Table of Contents

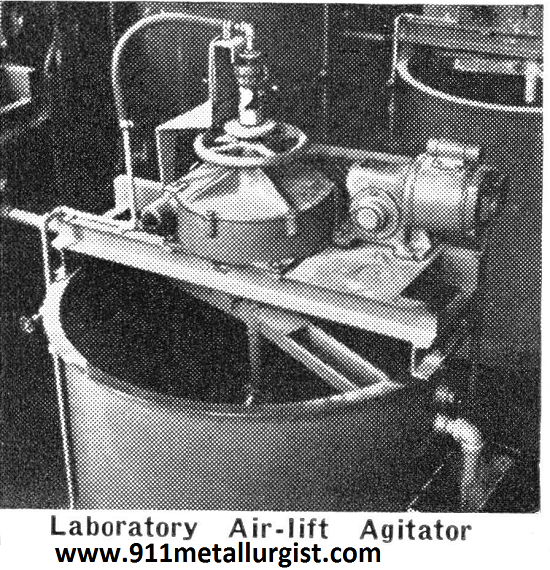

Air-lift Laboratory Agitator

Laboratory Air-lift Agitator was specially developed for use in continuous testing laboratories and pilot plant operations. This agitator is similar in design to a large scale continuous commercial agitator and accordingly the results obtained can be directly calculated for the large tonnages of commercial operation.

Gear drive mechanism is totally enclosed, with integral rake lifting handwheel. Rotating paddles maintain pulp in suspension. Air-lifts and distributing launders can be furnished for central agitation or at the periphery of the tank. Steel tank is furnished as standard. Unit is completely self-contained and can easily be moved as various flowsheet arrangements may require.

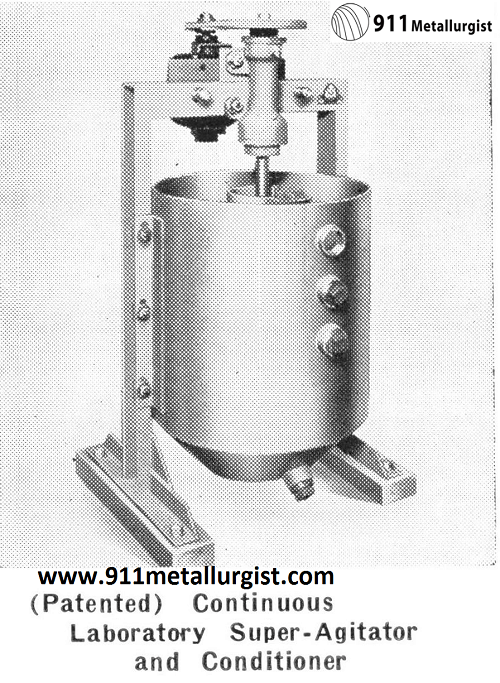

Batch and Continuous Laboratory Agitator

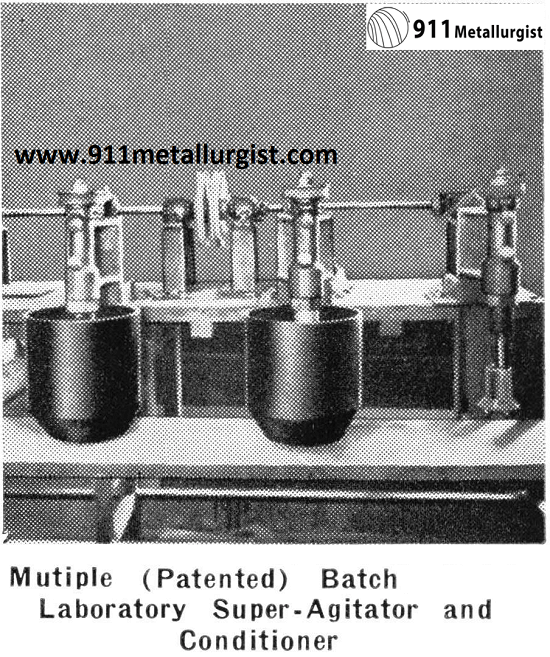

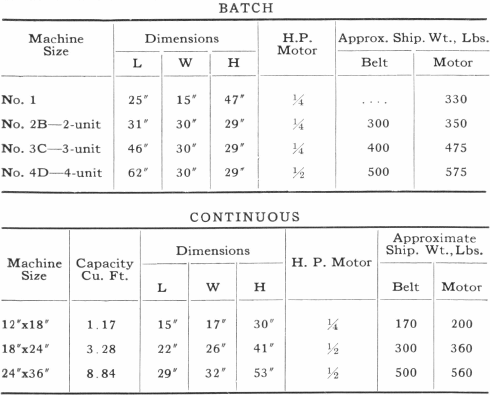

Single batch, multiple batch or continuous (Patented) Laboratory Super-Agitator and Conditioner is available to meet the needs of small or large batch laboratories or continuous pilot test plants. This agitator is designed for use in metallurgical, chemical and process laboratories to agitate, condition, aerate, or mix any combination of liquids or liquids and solids which will flow through a 10 mesh screen. It is distinctive in that it is particularly well suited to any job requiring intense agitation and aeration and for handling pulps of high density and those containing high specific gravity solids . . . the kinds of material so difficult to handle in ordinary types of agitators and conditioners. Both batch and continuous units are compact, efficient, and easily cleaned. The results of testwork conducted by the continuous unit can be duplicated by the commercial size while batch unit results may be closely approximated in commercial practice.

The (Patented) Batch Laboratory Super¬Agitator and Conditioner is a simple, flexible unit, low in cost and durably constructed for dependable operation. This unit approximates as closely as possible the operation of the commercial (Patented) Super-Agitator and Conditioner in batch testwork.

The patented central stand pipe provides positive and con-trolled circulation and aeration. Feed enters the stand pipe and is positively circulated by the propeller . . . thus, there is no possibility of the material short circuiting across the agitator and no settling of solids. Flow of pulp down the standpipe, combined with rotation of propeller, pulls air into the propeller zone where it is finelly disseminated throughout the pulp.

Multiple agitator units, as shown at the left, are available to agitate several pulps simultaneously. A number of units can be mounted on a single base, with individual rubber covered supports and driven by V-belts from a common shaft.

Three sizes of heavy cast spherical bottom Pyrex jars and two agitators are furnished as standard equipment with the single unit. These jars have a capacity of 1.75 Gals. (6.62 Liters), 3.37 Gals. (12.75 Liters) and 5.03 Gals. (19.03 Liters).

The (Patented) Continuous Laboratory Super-Agitator and Conditioner accomplishes the agitation of pulp in the continuous laboratory or pilot plant that produces results that can be duplicated in commercial practice.

This unit is ideal for use in continuous cyanide test work, as each sample can be thoroughly agitated, with intermediate discharge points allowing adjustment of agitation time.

This machine is rugged, self-contained, and easily portable. Unit is equipped with an all¬steel tank which may be drained completely through a plug in the conical bottom. The superstructure supports the shaft with totally enclosed ball bearing housing, and motor drive. The motor is fitted with variable pitch motor sheave and V-belt. This agitator can also be used as a pulp storage tank, as a source of constant feed to a concentrating table or filter, or as a conditioner.

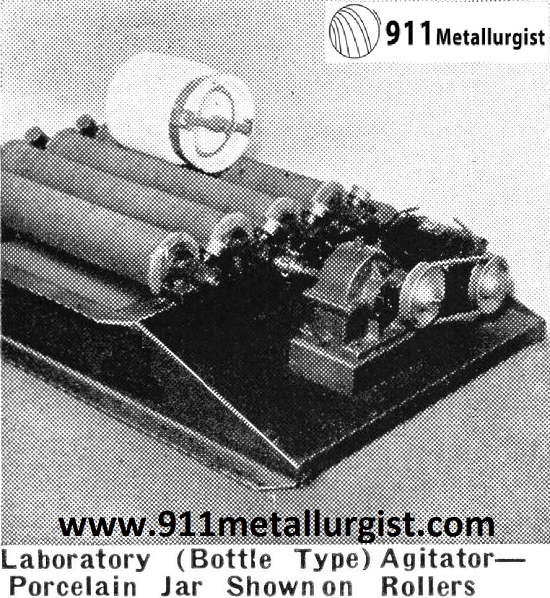

Bottle Type Laboratory Agitator

The Laboratory (Bottle Type) Agitator is being used for all types of pulps, particularly cyanide, and as a jar pebble mill. Large ammonia bottles filled with pulp can be agitated continuously for any length of time. Two large bottles or as many as six small bottles can be used at the same time, which provides a very flexible type of agitation. The speed reducer and chain mechanism drive is positive, as shown in the illustration, and the entire unit is mounted on a steel base. Idler roll is easily adjustable to practically every bottle size.

Jars are manufactured in many sizes and styles for various capacities and conditions. All jars are made of the best material, and three kinds are available: (1) Porcelain Jars—carefully molded and fired to obtain the proper degree of vitrification so as to give acid and wear resisting qualities for agitation and grinding. (2) Metal Jars—made of metals most resistant to the action of a grinding charge, such as Monel, stainless steel, cast steel, and bronze. (3) Pyrex Jars—are transparent and enable observation during grinding or agitating action.