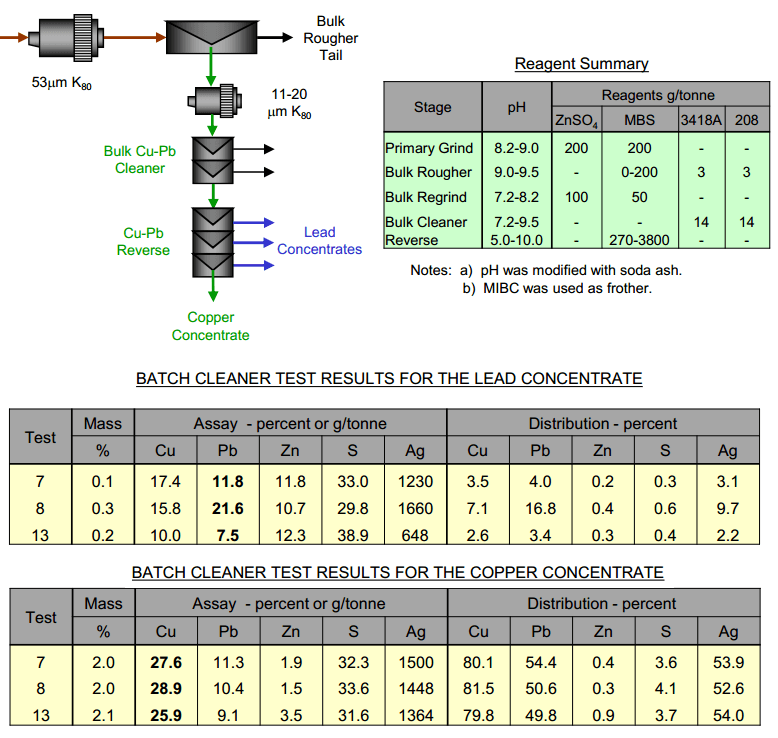

A series of tests were completed with bulk copper and lead flotation with the depression of lead and flotation of copper. This alternative utilized

MBS as the primary depressant in both the bulk and reverse circuits.

The challenge of this scheme is that the lead concentrate will be the tailings of the reverse circuit and will likely always be of poor quality. It

would require very clean bulk concentrates, with very little pyrite or sphalerite.

The lead concentrate was indeed very poor quality. The concentrate grade ranged from 7.5 to 21.6 percent lead at very low lead recovery from the feed. The concentrate was heavily contaminated with copper, zinc and sulphur (pyrite).

The copper metallurgical performance was better, on average, 81 percent of the copper in the feed was recovered in the concentrate grading 28

percent copper. However, the concentrate contained nearly 11 percent lead with lead recoveries to the copper concentrate of about 52 percent.

The limited testing indicated that this reagent scheme was less effective in the reverse than the cyanide scheme. If the ratio of lead to copper is

expected to increase in future ores, this scheme might be more effective.