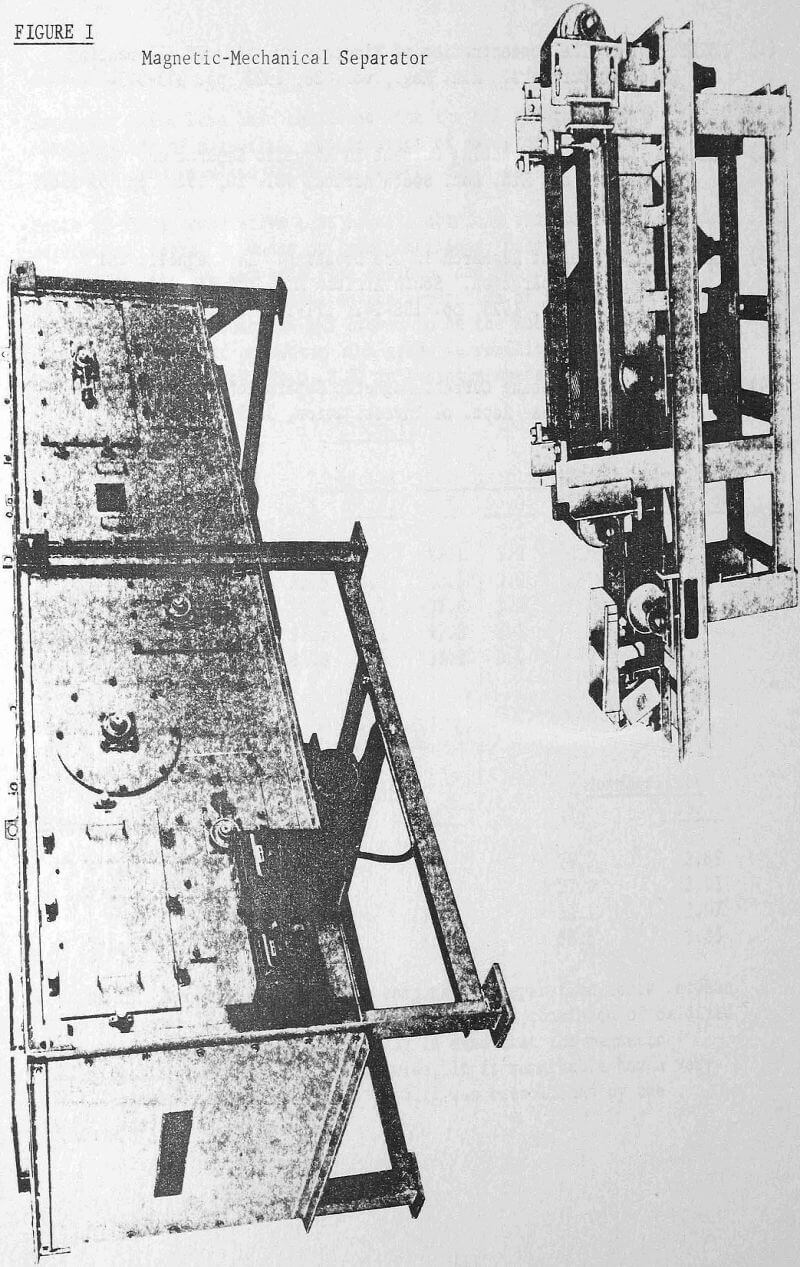

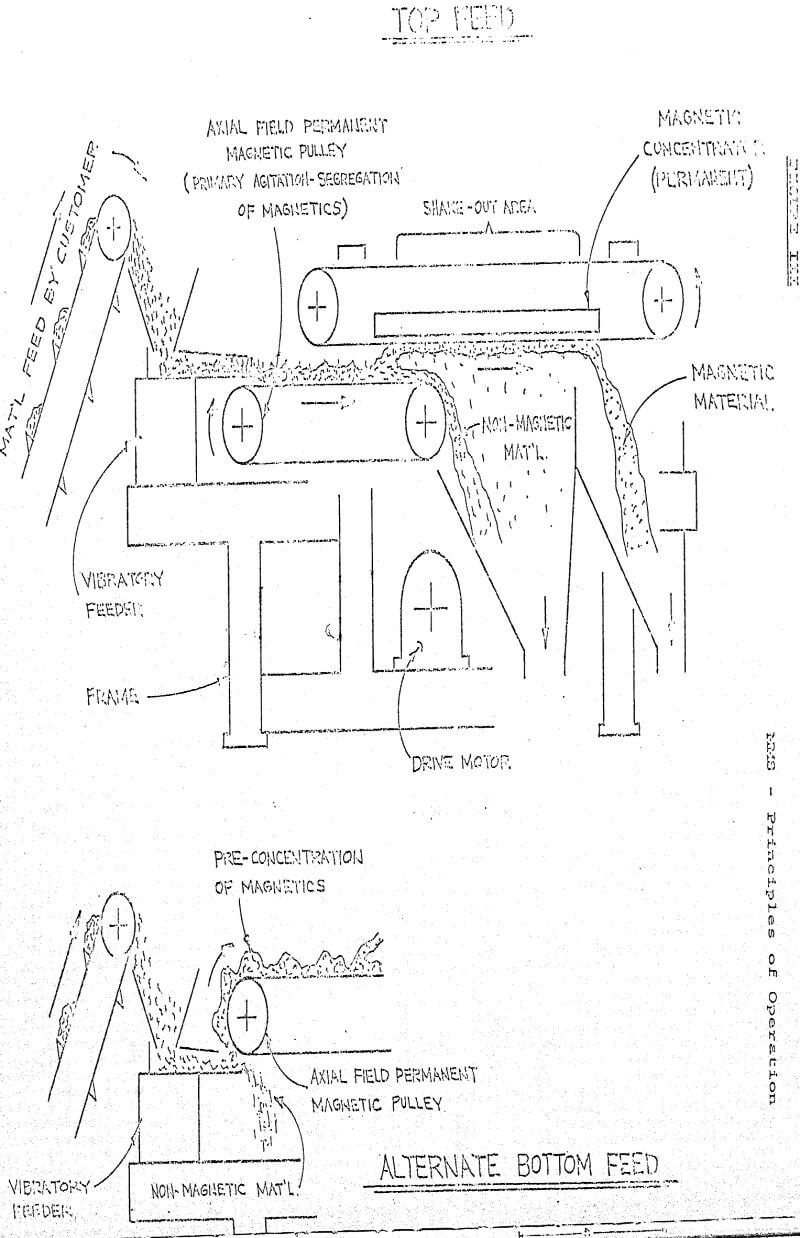

The Magnetic-Mechanical Separator (MMS) is designed for the concentration of fine, unsized magnetic materials where the percentage composition of magnetics to nonmagnetics, or the nature and texture of the materials, is such that its unique agitation and shake-out action with no centrifugal force provides greater efficiency than is obtainable by conventional magnetic separation equipment.

This machine consists of a complete double belt conveyor unit with a premagnetizing Axial Pole Agitating Pulley at the feeding end of the lower conveyor belt and a special agitating concentrator magnet above the lower belt of the upper conveyor.

The cost of the MMS unit on a ton per hour basis is lower than that of a wet magnetic drum, and also the cost of auxiliary equipment is much lower while its selectivity is at least as high.

The MMS has been successfully field proven in numerous installations in the United States and abroad on products which could not be efficiently separated by conventional dry magnetic separators.

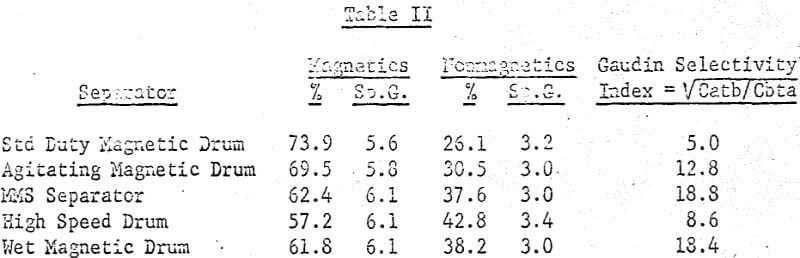

- The MMS dry separator provides near perfect efficiency in applications dealing with fine unsized magnetic, cohesive, porous materials. Further, it is shown in Table V that this separator can produce high grade magnetic concentrate and nonmagnetic concentrate in a single operation.

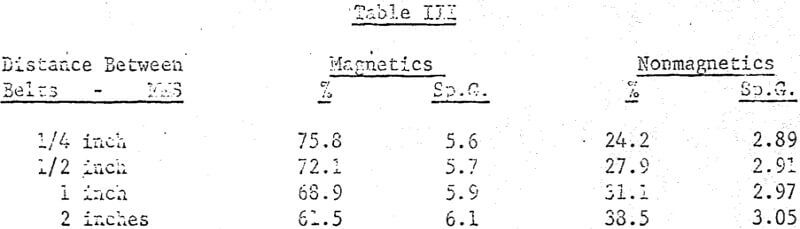

- The MMS separator is a high capacity unit capable of handling minus ½-inch material at a feeding rate up to 1.0 ton per hour per inch of magnetic concentrator width.

- The MMS machine is an automatic magnetic separator requiring minimum supervision and maintenance. A unit in operation at Simonds Abrasive Company since 1961 has had no maintenance problems.

- The separator is a flexible machine with a wide range of optional features; consequently, it is easily adaptable for many applications.

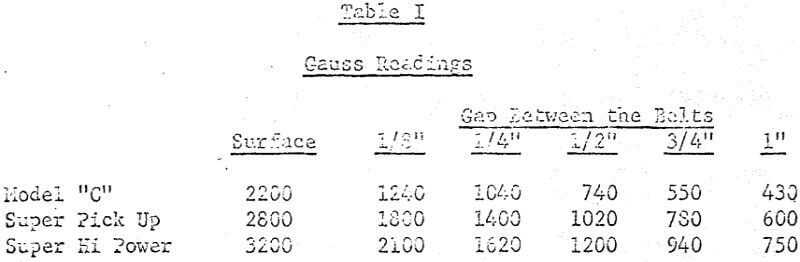

- Powerful permanent magnets are used in the construction of this unit, which has a range of 2200 to 3200 gauss intensity on the surface, with a high gradient to provide maximum removal of the magnetic product.

As the material passes under the magnetic concentrator conveyor, the nonmagnetic particles continue on their way on the lower belt to be discharged from the lower conveyor into a nonmagnetic material discharge hopper. The magnetic particles, however, together with any adhering or entrapped nonmagnetics, are attracted to the upper belt by the magnetic concentrator.