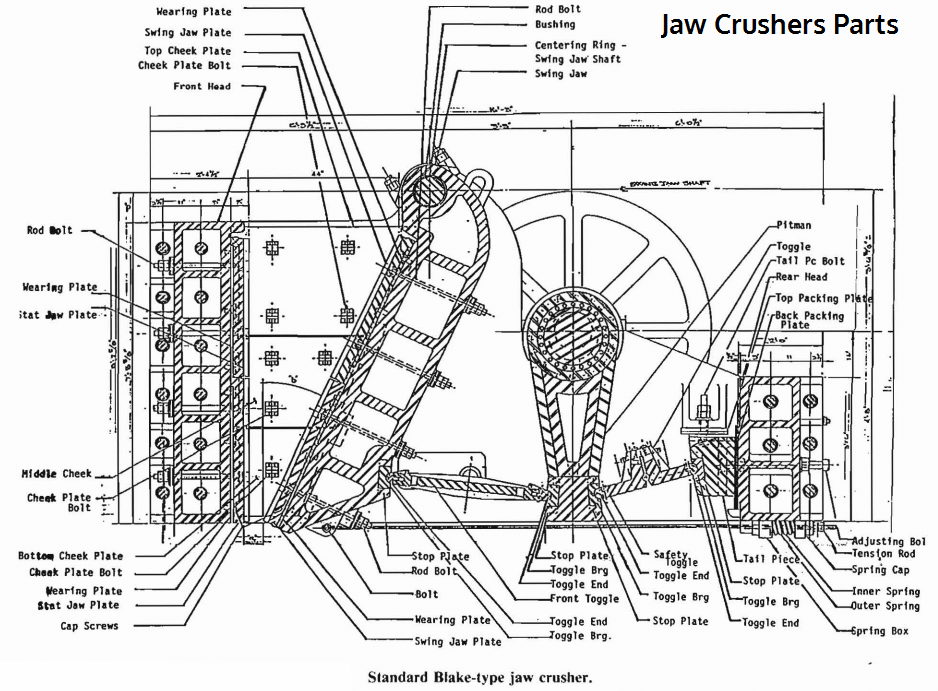

Although the jaws do the work, the real heart of the jaw crusher and its components are the toggle plates, the pitman, and the ply wheel.

These are the parts and components that generate the crushing action and provide the energy needed to break the ore. Let’s follow the chain of events within a crushing cycle to see how they all go together. The first component of the crusher is the drive motor. This will drive a reducer sheave that is attached to an eccentric shaft. On the other end of the shaft is the flywheel.

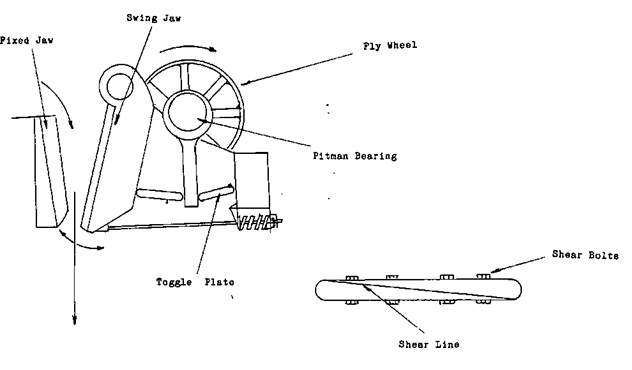

The purpose of the flywheel is to generate energy in the form of motion. Once the motor has the flywheel turning the momentum of the wheel will carry it through a crushing cycle. The motor then will only have to provide the energy necessary to propel the fly wheel.

That is where the energy comes from, the crushing action itself is generated by the eccentric shaft, and this shaft is called the pitman. This is simply a shaft with a portion of its length offset from the rest of the shaft. As the shaft is revolved that portion will travel in a greater arc. By attaching a bearing system called the pitman bearing and cap to it is possible to generate a motion whose direction is primarily up and down.

There is an arm extending from the pitman that the toggle plates sit in. The toggle plates are set at an angle to the arm and the swing jaw. As the pitman is revolved the arm is pulled up. This causes the toggle plates to come to the horizontal position. The movement of the toggle plate forces the swing jaw to be pushed outwards towards the stationary jaw thus crushing the ore.

Depending upon the make of Jaw crusher the Toggle plates may provide another very important function. With some designs the toggle plates are made up of two steel plates that are bolted together with what is known as SHEAR BOLTS. These are bolts that have a known shear strength. If something that the crusher cannot crush accidentally gets into the crushing chamber these bolts will shear off when the Jaw hits the unbreakable object. This will prevent damage to the rest of the crusher.

Unlike the gyratory crusher the main lubrication used on Jaw crushers is grease instead of oil. In using grease there may be several different ways that it will be fed to the necessary lubrication points. It could be manually with a grease gun. Or possibly grease pots or metering pump will be the system used. Whichever it is, the bearings will be a critical portion of the operator’s circuit checks.