LABORATORY FLOTATION MACHINES: These machines are being used throughout the world for floating all kinds of metallic minerals including gold, as well as non-metallics such as graphite, fluorspar, coal, etc. When operating a laboratory flotation cell, the results obtained can be duplicated in practice as these units are designed on the same principle as the commercial machines.

These Laboratory Flotation Machines are of the mechanical, rotating impeller type and has the following distinctive features: gravity flow circulation from cell to cell which eliminates pumps and elevators, including the return of middlings from one cell to another by gravity; standpipe around rotating shaft sucks sufficient air for flotation without the use of blowers or air under pressure; stationary hood over impeller directs all pulp feed to top of impeller where all the pulp is thoroughly mixed and aerated. The stationary hood also allows immediate starting after a shutdown without draining or choke-ups.

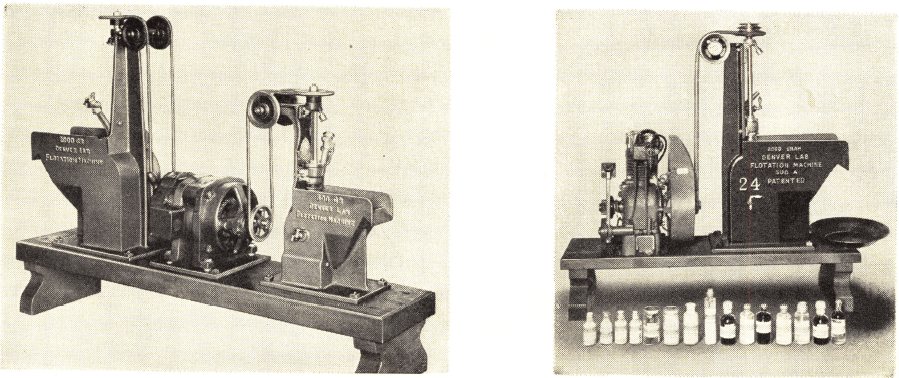

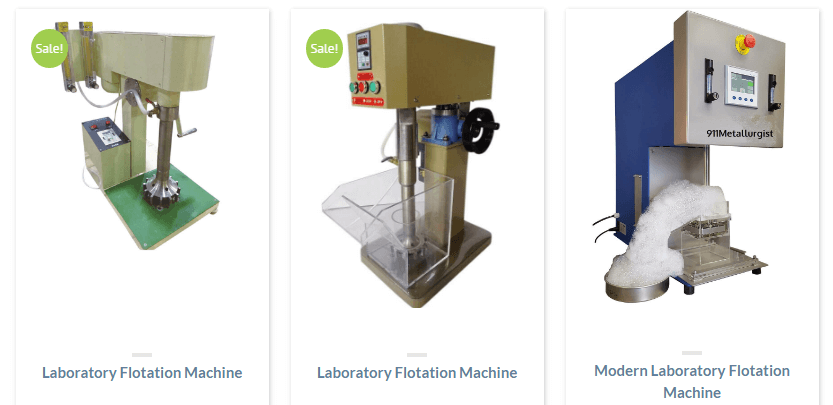

Accurate calculations in laboratory experimental work demand units of standard requirements, and it is for this reason that laboratory “Sub-A” flotation cells are built in three sizes:

2000 gram, 1,000 gram and 500 gram. Usually the 2,000 gram size is used for roughing and a 500 gram unit for cleaning the product without dilution (note combination unit below). Simplified design eliminates all lost motion of the operator. There is a convenient valve on the standpipe which gives positive control of the air introduced into the pulp. A spigot is located below the froth level for quickly drawing off samples of the pulp for examination.

The type of drive can be furnished as desired, standard belt drive, mule drive or quarter turn (using standard motor); the 2,000 gram machine only, can be supplied direct connected to variable speed motor. A set of sample reagents is included with each machine as shown in illustration of gasoline driven Laboratory Flotation Machines.