Table of Contents

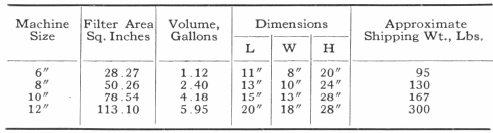

Slurry Pressure Filter

With the Slurry Pressure Filter it is possible to dewater a great number of mill samples every day. The quantity of pulp to be filtered at each operation will determine the size best suited for your requirements.

Because of an ingenious arrangement of the yoke, it is impossible to open the filter without first releasing the air pressure. The yoke cannot be removed until the “Quick as a Wink” connection has been severed. This safety pressure type of filter is essential for use in universities, schools, and test plant laboratories. It can be used as either a vacuum or pressure filter.

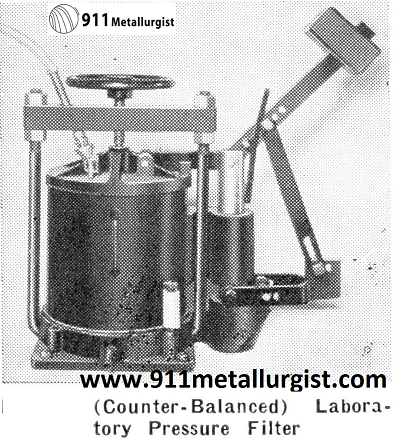

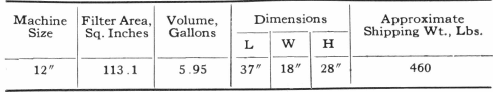

Laboratory Counter-Balanced Pressure Filter

Laboratory Vacuum Filter

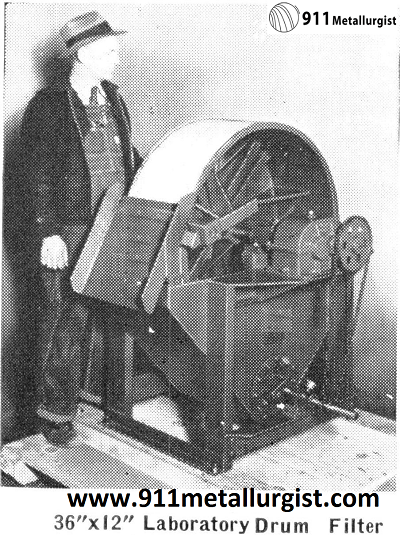

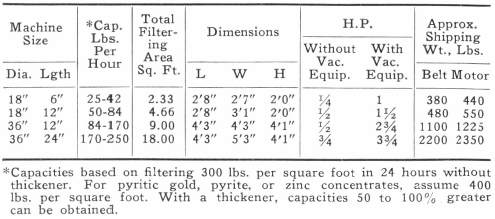

Laboratory Drum Filter

The Laboratory Drum Filter is an ideal unit for every laboratory in working out continuous filtering problems. It will successfully dewater finely ground materials such as flotation concentrates and cyanide tailings to secure the best washing and drying of the filter cake. The filter capacity and moisture content and the nature of the cake depend upon physical characteristics of the material handled. This filter is a practical unit for continuous laboratory test plants, schools and commercial laboratories as well as pilot test plants. It is equally valuable in industrial and chemical laboratories wherever it is necessary to save water for reuse, or dewater solids.

This unit has a drum cast in one piece with integral pipe connections and port which reduces first cost and maintenance cost. The pipes cast in the drum are large with steep sloping drains and no sharp corners. The drum is vacuum and pressure tight and will not warp or leak even if operated intermittently. Drum is of cast iron but can also be furnished in an alloy metal, depending upon the material to be filtered. The valve assembly consists of two sections; the valve which rotates in a heavy cast iron trunnion and carries the filtrate piping, and the valve port plate which is stationary and adjustable for regulating the filter cycle. There are two connections in the valve port. The tank is made of steel, strongly welded and with extra heavy structural supports. Filter is driven through a totally enclosed worm gear reducer which runs in an oil-tight housing.

Laboratory Drum Filters, in sizes up to and including the 3′ diameter x 2′ length, have drums cast in one piece. Sizes larger than the 3′ diameter have the drums made up of cast iron filter segments. For pilot plant operations requiring filter capacities greater than 3 tons per 24 hours, 4′ and larger diameter filters are available.

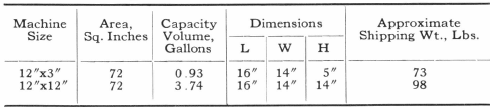

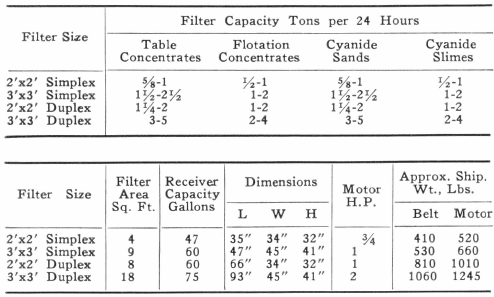

Laboratory Pan Filter

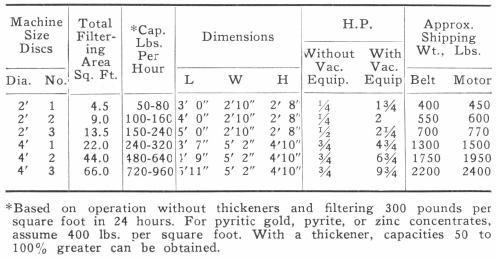

Laboratory Disk Filter

The adjustable valve mechanism permits accurate setting of valve position to suit operating conditions. Oversize filter parts and piping provide rapid removal of filtrates. The steel filter tank is of double welded construction. The tanks for two or three disc units may be furnished with partitions for filtering several products simultaneously. As the capacity of a filter depends largely on the nature of the material to be filtered, particularly the amount of fine material and slimes and the percent solids, preliminary tests should always be made.

Source: This article is a reproduction of an excerpt of “In the Public Domain” documents held in 911Metallurgy Corp’s private library.