It has long been recognized that the conventional method of producing lead bullion from concentrates via the sinter-blast furnace route presents problems in meeting the tight regulations for environmental protection which have been introduced in many countries. As described by Chaudhuri and Melcher, 1978, this has led to the development over the past decade of various processes aimed at the production of lead directly from concentrate in a single furnace.

Features of Kivcet metallurgy

Of the new lead smelting processes Kivcet is the only process which offers the potential operator the choice of simultaneously recovering the zinc, which inevitably occurs in the lead concentrate, as a saleable product. Zinc sulphide as well as other metallic sulphides in the concentrate are oxidized with technical grade oxygen in the smelting shaft of the Kivcet furnace.

Alternatively, the amount of reducing agent fed to the furnace can be controlled so that minimum fuming of zinc takes place and a slag suitable for dezincing in a conventional slag fuming furnace or Waelz Kiln is tapped. Recent pilot plant test work has shown that it is possible to selectively reduce lead oxide from the oxidised melt produced in the smelting shaft by the charging of specially sized particles of carbonaceous reducing material to the smelting shaft. Selective reduction takes place by means of intimate mixing of the molten oxidised charge and the hot coke layer on the surface of the bath directly under the smelting shaft at reaction rates which exceed those in the electric furnace.

Pilot plant test results have also shown that the process is very flexible with regard to the type of lead-bearing feed to be smelted. Apart from high grade lead concentrates, complex lower grade concentrates containing relatively high amounts of accompanying metals, as is the case with the SCMK feed material, have been successfully smelted.

Features of the Kivcet smelter in Bolivia

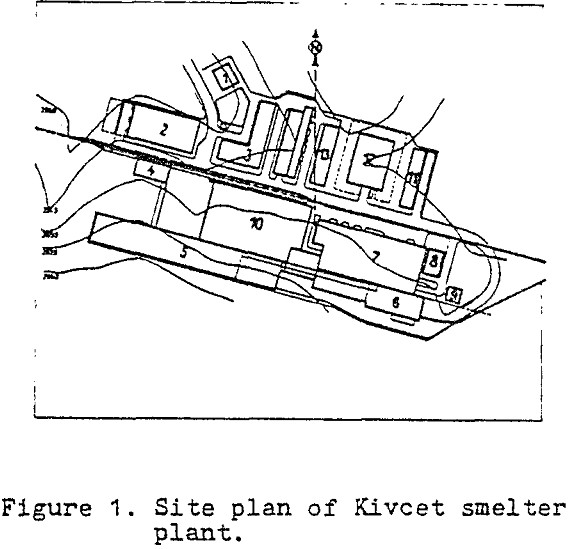

The plant is situated near the town of Potosi at an altitude of 3 950 m. The atmospheric pressure at this altitude is only about 64 kPa, which has to be taken into account when designing the plant, particularly the furnace off-gas systems. At this altitude the cross sectional area of a duct for a certain gas flowrate in normal cubic metres per hour must be 60 percent larger than that at sea level, if the gas velocity through the duct is to be the same. Allowance must also be made in defining the capacity of electric and diesel motors, compressors and fans. Since the boiling point of water is only 360 °K care must be taken in the design of cooling water systems.

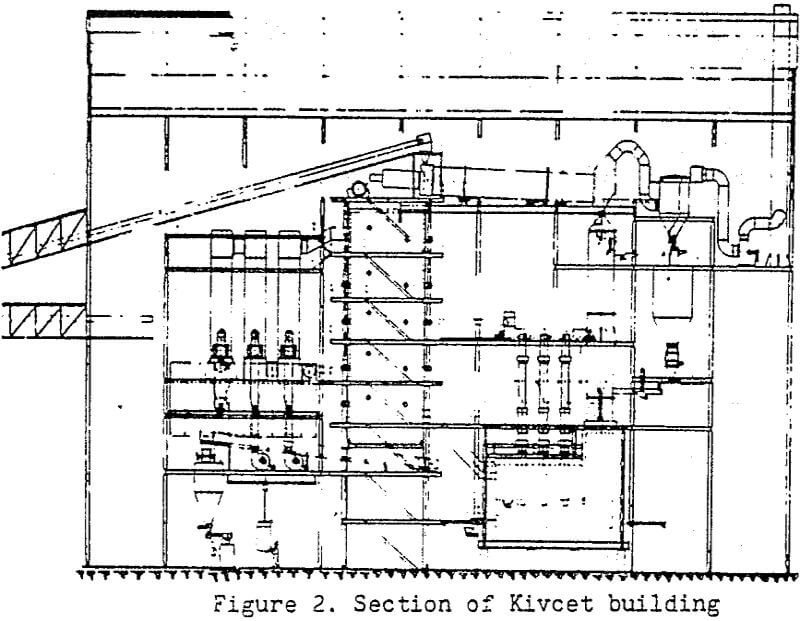

The furnace is a steel-shelled closed reactor which operates at slightly negative pressure with respect to the prevailing atmospheric pressure. Thus, under normal operating conditions, fugitive gas and fume emissions to the surrounding environment are eliminated.

Since the electrode openings are constantly purged with a small flow of nitrogen, emission from this region is also eliminated. Tapping areas and launders are enclosed to the maximum extent whilst still allowing access to the working areas. Ventilation air flowrates provide the required space velocity at openings, to ensure that no fume escapes to the working environment.

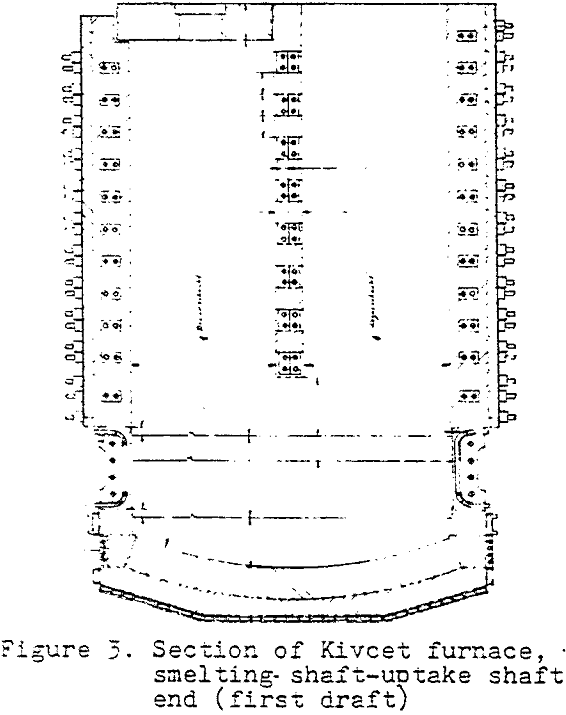

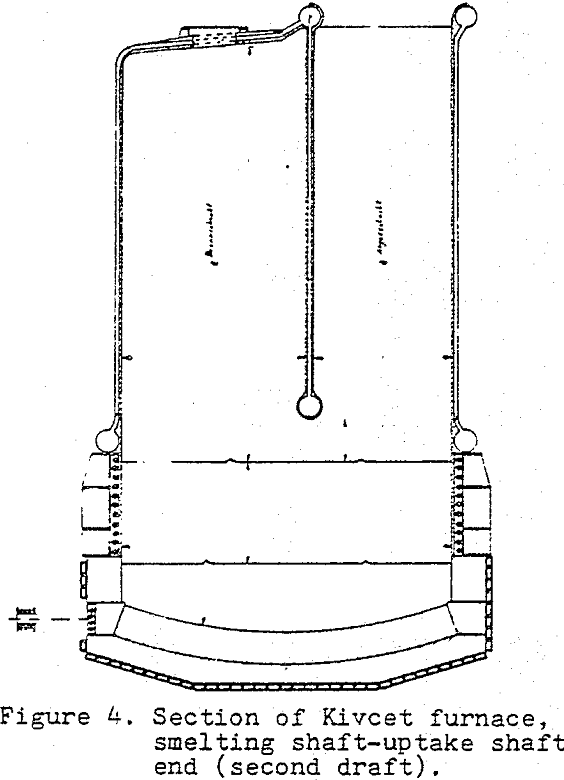

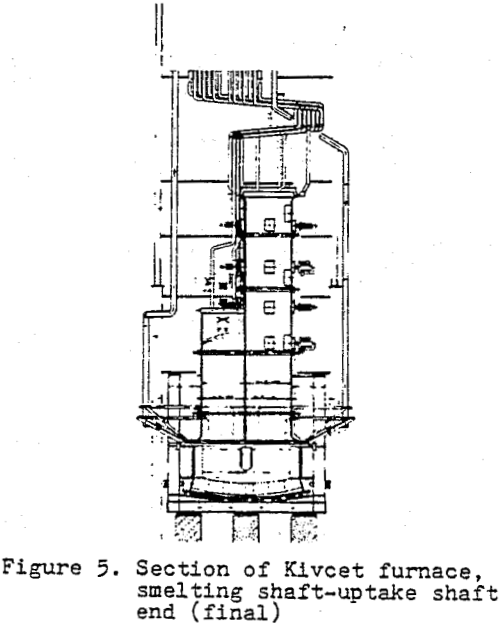

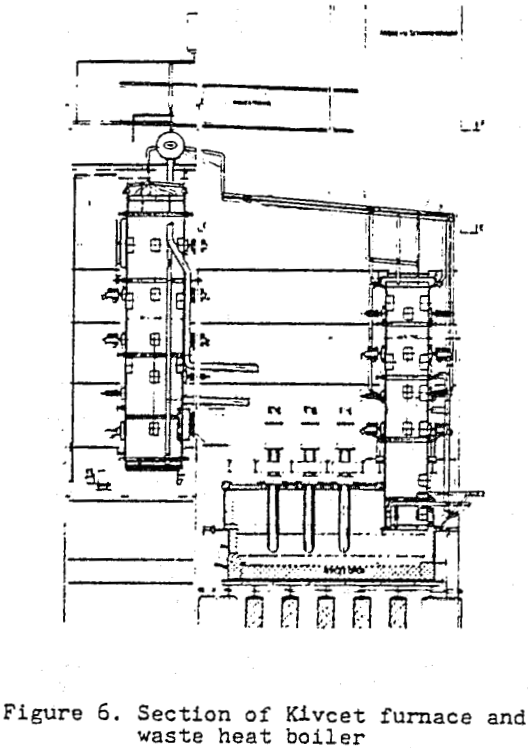

In the smelting shaft the mixture of sulphide concentrate, recycled refinery products, limestone, the fine fraction of the charcoal and recycled electrostatic precipitator dust reacts with technical grade oxygen whereby sufficient heat is generated to smelt the charge and to produce temperatures of 1 623 – 1 673 °K. The smelting shaft is square in section and 5 m in height, with the gas uptake shaft situated immediately adjacent to the smelting shaft.

The gas leaving the smelting shaft passes under the wall which separates the smelting and uptake shafts and is cooled while passing up the uptake shaft. The gas temperature at the uptake shaft exit is 773 823 °K. The uptake shaft is also constructed out of boiler tube and, together with the smelting shaft, forms a single boiler unit.

Coarse charcoal particles are charged to the electric furnace in order to fume metallic zinc from the slag. The gas mixture above the electric furnace slag bath consists of metallic zinc and lead vapours as well as carbon monoxide, and would be partially oxidised by any ingress air finding its way into the fumace.