Table of Contents

Investigation of the methods of analyses for magnetite and ilmenite in the Otanmaki iron-titanium ore and respective mill products has resulted in certain improvements in the methods conventionally employed. The outcome of the investigations is summarized as follows:

- Development of a diamond-drill core analyser for the determination of magnetic susceptibility of drill cores containing magnetic minerals.

- Development of a magnetite-ilmenite analyser for pulverized products.

- Development of a potentiometric method of chemical analysis for the determination of iron, vanadium, and titanium in succeeding steps from one test sample.

- Proposal for a continuous and automatic magnetite assay method.

Diamond-Drill Core Analyser

The conventional method of assaying diamond-drill cores consists of splitting the cores, pulverizing them and running chemical analyses on representative samples. The physical properties of magnetic minerals, however, offer an entirely different approach to obtain similar final result by the measurement of respective magnetic susceptibilities in a properly designed instrument.

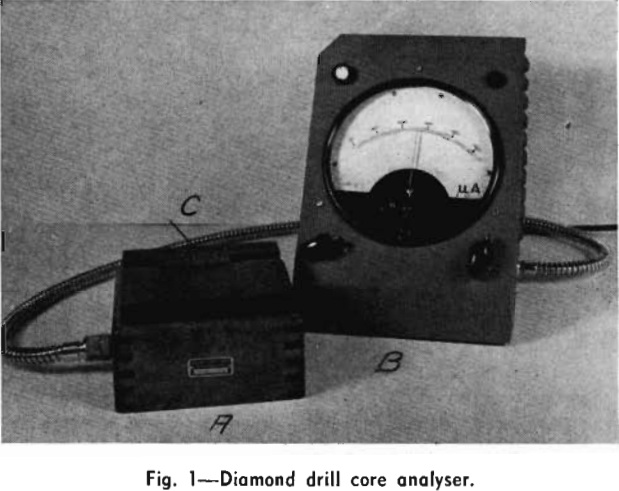

Essentially it consists of a magnetic unit, A, and of a meter unit, B. On top of A is a slot where a piece of diamond-drill core C is visible. The magnitude of disturbance in the original magnetic field caused by the magnetic minerals in the drill core can be observed from the microammeter. This reading is a function of the combined susceptibilities of all magnetic grains in the magnetic field.

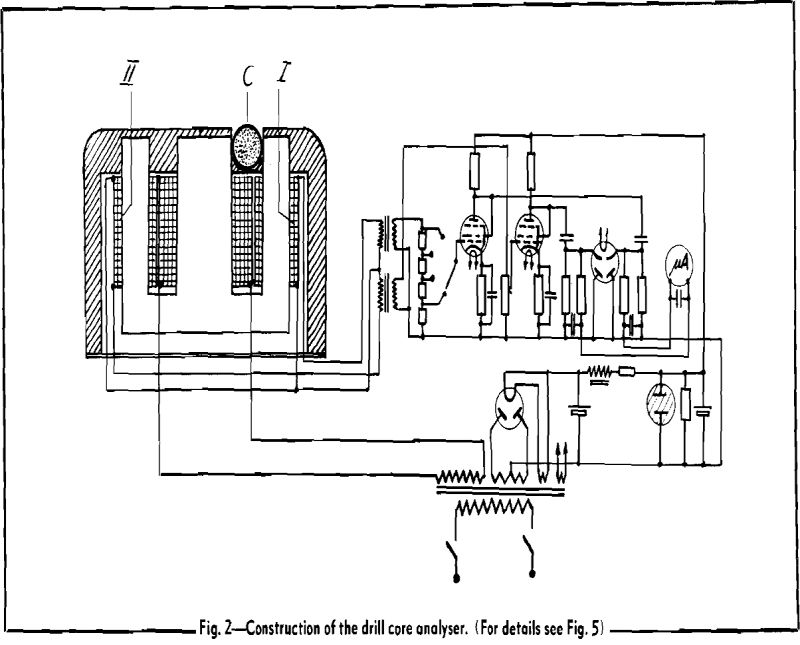

The voltage difference is measured with a Brentano tube voltmeter. If extreme sensitiveness is desired, the established symmetry of the magnetic circuit does not allow reduction of the O-voltage difference far enough. Therefore a compensatory voltage of a correct phase taken from the terminals

of one of the secondary coils is connected to the grid of one tube of the tube voltmeter. With this arrangement it has been possible to include four scales of sensitiveness in sequence of 1:4:16:64. The least sensitive scale is used for cores containing magnetite. A core 22 mm in diam of relatively pure magnetite causes a reading of about 80 pct of the available scale. The lowest value of susceptibility that can be observed with the most sensitive scale is of the order of 0.001.

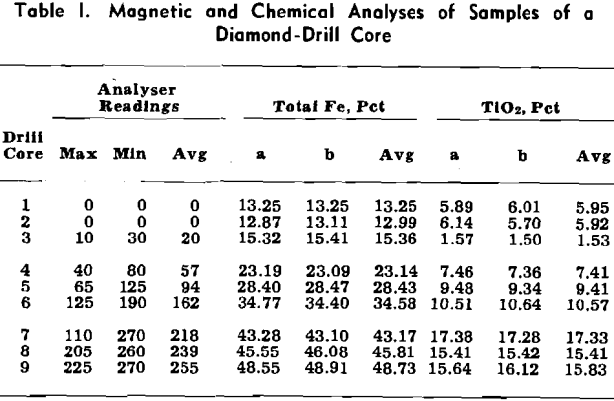

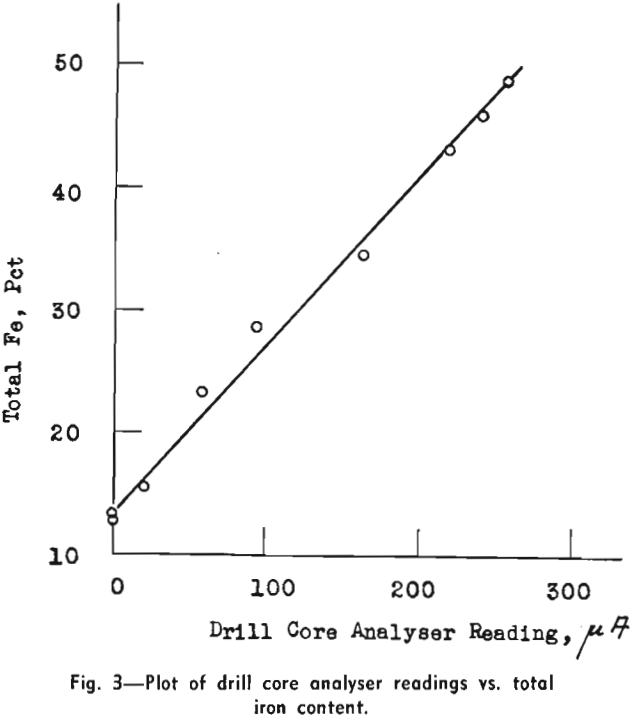

The analyser offers a rapid and inexpensive method for preliminary analysis of drill cores carrying magnetic minerals. It obviously is best suited for ores where magnetite is the only iron-bearing mineral. No great accuracy can be claimed mainly because of unavoidable variations in core diameter. Since the diamond-drill core itself, even with the best possible recovery, represents only an approximation of the respective rock; and the splitted halves are an approximation of the cores recovered; the drill-core analyser method, which takes into account the entire core available (if readings are taken in close enough steps) probably represents the same order of accuracy as can be claimed for the conventions method. In field use, the analyser can reduce materially the number of chemical assays required, but it is not expected to replace them altogether.

A pulped sample is introduced through the funnel of a slowly revolving distributor into a vertical glass tube filled with water. The magnetite fraction of descending particles is held against tube walls by an inhomogeneous magnetic field produced by an ac excited magnet resembling in construction a “magnetic lens.” The strength of the field holds all particles of magnetite but no ilmenite. The tube is surrounded also by a secondary coil in which the retained magnetite induces a voltage the value of which is a function of the amount of magnetite present. This voltage is indicated in the meter unit by a tube voltmeter.

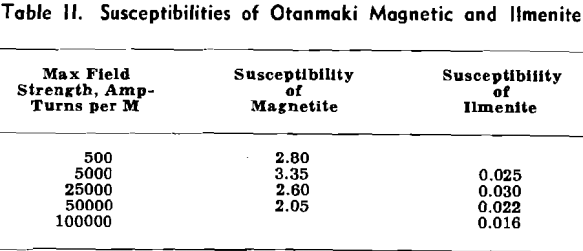

The ilmenite fraction is held by a strong ac magnetic field of the type used in the drill-core analyser described above. The ilmenite retained causes a change in the flux of the magnetic field resulting in a change in the voltage difference of secondary coils.

A correct determination of ilmenite simultaneously with magnetite requires that all ilmenite particles report in the ilmenite circuit. This condition hardly can be fulfilled in analysing magnetite concentrates containing small amounts of ilmenite. The interlocking of even a small fraction of the ilmenite within the large bulk of magnetite is enough to cause serious errors in the amount of ilmenite reporting in the lower field.

Continuous Magnetite Assay

A fully automatic and continuous plant assay control system is the dream of many a millman. Numerous attempts have been made to solve the problem, but as far as the authors know none of them has been successful.

The magnetic instruments described in this paper seem to offer a marked step forward toward continuity, instantaneous evaluation, and exact recording of product assays. The following apparatus seems to be essential for the determination of magnetite:

- Equipment to form continuous and representative sample bar of the pulverized product to be analysed. This bar corresponds to a diamond-drill core in the preceding discussion.

- Magnetic unit through which the sample bar moves. In principle this unit is the same as the one used for diamond-drill core analyser.

- Measuring and recording unit for the evaluation of the magnetic effect caused by the sample bar. The measuring unit would correspond to the respective unit of the drill core analyser.