Chile is the world’s largest copper producer and as such sets the standard of practice in copper SX/EW design. The authors summarize the liner systems used at many of Chile’s major copper producers – both operating and planned. The evolution in the state of the art is also discussed, considering both economic factors and Chile’s burgeoning environmentalism.

Unique Geo technical Issues

Northern Chile is famous for its nitrate mines, and more recently its solar salt projects. Salt is ubiquitous in Chile’s northern soils, and these salts are soluble in acidic pregnant leach solutions (PLS). Concentrations of acid-soluble salt range from less than 1% to in excess of 30 percent.

All liners leak and when this leakage enters such soils the salts are dissolved. Since the salts are part of the soil matrix, their dissolution triggers settlement, which causes strain in the liner. At some point the strain enlarges the hole, increasing the leakage rate, causing more settlement and increasing the strain in the geomembrane.

Cerro Colorado

Initial ore production and processing will be at the rate of 10,000 tonnes per day (TPD), increasing to 15,000 TPD. The leach cycle will be 210 days.

The pad was constructed by filling the valleys with up to 30 meters of mine overburden and waste rock, placed dry and in lift thicknesses of 5 meters at the bottom decreasing to 2 meters at the top. The fill was monitored to verify that primary settlement was complete prior to installation of the geomembrane. Post-construction settlement was estimated at 0.5 to 1.0% of the fill thickness.

Ivan-Zar

Owned by Minera Rayrock, Ivan-Zar will be a relatively small but high grade heap leach. Reserves total 3 million metric tonnes of oxide ore at 2% copper, and 1.7 million tonnes of mixed ore at 3.5 percent Total pad area will be 266,000 square meters. Ultimate heap heights are 20 meters for the oxide heaps and 12 meters for sulphide and mixed ore. Ivan-Zar should be commissioned in mid 1994.

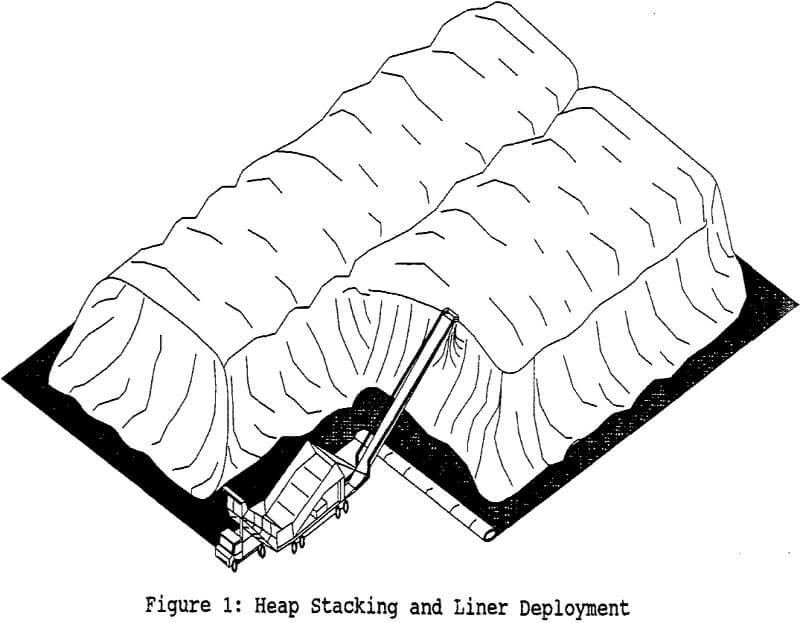

Ore will be crushed to minus 12mm and stacked with conveyor stackers in lifts of 4m for both oxide and mixed ore. The base liner will be advanced continuously as the heap is stacked, with the edge of the liner always between the active face of the heap and the wheels of the stacker.

After each lift of ore is completely leached, a 0.75mm geomembrane will be installed (oxide heaps only) and the next lift placed in the same manner as the first.

Mantoverde

With reserves of 81 million tonnes at 0.83% (heap leach) plus 21 million tonnes (dump leach at run-of-mine) at 0.45% and a 15 year life, Mantoverde will produce an average of 42,000 tonnes of copper per year. Ore processing will average 15,000 TPD. The owner is Enpresa Minera Montos Blancos.

The ultimate leach pad will exceed 3 million square meters. At the ultimate heap height of 30 meters, the heap capacity is 81 million tonnes.

The base liner system will consist of prepared nature soils for bedding, a 0.75mm PVC geomembrane, and perforated drainage pipes over the geomembrane.

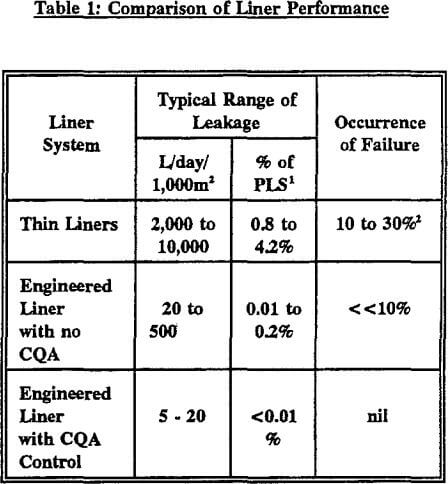

Estimates of Leakage Rates & Liner Performance

The purpose of a liner is to restrict leakage to acceptable levels. Therefore, the best way to judge liner performance is by the leakage rates. When environmental protection is the goal then the allowable leakage rates are generally very low. But in the case of many Chilean mines the nature of the sites makes environmental protection a secondary consideration; the primary purpose becomes one of economics. The optimum liner system is one which has the lowest net present value of the liner cost plus the value of the lost solution, including reasonable contingencies for failures and allowances for environmental risk.