Laboratory Leaching tests of mine wastes are typically performed using procedures that fall into two basic categories: batch and continuous. These categories are analogous to batch and continuous reactor methods used in metallurgical processing. Batch reactors for leaching tests can be in the form of a closed vessel, a cell, or a column. A continuous reactor for leaching tests usually takes the form of a column. There are many variations on these two types, and what looks like a column leach test apparatus may actually be configured as a batch test, depending on the test design.

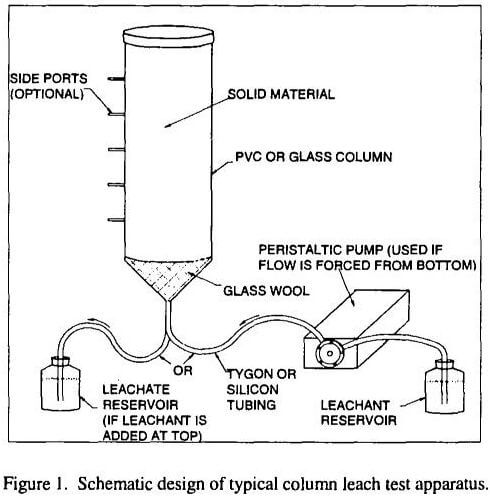

Continuous column leach tests are typically conducted by filling a length of pipe or tubing with a solid sample and continuously passing water (or another leachant) through the sample for a specified period. Leachate samples can be collected at any desired frequency and analyzed for any constituent of interest. There are many variables in column leach test design, including:

- Column length and diameter

- Flow type (forced flow from bottom or gravity flow from top)

- Flow rate/residence time

- Sample pretreatment (particle size reduction, oxidation, bacterial inoculation)

- Leachant composition (water or other reagent, sparged to remove O2, etc.)

Column tests are well-suited to determining the concentrations of constituents that can be released over a relatively small number of pore volumes, which corresponds to shorter time periods. The design of a typical column leach test apparatus is depicted in Figure 1.

Batch leach tests are conducted by mixing the material to be leached with water (or another leachant) at a specified ratio in a vessel, allowing contact of the contents (often with mixing or agitation) for a specified period, and separating and analyzing the leachate for the constituents of interest. Batch leach tests can be designed to represent the contact of the tested material with many pore volumes of leachant and can be conducted in a much shorter period than column tests simulating the same number of pore volumes. This shorter time typically translates to lower costs for conducting the test and analyzing leachate samples. Variables to be considered in the design of batch leach tests include:

- Configuration of extraction vessel

- Duration of extraction

- Method of contact (nonagitated, TCLP-type rotary extractor, wrist-action shaker, other)

- Solid:Liquid ratio

- Number of sequential leaches

- Sample pretreatment

- Leachant composition

Kinetic tests are a type of batch leach test and are used to evaluate the ability of a rock sample to generate acid under conditions that simulate accelerated weathering. A commonly used type of kinetic test uses a humidity cell, typically a plastic box with inlets and outlets for air and water, as a reaction vessel. Weekly cycles consisting of flushing with dry air, moist air, and water to remove reaction products are conducted, with each week the equivalent of one batch leach. Kinetic tests can also be configured to use a column as the reaction vessel, but this configuration is still essentially a batch leach test.

An issue that must be considered when designing any leaching test is the rate of chemical reactions that control leachate constituent concentrations. Because these tests are necessarily run over shorter periods than the processes that will occur in the real-world system being simulated, reactions that occur slowly in nature might not have sufficient time to be adequately represented in a leaching test. Preliminary tests to monitor changes in concentration over time can be used to demonstrate that the extraction time is sufficient for leachate concentrations to stabilize.

Comparison of column and cell kinetic test results for pit wall rock

The second case study consists of a project for which a sample of potential wall rock from a proposed open-pit gold mine was tested by two types of modified humidity cells to characterize the release of constituents from the rock after oxidation. One cell was set up in a rectangular plastic box (Figure 4), while the other utilized a column (Figure 5). Both apparatuses were evaluated to see if small differences in setup would affect the results.