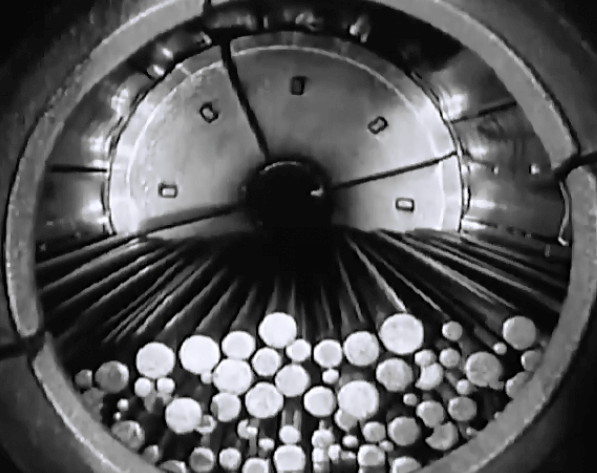

Many grinding problems requiring a minimum amount of fines can be solved by the Laboratory Rod Mill which assures a uniform product without overgrinding. It can be used as a batch ball mill or as a continuous grinding unit. The mill can be rotated at any angle, being held in position by the handwheel clamp. If the mill is rotated vertically, the entire charge can be emptied with a minimum amount of wash water; and a grate discharge holds back the rods or balls depending upon grinding medium.

|

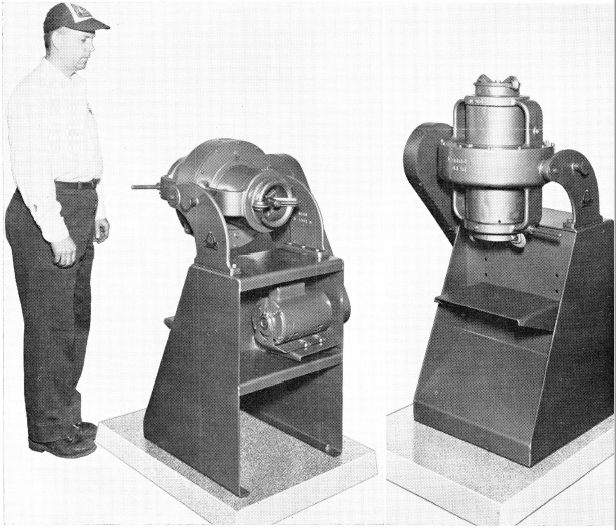

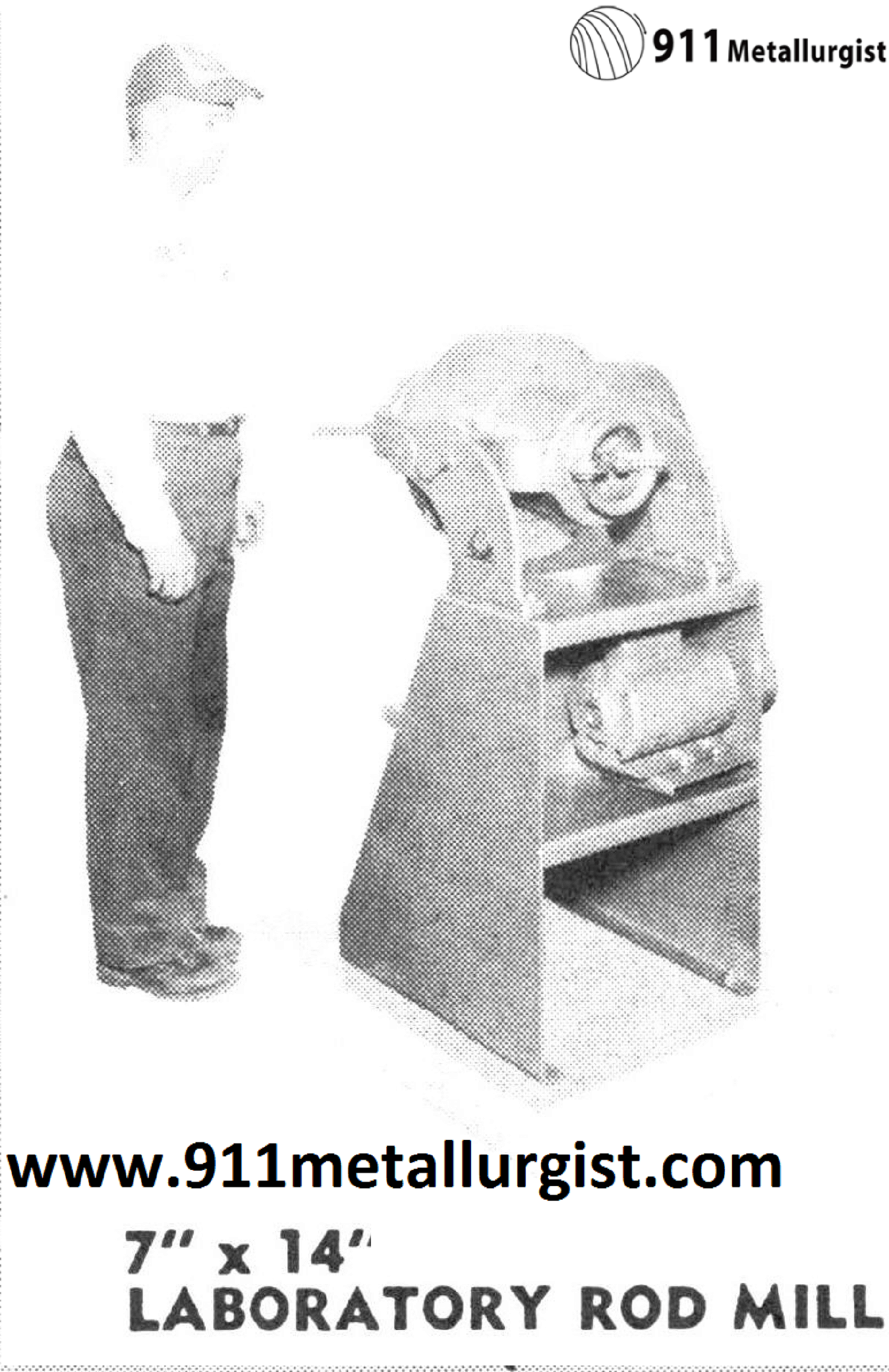

The Laboratory Rod Mill can either be mounted on a steel frame (as shown in the illustration above), or bolted to a laboratory bench. The grinding drum can be easily and thoroughly cleaned out as it is a single casting with round corners.

7″ x 14″ LABORATORY ROD MILL AIDS PROCESSING RESEARCH

Many process flowsheets require grinding with a minimum amount of fines. For years the Laboratory Batch Rod Mill has been a popular unit for developing such processes. The older unit has now been re-designed, simplified, and modernized.

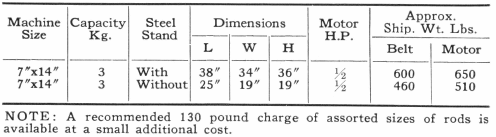

Capacity of the 7″ x 14″ Laboratory Rod Mill is 3 Kg. The unit comes complete with rod charge, steel base, motor, drive, and drive guard. Wet or dry grinding is accomplished with the mill operating locked in the horizontal position. For charging and emptying the mill, it is tilted on its axis. The mill stand has an adjustable shelf so that containers of varying size can be used for holding mill discharge.

Portability and compactness make this grinding unit a valuable tool in every testing laboratory. It can be used as a ball mill by replacing the rods with grinding balls. A grate discharge holds back the grinding charge. Mill can be operated in any position for washing or cleaning.