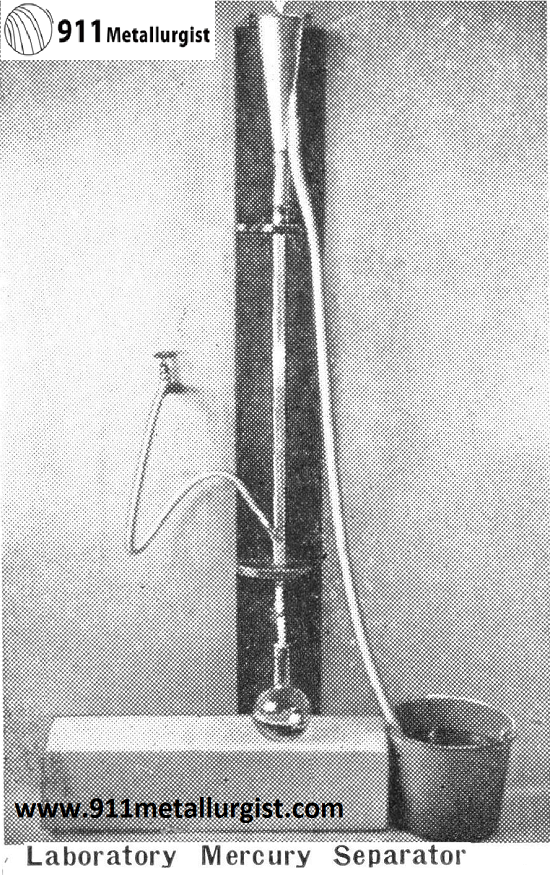

Laboratory Mercury Separator is extensively used to separate floured mercury or amalgam from the tailings of any amalgamating unit.

Pulp is fed into the tube through the funnel in the top, and water is forced in at the lower part of the tube, creating a sufficient up-current to overflow the sands out of the discharge outlet near the top. Mercury and amalgam are of sufficient specific gravity to drop down through the up-current of water and collect in the removable mercury flask at the base of the tube. Water pressure at the inlet is regulated by a valve and when it is correctly controlled, very accurate discrimination can be obtained.

This mercury separator is also used for cleaning up amalgamated sands and concentrates, being quick and accurate. This unit can be made in commercial sizes for large placer, amalgamation mill, and dredge work.

Mercury

Mercury for use with amalgam plates and barrels, ball mills, clean-up pans, etc., can be furnished at the prevailing market price. Specially designed metal containers can be supplied in a number of convenient sizes. These metal containers avoid spillage and breakage and can be easily transported. Large flasks contain 75 pounds and smaller sizes, 5, 10, or 25 pounds of mercury.