Table of Contents

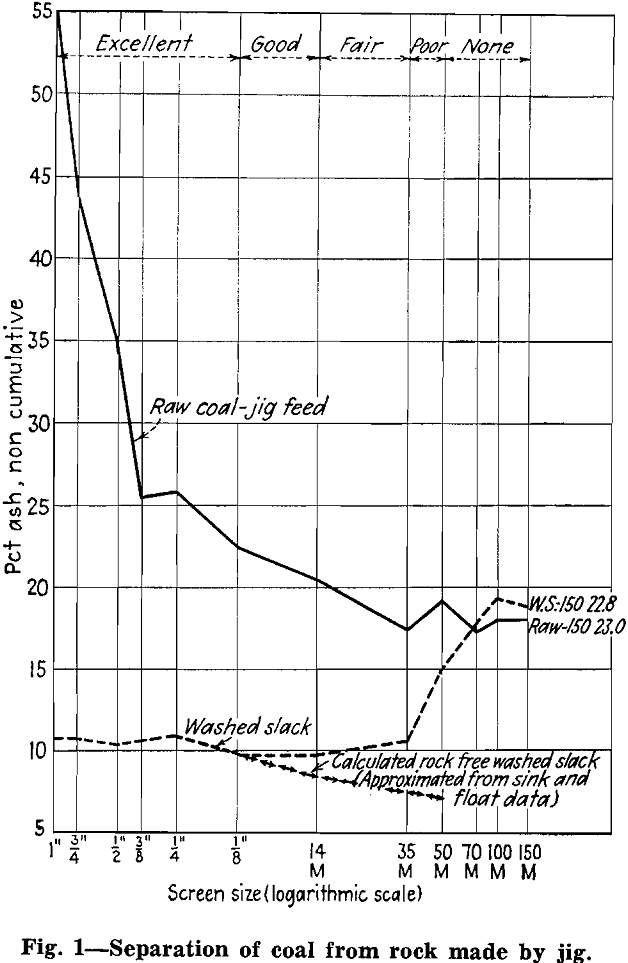

In cleaning coal it has long been recognized that methods which give excellent results for the coarser sizes may give poor or even no cleaning for the finer sizes. Effective cleaning of the fines, therefore, is usually a separate and distinct problem. For many years the problem of fines was considered of relatively minor importance.

Development of Fine Coal Cleaning Problem

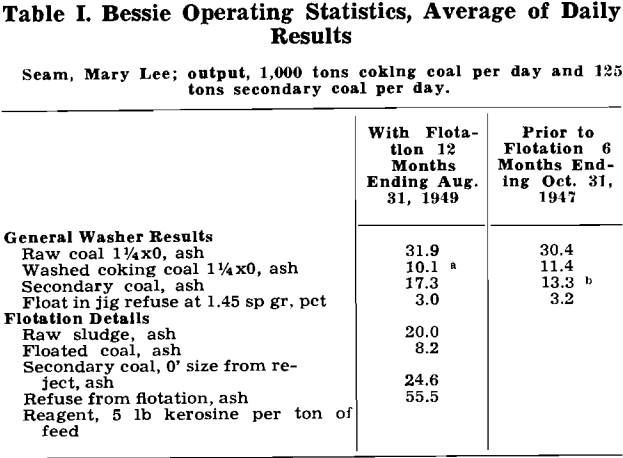

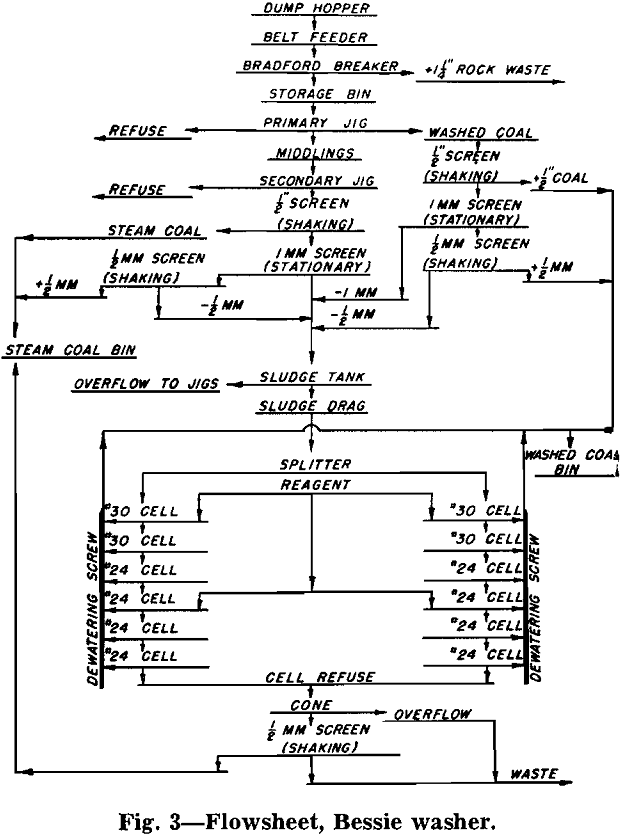

In 1942 Sloss reopened its Bessie mine and constructed at this location a new preparation plant to clean 1¼ in. x 0 coal from the Mary Lee seam.

A McNally Norton (Baum type) five-compartment primary jig and a similar two-compartment secondary jig were installed. Contrary to the company’s previous practice, the installation included 1-mm screens for dewatering the washed products and a sludge settling tank for recovering the solids in the screen underflow. With this plant in service, the —1-mm fines became separately available prior to mixing with the coarser coal. Samples analyzed for ash then revealed a fine coal cleaning problem because, with the coarser coal having an ash content of about 10 pct, the sludge ash was about 15 to 20 pct.

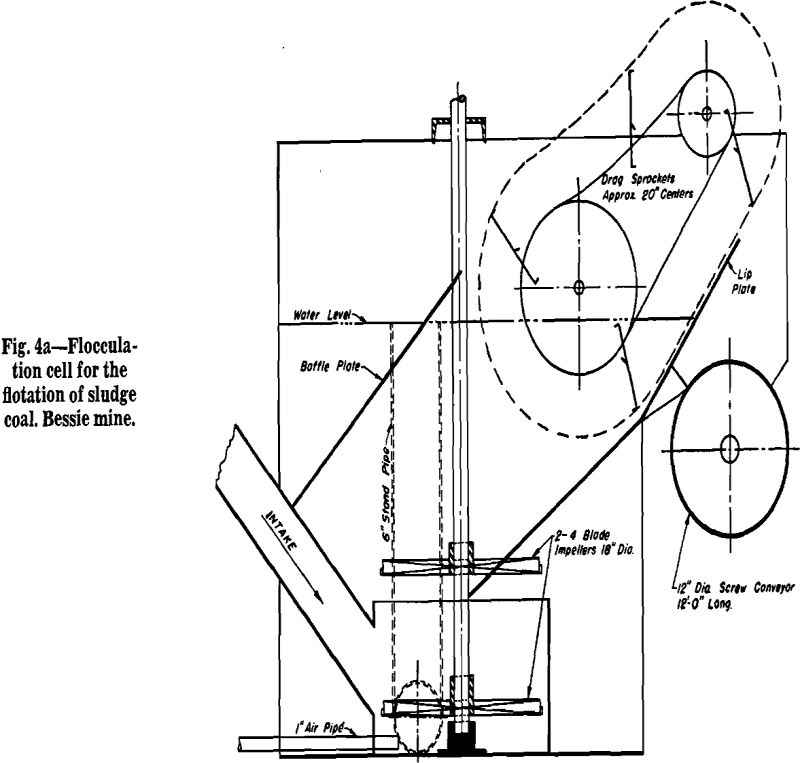

Experimental Cell Installations, Bessie

Thus it became established definitely that below a size of about 1 mm the jigs were not making a good separation and that some better method was needed for cleaning coal below this size. Meanwhile, B. W. Gandrud, of the Bureau of Mines, had discussed with Sloss some of the very interesting results he had secured in laboratory experiments using kerosene flotation for fine coal, and the Sloss-Sheffield Co. became interested in proving the feasibility of the method on a larger-than-laboratory scale.

Flotation of Raw Coal, Kimberly Plant

The feed to the Bessie flotation plant is a sludge or fine material which has already been washed in the jig plant and from which the extreme fines have been removed by classifying action in the settling tank. Experimental work by Gandrud had shown that a raw coal feed could be handled as effectively as sludge except that conditions for dewatering were more exacting. There are a number of advantages to be gained by floating raw coal, such as:

- All the fine coal, including the finest sizes, are retained as cell feed so that coal otherwise lost in the effluent from the plant may be recovered. Based on determinations of solids in the effluent, this loss at Bessie is estimated at 20 tons per day.

- Added washer capacity may result. The removal of fines from the equipment for washing the coarser sizes may allow this equipment to operate at greater capacity, thus increasing the overall washing capacity of the plant.

- The removal of the fines may permit better jig performance.

- The removal of the fines as raw coal avoids the need for settling tanks and attendant slurry problems.

Kimberly mine in the Jefferson seam was selected as the logical place for experimenting with a full scale plant on raw coal feed for the following reasons:

- Kimberly is a comparatively small mine having an output of 450 to 500 tons per day so that for an initial trial of this method, the installation could be made at the least expense.

- Additional washing capacity may be needed at Kimberly because plans are being made to increase the tonnage. It was hoped the cell plant would increase washer capacity.

- The jig at Kimberly is a Montgomery jig, a type of jig with a fixed screen under which a plunger with flap valves provides the jigging strokes and pumps the water required. Tests of the washed product indicated that jig separation became poor at —1/8 in. as compared with —35-mesh for the Baum type jig.

- The fines in the Kimberly washed coal were found to be quite high in ash so that if raw coal flotation was successful, an overall reduction of 3 pct could be expected in ash content of the washed coal from this mine. Such reduction would give a greater return per dollar of invested capital than could be obtained at the other mines.

Under present operating conditions, the flotation plant receives a feed of about 12 tph of —10-mesh coal of about 23 pct ash at a pulp density of between 15 and 20 pct. It delivers about 7¾ tons of floated coal assaying 5 pct ash, returns ½ ton of unfloated material to the jig at about 30 pct ash, and sends 3¾ tons of refuse containing 58 pct ash to waste.

Flotation of raw coal feed has proved quite successful and the advantages that were expected to result from this method have been realized.

- Retention of fine coal. Wasting the hutch discharge is the method used at Kimberly to bleed water from the circulating system. Prior to the installation of the flotation units, the hutch discharge from the jig assayed 36 pct ash, indicating a loss of coal roughly estimated at 6 tons per day. The hutch material is now about one tenth the former quantity with an ash content of about 51 pct, representing a negligible loss.

- Greater capacity on the jig. After installation of flotation, the elevator conveying the washed jig product was speeded up approximately 20 pct and a further increase in speed is contemplated.

- Better jig performance. Prior to flotation the ash in the jig refuse averaged 66 pct and the float at 1.45 sp gr in the jig refuse, 4.8 pct. Now the jig refuse ash is 70 pct and the float in the refuse 3.8 pct.

Cell Capacity

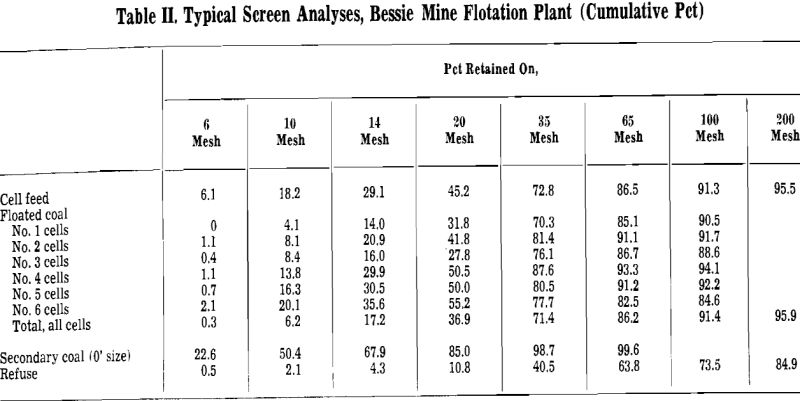

The capacity of a flotation unit depends on many factors among which are pulp density and the permissible loss of values in the rejected material. In the Sloss units, the pulp density decreases from cell to cell as floated coal is removed, and the amount of coal floated per cell also decreases. To avoid appreciable loss of coal in the refuse, experience indicates that the amount of coal floated in the last cell should not exceed 1 tph for a 100 cu ft cell or ½ tph for a 50-cu ft cell.

The distribution of floated coal by cells varies with loading and other factors. Two typical examples of distribution with normal loading as determined by test are given here.

At Bessie, with the float from the first cell taken as unity, the float from the second cell was found to be 0.80; from the third cell, 0.37; from the fourth cell, 0.33; from the fifth cell, 0.15; and from the sixth cell, 0.11. Likewise at Kimberly, with the float from the first cell as unity, the float from the second was found to be 0.98; from the third, 0.96; from the fourth, 0.78; from the fifth, 0.50; and from the sixth, 0.40.

Reagent

The reagent used at both Bessie and Kimberly at the present time is kerosene with no additions. All of the original experimental work was done with a mixture of about 93 pct kerosene and 7 pct B23 frother as reagent. The Bessie installation was started using this same mixture.

After the Kimberly plant was in operation, several brief snap sample tests under the supervision of Gandrud and Riley were made using both pine oil and B23 as an addition. These tests gave improved results when pine oil was added and still greater improvement when B23 was added. Except for these brief test interludes, only straight kerosene without additions has been used as reagent at Kimberly. With the present rate of feed, the cell operating results have been considered satisfactory. Should an attempt be made to increase capacity, the use of additions to the kerosene probably would be considered again.

Dewatering

One of the advantages of the kerosene flotation process is that the floated coal can be readily dewatered to about 25 pct moisture by the use of a very simple device, the dewatering screw. This device is described in detail by Gandrud and Riley. In the Sloss installations, this advantage has not been fully developed because moisture reduction to this extent has not been needed. At Bessie the moisture content of the coal as discharged from the screw varies from 34 to 45 pct with an average of about 37 pct; at Kimberly, from 44 to 52 pct with an average of about 47 pct.