Table of Contents

Some of the variables encountered in the sintering of iron ores and their effect on sinter properties have been investigated at the Jones and Laughlin Ore Research Laboratory in Michigan. Ores requiring agglomeration before blast furnace utilization may be classed as coarse, intermediate or fine. Coarse iron ore is considered similar to a —¼-in. Mesabi wash ore containing some 95 pct of its particles between ¼ in. and 100-mesh. Intermediate iron ore is considered similar to our New York State magnetic concentrates in which all the particles are — 20-mesh and about 60 pct are + 100-mesh. Fine ores are considered as being at least 100 pct—100-mesh. This paper will deal only with the two coarser classifications.

hoped they will be helpful in future plant practices and design of new plants.

Laboratory Equipment and Use

Experimental Sinter Machine: The laboratory sinter machine employed in the work consists of a chamber with 1 sq ft of grate area. It is mounted on

trunnions and is rotatible to permit dumping. The chamber is connected through a 4-in. exhaust line to a suction fan. An orifice in the exhaust line and suitable taps to a U-tube permit gas flow measurements. A thermocouple in a well in the outlet of the sintering chamber is connected to a strip chart recorder and yields a continuous record of exhaust gas temperatures. The peak temperature is utilized as a reference point to measure the sintering time.

Fuel Content of Mix

The amount of carbonaceous fuel required to sinter an ore to a specified physical condition (as indicated by these tests) is less for Mesabi hematites than New York magnetites.

teristics have been and are now the subject of both physical and microscopic investigation.

Microscopic Examinations: In the microscopic work, the sinter samples are generally prepared as polished specimens and examined under reflected light. From this work it has been possible to determine the relationship of the different microconstituents, but as yet it has not been possible to determine the exact nature of the various silicates that are formed.

Water Content

Sinter mixes have an optimum water content value for maximum flow of air through the bed. Small deviations from this optimum value result in appreciable decreases in airflow. Larger deviations result in a mix that will not sinter because it is too wet, or a mix that is partially pulled through the grate bars because it is too dry. The optimum value for any mix varies with the particle size distribution and the nature of the ore.

In the operation of tonnage sinter plants, close control of water in the mix is difficult. Plant application of moisture control is hindered by (1) variations in moisture content of raw materials, (2) large time lag between bins and swinging spout, (3) use of crude returns of varying size and temperature, and (4) lack of availability of a fast recording or indicating continuous moisture meter.

Solid Additions to the Mix

A bed of ore being sintered will have at least four general zones or layers of materials as follows: (1) Sinter layer, (2) fusion layer, (3) dried-out layer, (4) mix layer. Each layer will vary considerably in its permeability, thereby affecting the sintering rate. Coarse ores such as undersize wash ores exhibit a much higher sintering rate than intermediate size ores. In our plants there is a 25 pct difference in sintering rate between a coarse ore with about 95 pct of its particles between ¼-in. and 100-mesh and an intermediate size concentrate with some 40 pct —100-mesh. Attention, therefore, has been directed towards the possibility of improving the overall permeability of the sinter bed by improving the permeability of the zones or layers of material present during the sintering operation.

Effect of Cooling Rate on Sinter

Water cooling of sinter, compared to air cooling, has been the subject of some discussion in the last few years. Saussaman in 1948 reported that air cooling of sinter had reduced the amount of —1/8-in. sinter from 23 pct to between 3 pct and 8 pct at the Kaiser Plant in California. Tests in our plants and laboratory show that a decrease in the degree of drastic cooling results in improvements in this respect.

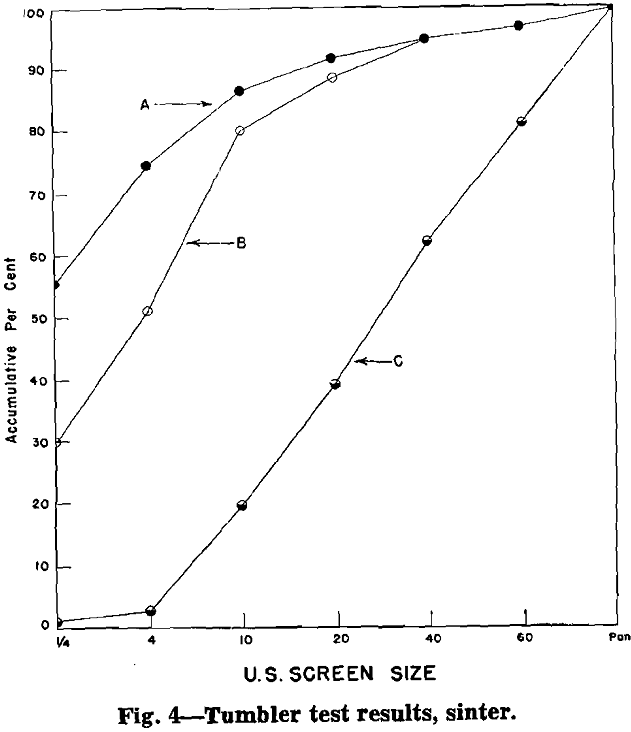

A pronounced difference in crush and tumbler results between the two differently processed sinters. These results represent extreme conditions of cooling not usually encountered in commercial sinters. However, the spread between curves is large in both cases and undoubtedly represents a major change in physical properties.

The differences between water-cooled and air-cooled sinters has been further studied with the microscope on experimental laboratory heats. An examination of the microstructures of two water-cooled magnetite sinters revealed the following:

- Watercooling alters the microstructure of magnetite sinter more drastically than it does that of hematite sinter.

- More silicate binder is present in water-cooled sinter than in air-cooled sinter.

- Silicate binder is more massive in water-cooled samples than in air-cooled samples.

- Magnetite grains in water-cooled samples are not as coarse as those in air-cooled samples.