Table of Contents

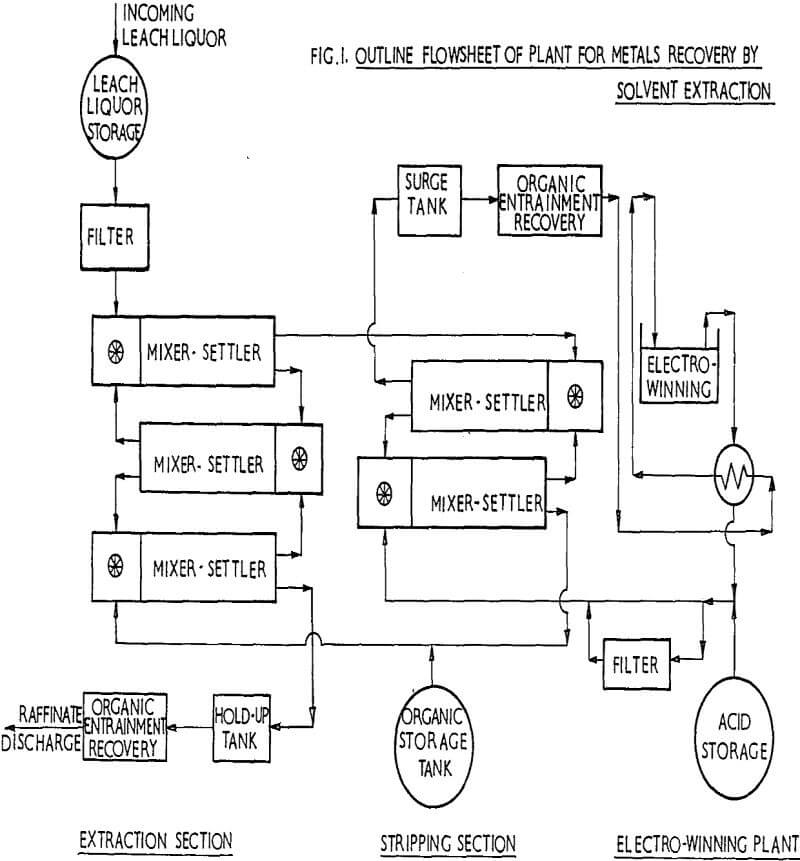

This paper outlines the physical and mechanical factors which must be taken into account when designing mixer-settler systems for large scale solvent extraction plants. The performance of the equipment will also be dependent upon the chemistry of the system, including the kinetics and thermodynamics of the ion exchange reaction itself, the effect of impurities flocculants, surfactants, temperature, etc., but these will not be dealt with here.

Much of the laboratory work has been carried out using copper containing solutions and either LIX 64 or LIX 64 N as the solvent dissolved in various grades of kerosene. For simplicity, all the graphs and tables of results which are presented and discussed here will refer to the LIX-copper system, although the conclusions will in many cases be generally applicable to other systems also. The LIX-copper process is now sufficiently well known to obviate the need for a full description.

Factors Affecting the Cost and Performance of a Mixer-Settler

In order to arrive at the most economic design of a mixer-settler system for a given application it is necessary to consider all those factors which affect both the capital and operating costs of the system.

The factors having a significant effect on the capital cost are:

- Number of stages of Mixer-Settlers

- Settler Area per Stage

- Mixer Volume per Stage

- Solvent Inventory

- Solvent Recovery Equipment

- Ancillary equipment including Pumps, Pipework, Instrumentation, etc.

Similarly the operating cost is made up of the following:

- Cost of solvent loss

- Cost of acid loss

- Cost of power to mixing

- Cost of power to pumping

- Operating labour cost

The specific settler flow determines the area of the settler required in order to obtain a substantially complete separation of the mixed phases for any given flowrate. However, the two phases leaving a settler are in practice never completely separated and each phase contains trace Quantities of the other phase finely dispersed throughout its bulk. These criteria upon which settler performance may be assessed are largely dependent upon the values of the same set of independent variables that affect the mass transfer performance of the mixer, the fundamental links being the droplet size, viscosity and interfacial tension of the mixed phases passing from the mixer into the settler.

Mixer Configuration

The configuration of the mixer includes not only the design and location of the impeller in the mixing chamber, but it also includes the shape of the mixing chamber, the location of the inlet and outlet, and the design and location of baffles.

All these should be viewed together as constituting the mixing environment since they all profoundly affect the velocities and flow patterns developed in the mixer and hence the droplet size distribution produced. For the same reason it is necessary to maintain geometric similarity between the laboratory and the ultimate plant scale if reliable scale-up of mixer performance is to be achieved.

Two particular disadvantages of the design shown are worthy of mention in addition to the limitation in the size of mixer that it is practical to operate. Firstly, there is no longer full-width flow from the mixer into the settler and there is consequently a tendency for mal-distribution of flow across the settler leading to inefficient settling. This may be partially overcome by the installation of a suitable baffle at the inlet to the settler which distributes the mixed phases across the full width of the settler. More will be mentioned of this in the section on settler design.

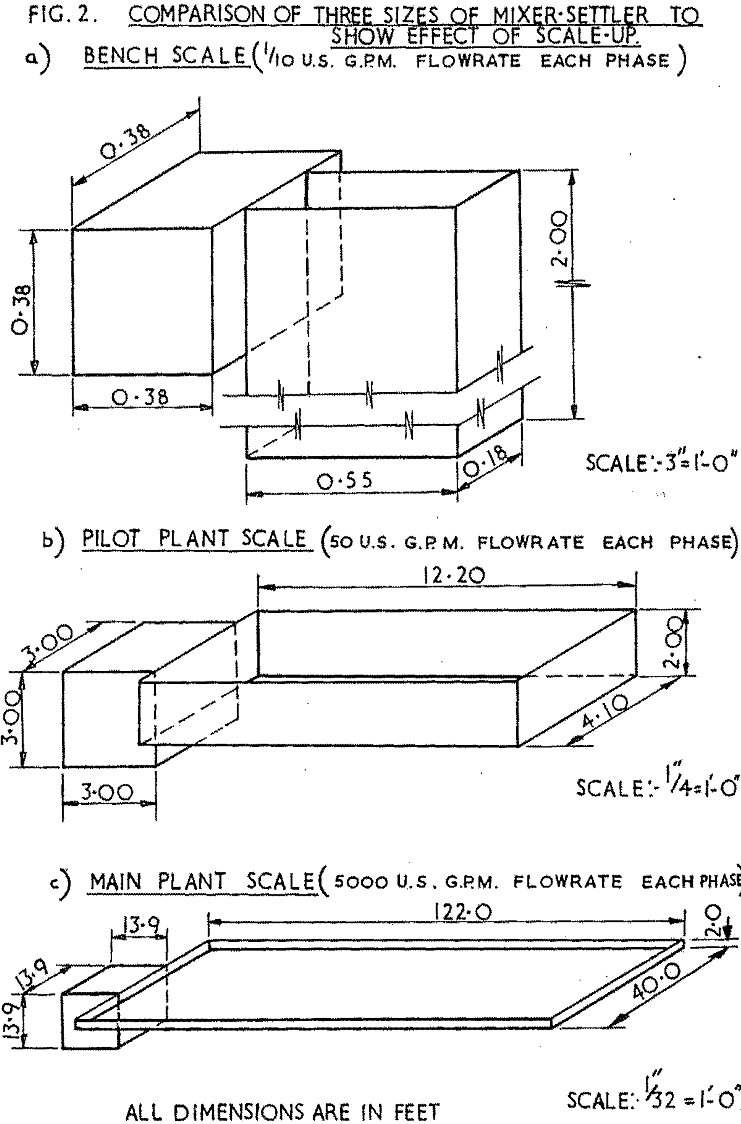

Secondly, the adherence to the geometric scale-up criterion results in the mixing chamber gradually becoming deeper until at a total throughput of 10,000 US gpm it has a depth of 13.9 ft. Since the organic phase in the weir of the previous settler has a specific gravity of, say, 0.8 and the mixed phases in the mixing chamber have a mean s.g. of about 0.9, the static head to be overcome in order to pump the organic phase into the mixing chamber increases with increasing mixer depth.

Each separated phase passing from one stage to the next invariably contains a quantity, generally small, of the other phase dispersed throughout it. The quantity of entrainment of one phase in the other will depend on a number of factors, but the size of the entrained droplets can be greatly reduced by the high degree of shear which occurs during passage through a pump and this may lead to subsequent settling difficulties and high levels of solvent loss and acid carryover.

The problem of high shear in the mixer also causing the formation of very small droplets and resulting in high solvent losses was one of the most important factors affecting the choice of impeller. A number of plants operating in the metallurgical field were known to have relatively high solvent losses and an effort was made to design a mixer which would overcome this problem.

Thus if a plant is over-designed with respect to the head that the impellers can produce, the extent of recirculation can be increased and the extraction efficiency improved as the head is reduced. The alternative of partially closing a butterfly valve in the feed pipe or draft tube to increase the pressure drop in the line has no beneficial effect on the extraction efficiency and is therefore wasteful of power. Similarly, reducing the impeller speed and thus reducing the pumping head also reduces the extraction efficiency which is generally unacceptable.

Impeller Speed

The effect of an increase in impeller speed on extraction efficiency, dispersion hand thickness (depth of uncoalesced mixed phase in the settler) and entrainment has already been mentioned.

The results for all mixers show the same tendency for the extraction efficiency to increase with increasing speed until it approaches a maximum value.

The maximum value is achieved at different speeds for the different impeller designs and appears to be dependent upon the establishment of certain flow patterns and flow velocities in the mixer. Beyond this point the limitation in extraction efficiency is not one of mixing hut is more probably related to the kinetics or thermodynamics of the reaction.

The choice of impeller speed is also affected by the variation of entrainment with speed. The results shown in Figure 9 were obtained for various impeller designs and do not indicate a consistent trend. The inconsistencies may be due to experimental error but they probably also reflect a similar inherent unrepeatability that is experienced when measuring coalescence rates. There is reason to suppose from experience on a number of plants that the extent of entrainment of the dispersed phase increases with the tip speed of the impeller, and that it is desirable to minimise the impeller speed for this reason.

Organic/Aqueous Ratio

The organic/aqueous ratio (O/A ratio) is not generally considered in relation to the extraction efficiency in the mixer, the specific flow in the settler, or indeed to the entrainment experienced at the settler outlet, though it undoubtedly does have some affect upon these functions. The O/A ratio is normally fixed at a value which ensures that the desired phase continuity is achieved in the mixer. At 1:1 O/A ratio either phase continuity can be achieved depending upon which phase is covering the impeller when it is started up.

The O/A ratio beyond which it is not practical to achieve organic continuity in a mixer is considered to be about ¼ or 1/5, though theoretically by considering the fluid bulk being filled with closed packed spherical droplets this ratio would be expected to be 1/3.5. The reverse is true for aqueous continuity, though it is found that some systems appear to exhibit a preference for one continuity or another.

Settler Configuration

Firstly, the method of introducing the mixed phases into the settler is important. It has been shown by Davies and Jeffreys that by varying the level at which the mixed phase inlet to the settler is located the dispersion band depth can be varied for a given throughput, the minimum dispersion band depth being achieved when the inlet is into the dispersion band at the coalescing interface.

The flow pattern in the settler is the next important consideration and has a significant effect on both the settler area required and the entrainment produced. Uneven flow in a rectangular settler can be caused by the settler inlet and outlet weirs not being full width. For this reason a “picket-fence” baffle is sometimes located immediately downstream of the inlet and immediately upstream of the outlet in order to distribute the flow as evenly as possible over the full settler width.

The effect of the “picket-fence” as an aid to coalescence has been investigated using both organophilic and organophobic materials of construction and a small improvement has been observed when the fence is made of a material which is wetted by the dispersed phase. The use of plastic or wire mesh does under many circumstances assist coalescence and increases the allowable specific settler flow, although the susceptibility of the mesh to blockage makes its use less attractive on the large plant scale.