hile particle size is universally acknowledged to be important in optimizing industrial copper sulfide rougher flotation circuits, many of the various interactions that do occur at the industrial level with particle size are still being identified and/or quantified.

In order to quantify the data collected, a simple two parameter model for fitting time-recovery data will be used:

r = R[1-(1/(Kt))(1-exp(-Kt))]

where r is cumulative recovery at time t (or at cell number t), R is the long-term equilibrium recovery, and K is the first-order rate of mass removal from the cell (time-¹).

Test Sequence

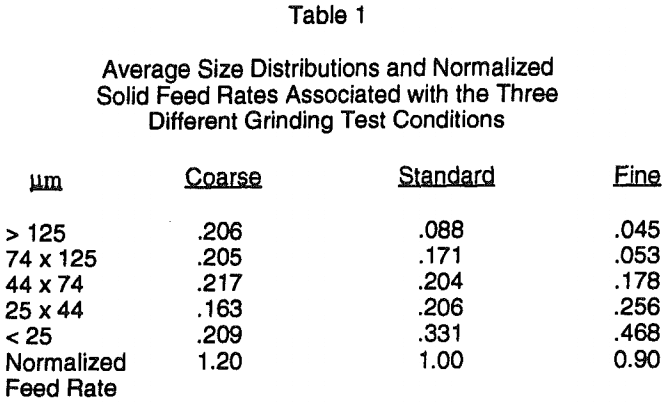

A substantial quantity of chalcopyrite containing copper sulfide ore of head grade, 1.01 % Cu, was isolated for use in specific rougher bank tests. The feed rates were chosen so as to give approximately constant copper production with varying grind conditions. The collector was potassium aryl xanthate (PAX) with dosages of 10, 20, 30,40, and 50 grams/ton of dry feed and the pH in all tests was 9.5, adjusted by the use of lime. The three frothers used were DOWFROTH 250 (used totally or partially in all tests run), and DOWFROTH 200 or DOWFROTH 1012 as a blending constituent in selected tests.

The choice of PAX as the collector of choice and DOWFROTH 250 as the frother of choice was based on previous plant experience and the fact that similar industrial processed ores to the particular ore of this study responded well to the PAX/DOWFROTH 250 combination.

Results

Inspection results leads to a number of conclusions: 1) all of the recovery curves demonstrate some type of maximum with regard to collector dosage; 2) despite the lower recovery associated with the coarse grind (and hence higher feed rate).

With the coarse grind and higher feed rate (a fact well known to Western Hemisphere copper sulfide flotation plant operations); 3) using only the DOWFROTH 250 frother, there is a consistent shift in what collector dosage is optimal for each grind condition (as the grind gets coarser, the optimal collector dosage required for maximum recovery gets larger), and 4) the use of appropriate frother blends for either the fine size feed or the coarse size feed eliminates much of the recovery drop-off (the R/K trade-off) being experienced with the higher collector dosages using DOWFROTH 250 only (as evidenced by a shift upward in the recovery curve at any collector dosage and also a shift in the maximum recovery to a higher collector dosage).

It is clear that increases in dosage from 10 to 30 grams is only necessary for the two coarser size fractions and at 40 grams, the recovery of the coarse sizes starts to decrease. The associated rate constants for each size all seem to go through a maximum near 30 grams except for the very finest sizes which are still increasing in rate with dosage. This is a nice example of the R/K trade-off in industrial practice. For the four largest size intervals, the rate clearly goes through a maximum with increasing collector dosage, yet only the two largest sizes show a drop-off in measured final rougher bank recovery at the highest collector dosage.

The addition of some coarser particle frother clearly has the effect of increasing the measured rougher bank recoveries of all sizes but especially of the two coarsest size fractions. It is doing this by moving the R/K trade-off in rate to a higher collector dosage (40 grams for the coarsest size and 50 grams for the next coarsest size as compared to 30 grams for the same two sizes).

The following trends appear to be valid with regard to the interaction of grind size, collector dosage, frother type in the industrial scale rougher flotation of chalcopyrite ore. For an approximately constant production of copper with varying feed size (and hence varying feed rate) the following has been observed:

- the R/K trade-off with increasing dosage is clearly an important industrial phenomena that influences, both the recovery and grade achievable in a given bank of cells;

- as the flotation feed stream gets increasingly finer, the collector dosage corresponding to the maximum recovery gets increasingly smaller;