In general, the beneficiation of sand and gravel consists of the removal of certain low specific gravity deleterious particles from the sand and gravel. These particles are coal, lignite, ochre, chert, sandstone, wood, clay, shale, and chalk. These deleterious materials almost always have an apparent specific gravity which is less than 2.35 while good sand and gravel has an apparent specific gravity of 2.6 to 2.75. There are instances where some of these deleterious materials have a specific gravity near that of good gravel, but fortunately, this is not the general case.

When it became apparent that the beneficiation of sand and gravel was necessary some ten or twelve years ago, it was quite natural for the manufacturers of sand and gravel equipment to turn to the coal and ore mining industries where beneficiation was already in common use. In observing their equipment and technique, it was apparent that the beneficiation process of sand and gravel is different from that of coal and iron ore. The percentages of deleterious material to be moved from the good coal and iron ore run higher than those of sand, and gravel. This actually makes the beneficiation of sand and gravel a more difficult process. The coal industry waste is high specific gravity material, while the waste in the iron ore and sand and gravel industries is low specific gravity material. There were several considerations which led to the choice of this particular machine. Sand and gravel is a low-priced, commodity, much lower in price than either coal or iron ore, and this diaphragm jig having low initial, operating, and maintenance costs was adaptable. Water is the liquid used by this particular machine, and since water is generally available at sand and gravel plants, this diaphragm jig was adaptable. Experiments at the iron mine indicated that since this Jig could make a cut between low specific gravity particles and those of high specific gravity, it would be adaptable to sand and gravel.

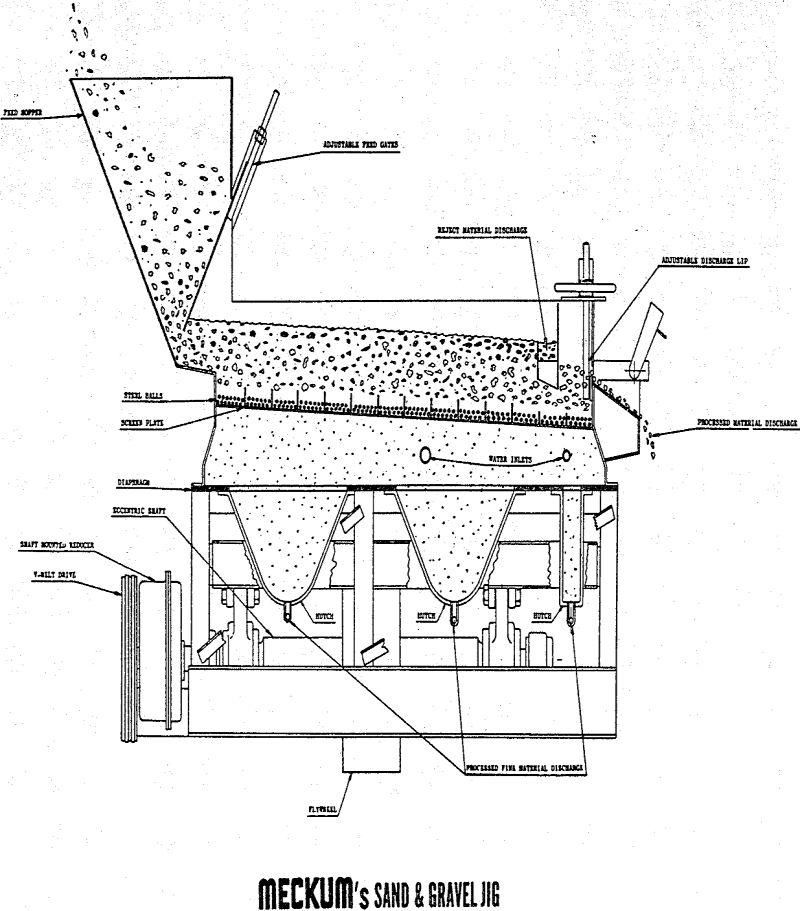

In general, the term “Jig” applies to a machine for the classifying of materials by their respective specific gravities or unit weights, by means of a pulsation of a liquid, generally, water, flowing alternately upward and downward through a bed of the material. This liquid passing through the material pulsates or jigs up and down the complete bed of material causing the heavy or highest specific gravity particles called “Sink Material,” to work downward to the bottom of the bed, and the lightest or lowest specific gravity particles, called “Float Material,” to arise to the top of the bed. The two materials, Sink and Float, are then drawn off separately.

Generally, the percentage of deleterious material to be removed from a sand and gravel deposit runs from 3% to 8% and the jig usually removes above 30% of this material. The jig can remove higher percentages and has done so, but the efficiency of the operation may go downward.