In the world of mining and milling the “electrical term” LSSM stands for “Low Speed Synchronous Motor” and usually means a mill where the motor rated speed is in the range of 10 RPM, the same speed as the mill turns. A high speed motor can run at 900 RPM and uses a gearbox to turn down the speed. A medium speed motor runs in the range of 100 RPM and uses the gear ratio of the pinion and mill ring-gear to step down the speed.

GMD Gearless mills are always variable speed. The incoming electrical supply voltage has a frequency of 50-60 Hz (3000 – 3600 RPM) that must be stepped down to control the input frequency of the low speed motor (10 RPM). The only way that is done on a modern mill is with a cycloconverter which is also a variable speed control mechanism.

A variable speed mill driven by a LSSM motor would have a cycloconverter (variable speed drive) ahead of it in the electrical network.

Also note that a motor with a reducer is much less efficient that the LSSM that is directly driving the mill.

The video below helps explain.

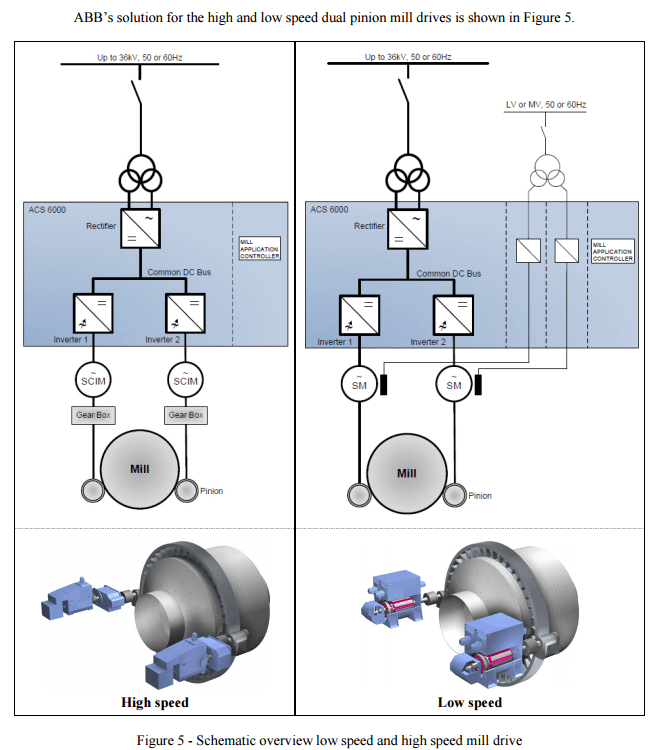

Overview on the grinding mills and their dual pinion mill drives