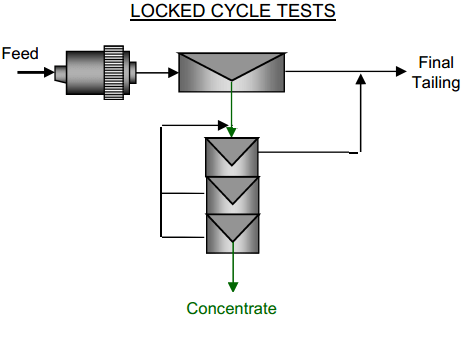

Here are rough instructions to perform a sequential flotation locked cycle test procedure to assess the overall metallurgy of an ore sample expected to produce only 1 concentrate product. The procedures described in this Method are to be used as a guideline only. The final test conditions and flowsheet are actually determined from in-house experimental investigations.

Here are rough instructions to perform a sequential flotation locked cycle test procedure to assess the overall metallurgy of an ore sample expected to produce only 1 concentrate product. The procedures described in this Method are to be used as a guideline only. The final test conditions and flowsheet are actually determined from in-house experimental investigations.

Preparation Prior to Test:

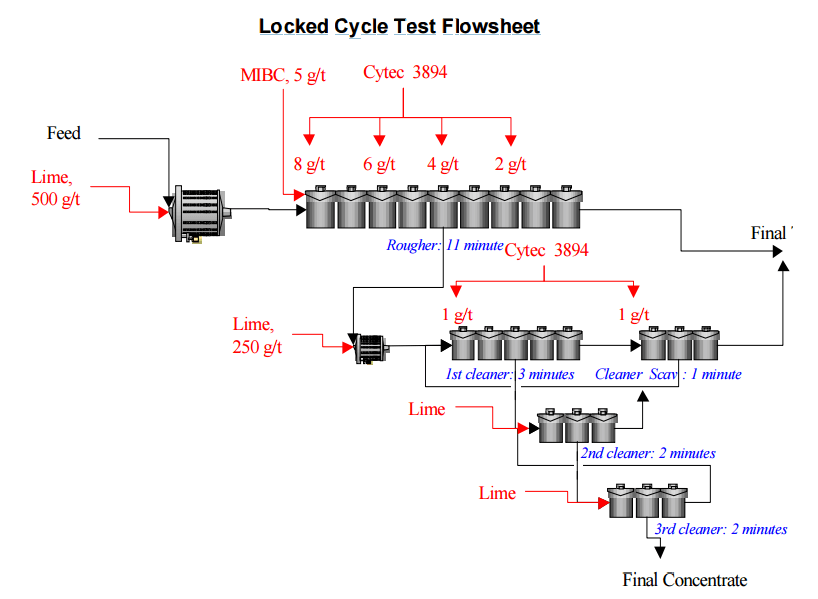

Determine the type, strength and volume of reagents required to complete the test procedure.

Calibrate the pH meter and Eh meter, if required.

A) Primary Grinding Procedure:

Proceed with cleaning the mill and sample grinding

Hold the sample for further testing. Do not place the sample in the oven to dry.

B) Cycle #1 Rougher Flotation Process and Regrinding (if required):

- Transfer pulp from grinding into an appropriate flotation cell and place on a Denver flotation machine completely submerging the impeller into the pulp.

- Add sufficient water to the cell so that the pulp level is approximately cm below the lip of the cell.

- Turn on the machine and adjust the impeller speed to 900 rpm and measure pulp pH and Eh if required.

- Open air valve and aerate the pulp for one minute.

- Add sufficient pH modifiers, collectors, promoters and frothers to activate and collect the appropriate minerals.

- Condition the reagent-rich pulp without aeration for two minutes.

- Add sufficient frother and air to maintain a stable froth and recover a flotation rougher concentrate by scraping off the froth into an adequate container. Throughout this stage continue to add frother and collector as required to recover the valuable mineral from the host rock. (Use information derived from the rate of flotation test procedure to help guide this phase of the test

C) Cycle 1 Cleaner Flotation:

- Transfer the rougher concentrate or regrind discharge pulp into an appropriate flotation cell and place on a Denver flotation machine completely submerging the impeller into the pulp.

- Add sufficient water to elevate the pulp level to 2-3 cm below the cell lip.

- Condition the pulp and add sufficient pH modifier, collector and frother to recover the valuable minerals.

- Turn on the air and scrape off the first cleaner concentrate into an appropriate container until the froth appears devoid of mineralization.

- Condition the first cleaner tail with reagents as required and float off a cleaner scavenger concentrate sample.

- Filter the cleaner scavenger concentrate and tailing samples, identify and set aside.

- Return the first cleaner concentrate pulp to the flotation cell and machine and float off a second cleaner concentrate into an appropriate container until the froth appears devoid of mineralization.

- Filter the cleaner tail, identify and set it aside.

- Repeat cleaner steps 8 and 9 until the desired final concentrate is achieved. (Use information derived from the cleaner test procedure to help determine the number of cleaning stages required.)

- All Cycle 1 filtered products are identified and set aside.

D) Cycle II Rougher and Cleaner Flotation:

- Repeats steps A, B and C on a fresh ore sample.

- Add the filtered cleaner scavenger concentrate and all of the cleaner tail samples from Cycle I to the cleaner feed pulp for Cycle II.

- Repeat steps B#2 to B#7 using the same number of cleaning stages utilized in Cycle I.

E) Cycles III, IV and V:

Repeat steps D#1 to D#3 for cycles III, IV and V.

__

- Record on an appropriate flotation conditions worksheet, the reagents added to the test stages, the pH and, if required, the Eh levels in each stage and the grinding conditions and flotation times of each stage.

- Place the well labelled filtered test products into appropriate pans and dry in an oven set to less than 110 Celsius.

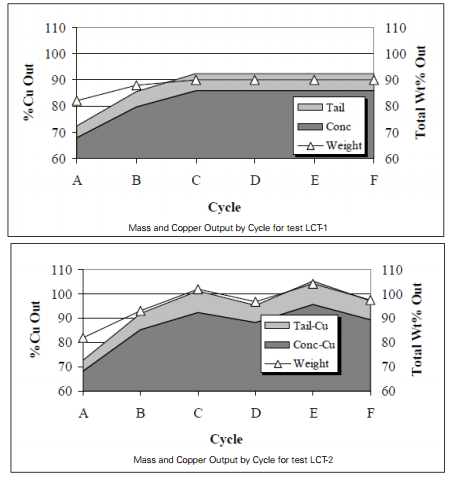

Review Locked Cycle Tests Evaluation to see how your test went.