Table of Contents

Microscope

Quick determination of a sample can often be made by means of a microscope. Over-all losses can be reduced even in a flotation circuit by examining the various test plant products with a microscope without waiting for the return of assays.

The general purpose microscope is also being extensively used to determine the association of minerals by examining the polished surface made with a Laboratory Specimen and Rock Cutter. Equipment Company carries a line of practical, inexpensive microscopes to supply the needs of mill laboratories and prospectors. These simple microscopes are available with magnifications ranging from 30 to 300 diameters. Fitted for examining either opaque or transparent objects, types with or without stages and stands may be obtained.

By eliminating accessories such as iris diaphragms, Abbe condensers, and fine focusing adjustments, these microscopes are made obtainable at very low cost although built along the lines of larger microscopes. Inspection microscopes are also available for examination of surfaces, cutting edges, and cut sections of metals.

Binocular

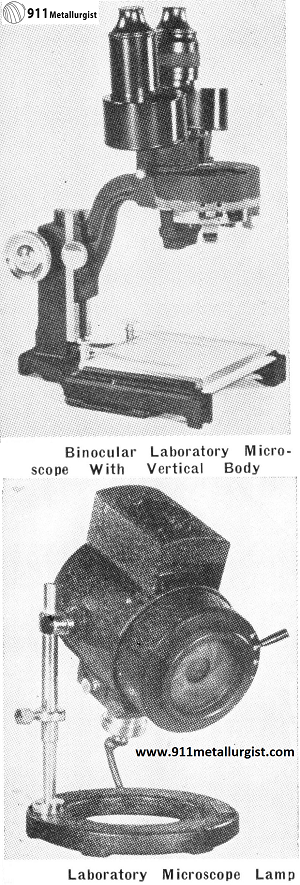

The Binocular Laboratory Microscope, because of its depth of focus and wide field, clearly brings into prominent view features not otherwise observed with the ordinary monocular microscope. It is for this reason the binocular microscope is considered standard equipment in mill control and ore dressing research laboratories.

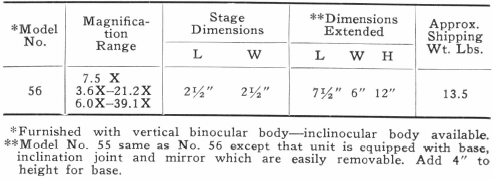

This microscope has a removable glass stage and the arm may be lowered to a point where, with the glass stage removed, it may focus on any portion of a large area which the instrument is placed upon. It may be equipped with paired eye pieces and objectives to obtain magnifications from 3.6 up to 210.0 times. Magnifications of 39.1 and 115.6 are recommended and in general will fill the requirements of the average laboratory investigating minerals and mill products.

In locations where a bright light is not available a microscope lamp, as shown in the illustration, is recommended.

The lamp uses a 100 watt, 115 volt bulb and condensing lenses project the light as a brilliant spot onto the microscope field. The size and intensity of the spot of light is controlled by moving lamp in slide way and by a diaphragm.

Laboratory Mineralight

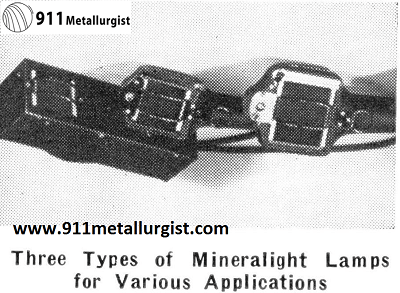

The Laboratory Mineralight, as it is used in ore dressing or mineralogical laboratories, provides a simple means for making preliminary checks by flourescence to identify minerals that might otherwise be overlooked or require difficult chemical tests to detect.

It can also be used for determining nature of gangue minerals, quickly evaluating grade of test products, or determining best grind by showing mesh at which mineral is liberated. If a commercial size unit will be used in the commercial plant for sorting mill feed ore, continuous test- work would obtain no indication of possible recoveries without test ore being sorted by Mineralight.

One very important application of the Laboratory Mineralight is the vapor test for mercury. The unit is so sensitive and accurate that 1/1000 of 1% of mercury can be detected; thus, leaks of poisonous mercury vapor from retorts can be detected before they become dangerous to personnel doing the retorting.

The Mineralight is a simple, light weight instrument. It is now being used in almost all educational, research, industrial, and ore dressing laboratories.

The Mineralight is available in nineteen different models. It may be equipped for 110 volt alternating current, battery operation, or a combination of both. The intensity of the lamp depends on the amount of quartz tubing placed in the lamp. The standard lamp is furnished with a set of identified fluorescent minerals and operating instructions. Auxiliary items such as willemite screens for mercury detection, standardized scheelite analyzer cards, etc. are also available if desired for particular applications.

Source: This article is a reproduction of an excerpt of “In the Public Domain” documents held in 911Metallurgy Corp’s private library.