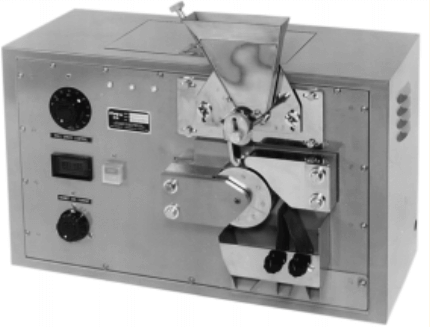

This Laboratory Magnetic Separator is a high intensity dry device which uses a rotating iron disc to concentrate the magnetic field and remove the magnetic particles from the non-magnetic. It essentially consists of an electromagnet (the applied current is controlled by a rheostat) which produces a magnetic field across the air gap and a belt which passes through the air gap. Mineral particles are fed from a vibrating feed onto the belt and through the magnetic field. The magnetic particles are attracted to the disc above the belt and from there are removed from the field by the disc above the belt and from there are removed from the field by the disc’s rotation – they fall from the disc and are collected at the side of the belt. The non-magnetic particles are collected at the end of the belt.

- The machine should be thoroughly cleaned with compressed air, and the product collection trays placed in position.

- The sample to be tested should be closely sized (ex: 425-300 microns, 75-45 microns) and Ferromagnetic particles removed prior to separation (a hand magnet inside a plastic bag may be used for this).

- Place the sample in the feed hopper.

- The air gap between the disc and the belt should be set to approximately treble that of the largest particle in the sample (NOTE: The air gap cannot be adjusted when the current is on).

- Press the mains “START” button and turn on the three switches (feeder, magnet and belt disc drive).

- Slowly increase the current to the required level (indicated on the ammeter) by turning the current rheostat – some experimentation may be necessary to determine the amps required (NOTE: reduce current to zero before switching the magnet off).

- Slowly start the vibrating feeder and adjust such that a single layer of particles is distributed over the belt (periodic adjustment may be necessary).

- Once optimum separation is achieved, switch off the feeder, recombine the products in the feed hopper and commence separation.

- When the sample has run through, collect, weigh, label and bag the products.

- Repass the non-magnetics at a higher current if required.

- Reduce current to zero, turn off all switches, clean the machine thoroughly