Table of Contents

The primary purpose of the loading plant is to transfer the finished product from the preparation machines to the railroad car, truck, or barge in which it is to go to market. Secondary purposes of the loading plant are: to prevent excessive degradation of sizes during loading, to reduce segregation as much as possible, and to prevent excessive quantities of very good or off-grade coal from entering any one car.

Degradation in Storage, Loading and Shipment

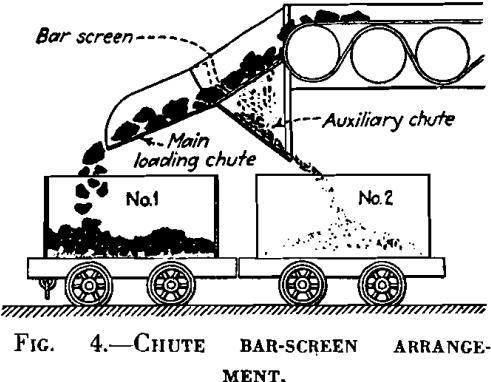

The object in loading is not only to handle the coal without breakage and segregation, but also to produce a well-trimmed load that will ride to its destination without spillage or breakage en route. The small sizes present in a car of prepared coal as received by the purchaser consist of: missed small sizes not screened out in the preparation plant, breakage during loading, and breakage caused by handling en route.

For domestic sizes of anthracite shipped from the Pennsylvania anthracite field to Atlantic coast cities, the dealers loss because of breakage in loading and shipment amounts to from 2 to 5 per cent and for anthracite shipped to Middle West cities, the loss is 8 to 9 per cent. This difference is in part because dealers in the Middle West rescreen their coal more thoroughly than is usual in the East.

One dealer handling Illinois No. 6 coal shipped from southern Illinois mines to Chicago reports an average size loss of 10 per cent when lump coal is unloaded with a fork. This runs as low as 5 per cent for carefully loaded coal and as high as 15 per cent for carelessly loaded coal.

Loading Pockets

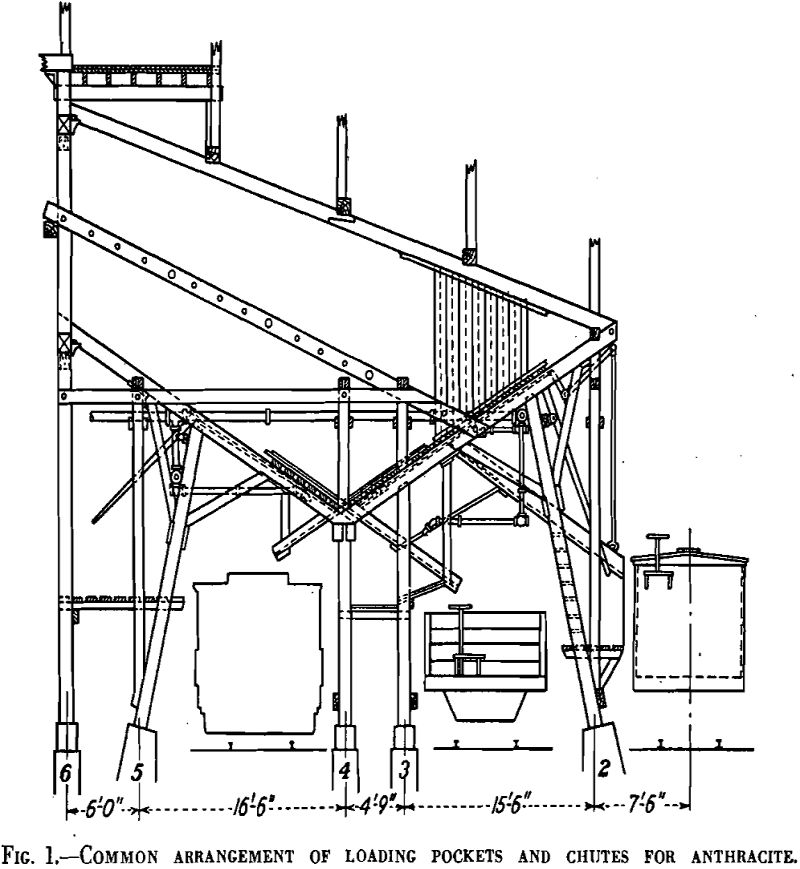

Loading pockets are provided usually for all commercial sizes of coal made in anthracite-preparation plants. Products from the various cleaning units are conveyed to these pockets by chutes or shaking conveyors and lowered into them by telegraphs or special lowering chutes to reduce breakage. These pockets act as storage and draining bunkers. Cars are loaded intermittently as accumulation of the various grades permits.

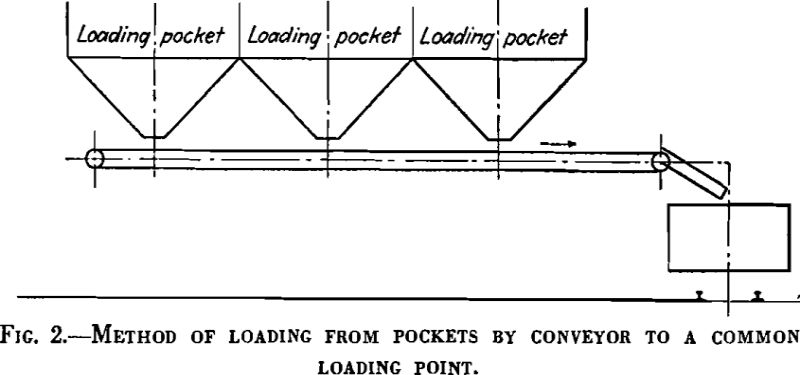

In bituminous practice, the larger prepared sizes—lump, egg, and nut— usually are not stored in pockets but are transferred directly from the tipple to the car, continuously, during the operation of the preparation plant. As a rule, only the screenings and small nut sizes are accumulated in bins for intermittent loading; and very often screenings when shipped without re-screening to produce the small nut sizes, are loaded continuously. Exceptions to this general practice are sometimes necessary where more than one size of coal must be loaded on one track. This may be unavoidable in a preparation plant situated in a narrow valley because of insufficient space for multiple-track loading.

Loading Pockets for Bituminous Coal

At washeries and rescreening plants where the small nut sizes are made, the method of loading usually is similar to the first method described for anthracite practice. Hopper-bottomed steel bins ordinarily are arranged along a common loading track and the various sizes are loaded in rotation.

Loading Devices

The devices used for lowering coal into cars are: loading chutes, loading booms, lowering skips, and box-car loaders. The loading chute is the oldest and most widely used loading device. It is used for all sizes of anthracite and for those grades of bituminous coal in which breakage is not of first importance; for example, slack and run-of-mine coal that is to be crushed before using.

Loading Chutes

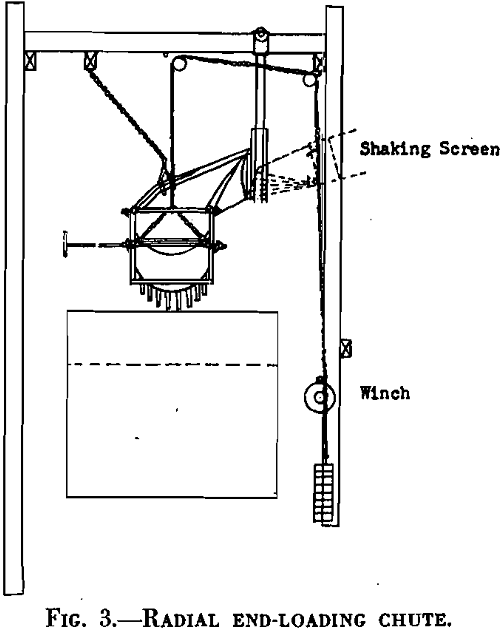

The loading chute is simply a gravity chute used to convey coal from the pocket or the screen to the railroad car. The side-loading chute is placed at a right angle to the loading track, so as to deliver coal at the longitudinal center line of the car but traveling in a direction crosswise of the car.

Adams vertical lowering chutes are used at many breakers in the anthracite region to reduce breakage in transferring coal from loading pockets to rail-road cars. A solid stream of coal is maintained. The vertical part of these chutes is constructed of three sides only, the open fourth side being mounted to face a flat steel plate permanently attached to the breaker structure. These chutes are raised or lowered by an electric hoist. As the level of the coal rises in the car, the chute is raised without stopping the flow of coal, since it is fed continuously to the open back side of the chute regardless of its height.

Loading Booms

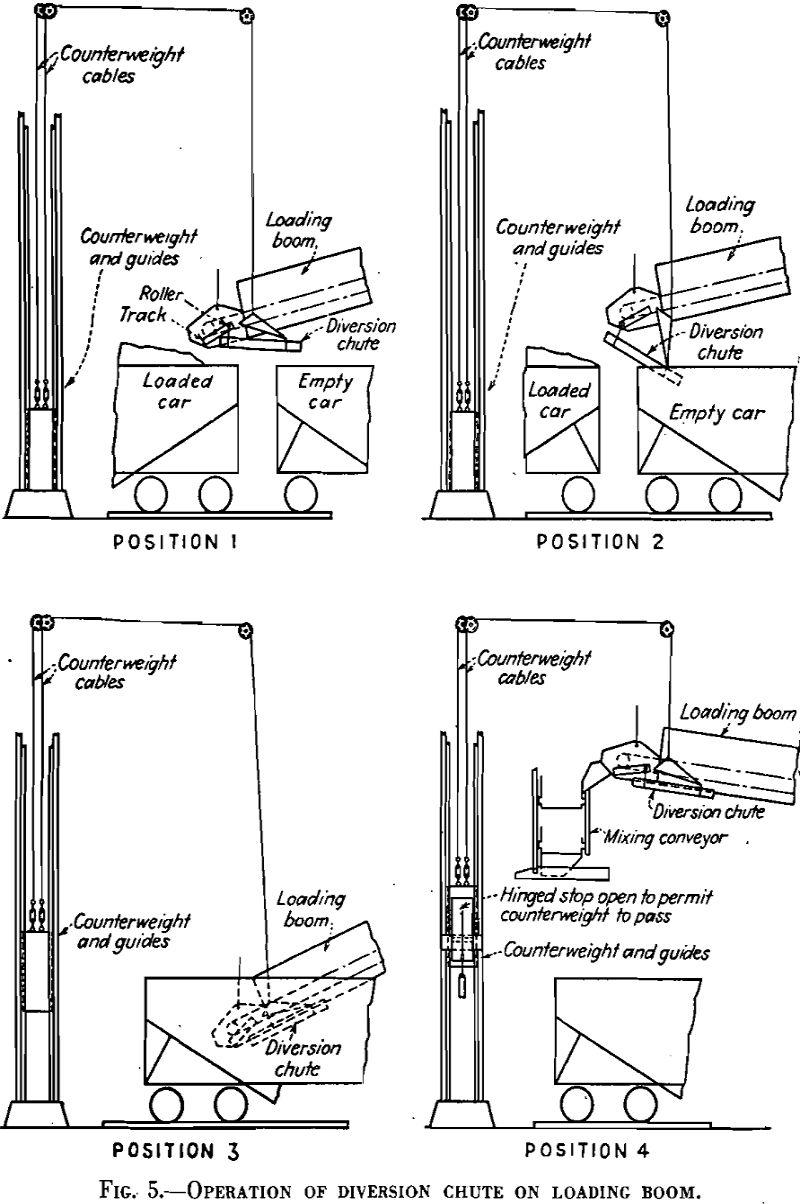

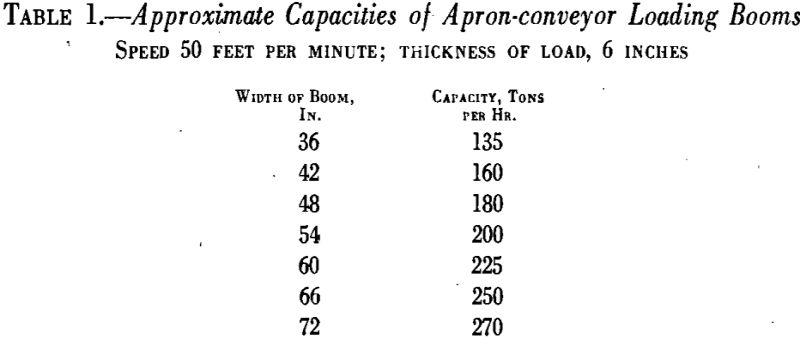

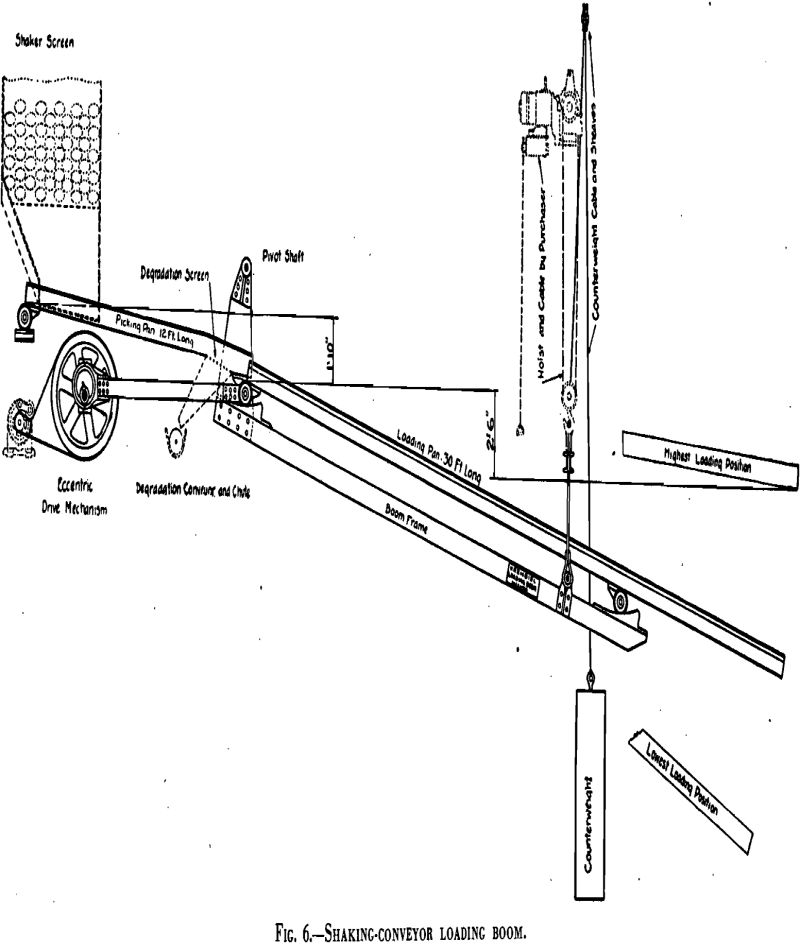

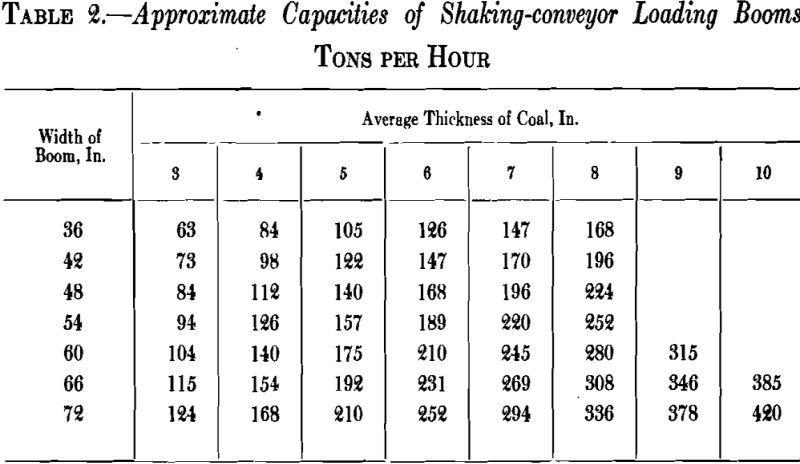

The loading boom is an adjustable conveyor used for lowering coal into cars with little breakage. The boom conveyor has a fixed elevation at the end at which coal is discharged upon it from the tipple screen, or loading pocket. The delivery end of the boom may be raised and lowered by a mechanical hoist. This permits it to be lowered into a car when loading begins, so as to deposit the coal on the bottom of the car without dropping it any great distance. The boom inclination is adjusted during operation to keep the delivery end close to the load and deposit the coal theron with a minimum drop.

Booms are raised by means of overhead electric hoists, operated by a man on the loading platform in the boom house, by an operator in a control tower, or by the car loader and trimmer who rides on a foot board attached to the delivery end of the boom. Booms usually are equipped with 2-ton hoists with a lifting speed of 20 ft. per min. The empty boom generally is balanced by counterweights suspended in guides outside the structure and connected to the boom by a cable. The counterweight is a little less than the dead weight of the boom, so that the empty boom can be lowered into a car by gravity. Where no counterweights are used, the capacity of the hoist usually is 5 tons. In some early installations, hand-operated booms equipped with chain and pulley tackle for raising and lowering the hinged section were used but these have been superseded by the electrically operated type.

Box-car Loading

Many methods are in use for loading coal into box cars, varying from 100 per cent hand loading with shovels to the use of completely mechanized self-propelling loading machines. The principal methods in use may be classified as follows:

- Hand loading of coal delivered to center of car by chute or boom.

- Extensible curved chutes. These are shoved into a side door of the car and then extended toward the end of the car.

- Hand-propelled portable belt conveyors.

- Mechanical box-car loaders with tilting-frame adjustable conveyors.

Hand loading of coal into box cars is a comparatively expensive operation, which as a rule is done only at small operations where local market conditions justify special handling of a very friable or easily weathered coal.

Our Buying Guides that are worth checking out: 8 Best Folding Hand Trucks