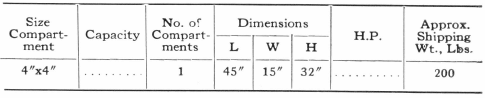

Table of Contents

Harz Type Jig

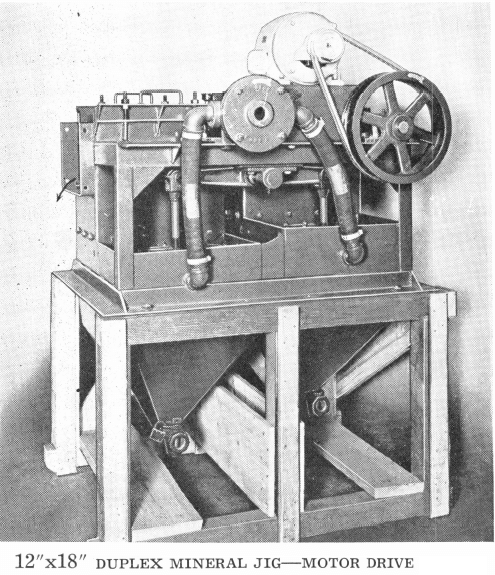

The (Improved Harz Type) Jig is essentially a coarse – mineral Jig Concentrator embodying improvements on the Harz Jig and the Ellis Jig. It will handle successfully all types of ores which can be treated by gravity concentration with feed size ranging from ¼” to 1½”.

These jigs are made in three sizes and with one to six compartments subdivided by a shallow partition into a screen compartment and a plunger compartment. Reciprocation of the plunger causes flow of water through the screen. The coarse and heaviest particles settle onto the screen and are removed by a side drawoff. The heavy fine particles pass through openings in screen into hopper-shaped hutch, from which they are discharged intermittently or continuously. The light particles pass into next compartment where currents are of lower velocity.

Standard construction is tanks and frames made of kiln-dried Douglas fir and laminated wood plungers. Iron work consists of necessary tie rods, eccentrics, plunger rods, screens, concentrate draw offs, shafting and bearings. Tanks may be welded steel plate. Jig may have belt or motor drive.

Additional data gladly furnished upon request.

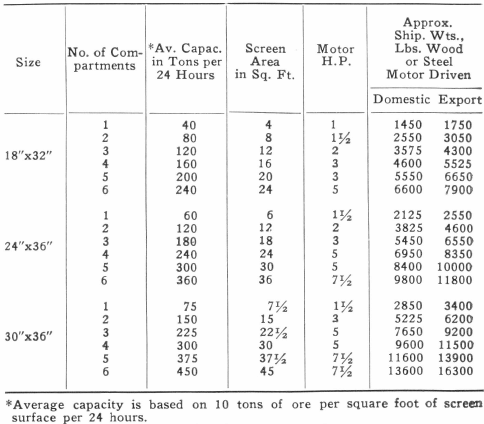

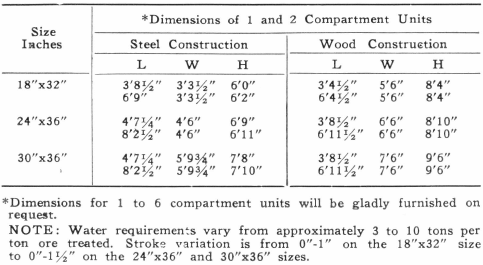

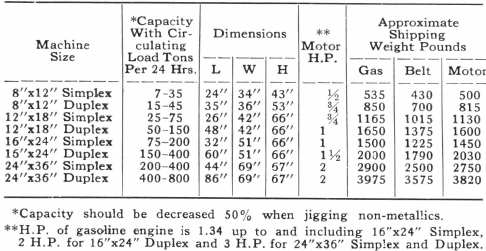

Jig Concentrator Capacity

Selective Mineral Jig Concentrators

Mineral Jig is not just another jig. It is a highly efficient selective pulsator and concentrating machine, which has the ability to treat an unclassified feed . . . separating solids having only a slight differential in settling rates, with only a minimum addition of water. It is successfully used on practically every type of ore. Gold, lead, zinc, copper, native copper, nickel, iron, manganese, tungsten, chromite, and fluorspar are a few of the ores which can be concentrated in this jig.

The Mineral Jig is usually installed in the grinding circuit between the ball mill and classifier, or at any other point in the circuit where free mineral is present. It is ideal for use in cyanide, flotation, and gravity-concentration mills; base-metal and nonmetallic mills; tungsten- gold mills; and placer operation; to save minerals as coarse and as soon as possible, thus reducing grinding cost.

This jig is simple to regulate and control, requiring only periodic discharging of concentrates from the hutch, which can be locked to prevent theft of high-grade mineral, or can be arranged for continuous discharge by using a Dowsett Density Control Valve. The Mineral Jig requires a minimum of attendance; dilution is easily controlled, as it is always necessary to add water to the jig tailing for subsequent classification. It requires minimum floor space—being less than that for any other concentration unit; and has a low initial cost. No pumps or elevators are needed in the ball-classifier circuit, as the jig acts as a launder. It treats an unscreened, unclassified feed—yielding a clean, high-grade concentrate. The distinctive upper trash screen prevents foreign tramp matter from interfering with normal jig operation, and the lower wedge-bar screen minimizes the blinding so common in other jigs. The rugged design of the jig with its few wearing parts insures continuous “24 Hour Service.”

Jig Concentrator Capacity

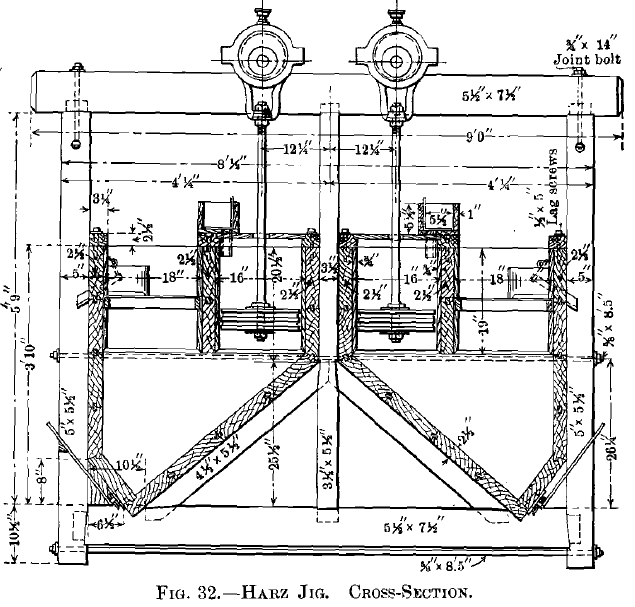

Harz Jigs differ in principle from all those previously described, inasmuch as the particles are separated by their fall through a somewhat deeper column of water than is the case on inclined tables, while a series of blows from below, causing waves moving upwards, continually brings the particles into suspension, and allows them to drop again. The initial period of the fall in water, during which the motion depends chiefly on density, is thus continually reproduced, and the result is a perfect separation of heavy from light particles of ore when working on any materials except the finest pulp. Jigs consist of sieves supporting beds of ore, which are completely immersed in water ; the ore is raised and allowed to fall by a quick succession of currents of water caused by the sudden action of a piston below, which is so worked that the upward movement or pulsation resembles that produced by a blow, while the downward movement is gradual. Under these conditions the heavy particles work downwards and pass through the sieve, while the lighter gangue is carried away horizontally by a stream of water introduced either from below or from above. Such machines are especially suitable for coarse ores.

In the Harz jig a layer of coarse heavy particles is spread on the sieve to prevent too much of the ore from passing through. The stuff is fed in regularly at the head of the jig, and the strokes of the piston raise both the bed of heavy particles and the ore. The heaviest grains of ore find their way during the downstroke into the interstices of the bed, gradually pass through it, and coming to the screen, fall through into the tank below. The lighter particles cannot descend, and are gradually washed over the end partition by the continuous supply of water. Two products are therefore given, neither requiring further treatment if the conditions are favourable, and the machine properly adjusted. The wire meshes of the screen are always much larger than the ore treated, and the bed is composed of material of as nearly as possible the same density as the concentrates to be obtained, and is usually from ½ to 1 inch in depth. The number of strokes of the piston per minute is from 60 to 80 with coarse sand of 1/12 inch in diameter, and 200, 300, or even 400 with very fine sand, approaching slimes. The length of stroke varies under the same conditions from 2/5 to 1/5 inch, and in the case of very fine, almost impalpable sand, the stroke may be diminished till it becomes a mere tremor. Some of the highest authorities on concentration have stated their belief that for enriching even very fine sand, the Hartz jig is the simplest and most economical machine yet invented, and requires the least amount of labour.

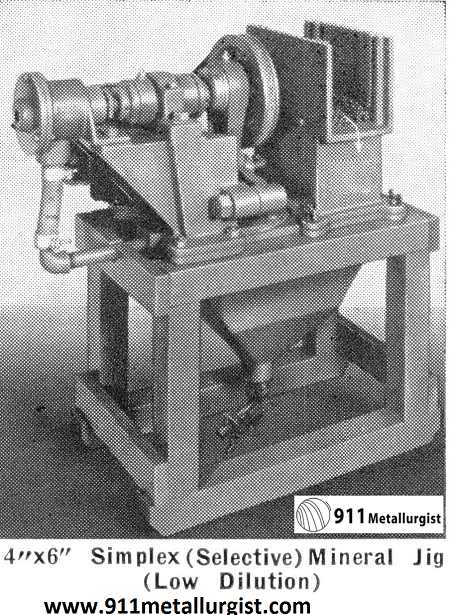

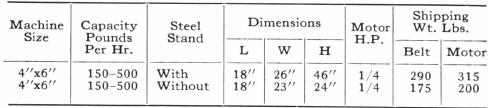

Selective 4″x 6″ Mineral Jig Concentrators

Mineral Jig, size 4″ x 6″, is a unit which fills the needs between the 8″x 12″ Simplex Mineral Jig and the No. 1-M Laboratory Jig, due to its applicability to both commercial and test work.

Although the 4″ x 6″ Mineral Jig is ideal for many uses in commercial work, it also has considerable merit as a unit for use in pilot mill operation and in large batch laboratory tests. It is suited for non-metallic or open-circuit work in the laboratory especially where a large quantity of concentrate must be obtained. This size jig is most desirable for trial installation in large tonnage mills to determine the desirability of a jig in the circuit, as it can operate on small quantities of material of the same size as that handled by the larger size jigs.

The 4″x 6″ jig has a single hutch compartment and a reversible screen compartment constructed of cast iron so that cyanide solutions can be fed to the unit instead of water if desired. The rotating water valve is timed to admit water only on the plunger up-stroke and is located on the end of the eccentric shaft. The eccentric shaft is mounted in a ball-bearing double-pillow-block type bearing. An adjustable eccentric is used for varying the movement of the rubber diaphragm. The upper trash screen consists of a four mesh woven-wire cloth. Two lower wedge-bar screens are furnished with each jig; one with 2-millimeter openings and the other with 5-millimeter openings.

When the jig is used on continuous tests, a steel stand is recommended for mounting the jig. The steel stand is arranged with a shelf for holding a glass jar which accumulates the jig concentrate as it discharges from the hutch and which facilitates the inspection of the type of jig product while the test is being conducted.

Jig Capacity

Jig Capacity

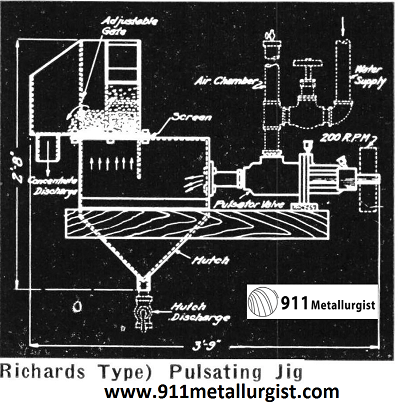

Richards Type Pulsating Concentrating Jig

The (Richards Type) Pulsating Jig concentrates ore too coarse for treatment on concentrating tables. It is similar to the ordinary plunger type of jig except that the plunger action is supplanted by a pulsating water current. By this means the screen surface has a much greater capacity than that of the ordinary jig. As there is no suction stroke, and the pulsating current is always upward, there is no clogging of the screen. A high grade mineral product is made which is drawn from the hutch. This jig is made in various sizes. Its water consumption is greater than the (Selective) Mineral Jig.

Jig Concentrator Capacity