Table of Contents

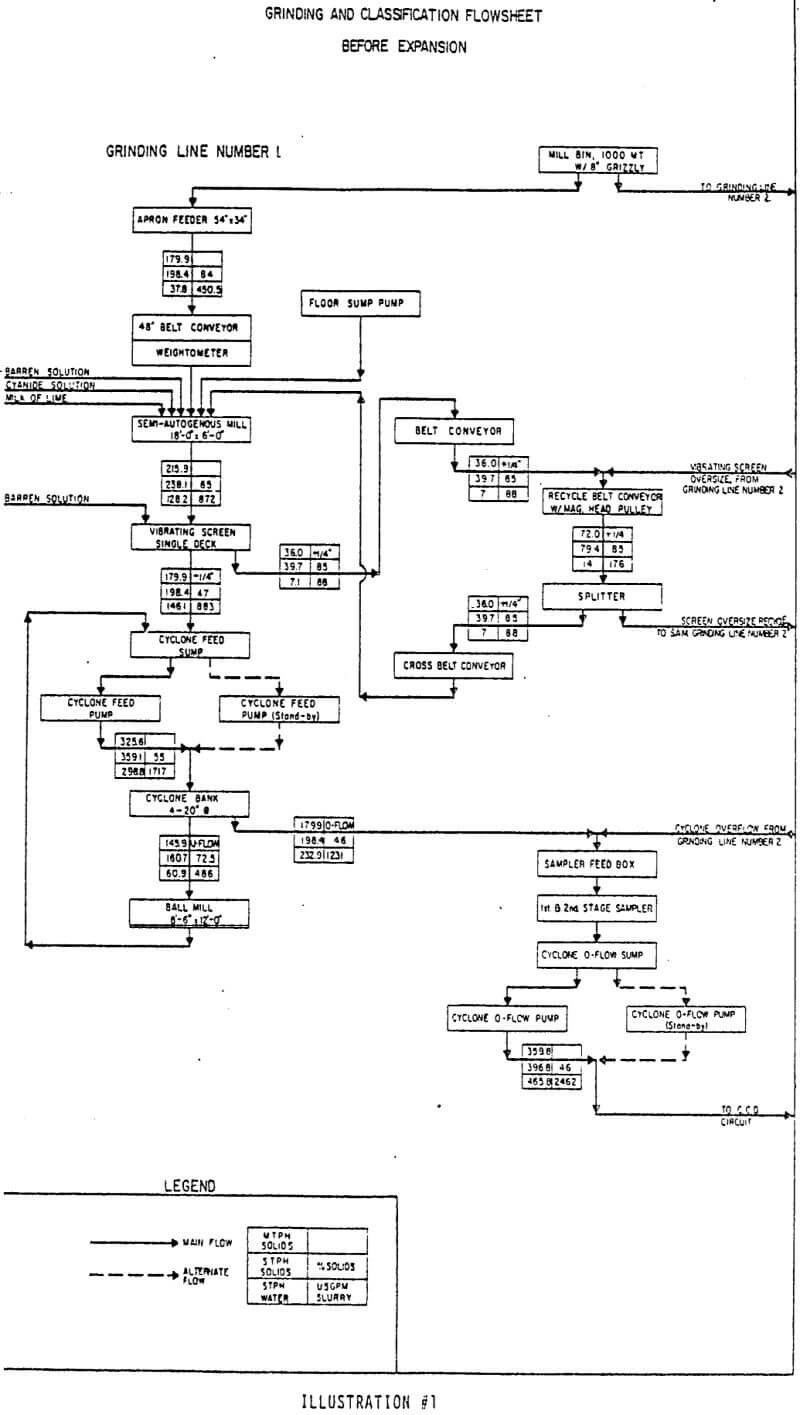

Shortly after start-up, it was apparent that it would be difficult to obtain the plant design throughput. The ore sample that had been used for grinding test work was found to be much softer than that of the orebody in depth. This had led the designers to design without a crushing stage and to designate the primary semi-autogenous mills as scrubbers rather than mills. On start-up, it was found that the ore was much tougher and less sticky than specified in the design criteria. In the initial months of operation, it was necessary to selectively mine softer ore from the west flank of the orebody to obtain the mill design throughput.

Gradually, with minor plant modifications and by running the semi-autogenous mills 50% in excess of design power draw (680 kw instead of 450 kw) and by milling to a coarser grind than recommended by the thickener manufacturer (30% + 65 mesh instead of 20% + 65 mesh), plant design throughput was obtained with ores of typical hardness. The minor modifications made centered principally on the semi-autogenous mills where the grate openings were changed from 22.2 mm to 50.8 mm; the ball load from a mixture of 102 and 76 mm balls to one of 127 and 102 mm balls; the mill drive motors rewound to change the power rating from 450 to 600 kw and to allow operation at a higher temperature, and cooler/blowers installed for forced ventilation of the motors. Other modifications consisted of opening the apertures of the apron feeders to allow a higher maximum tonnage; changing the cyclone feed pumps to larger, slower rotation units; and changing the cyclone feed pump drive motors from 40 to 75 kw. At the thickeners, the rake drives were speeded up from 0.033 to 0.039 rpm and the drive motors of one of the two underflow pumps of each thickener changed from 30 to 55 kw.

However, maintaining plant tonnage at the design rate, required deliberate operation at a continuous crisis point. Problem areas were:

- About 4% of run-of-mine ore was coarser than the 41 cm square openings- grizzleys at the truck dump points. This required continuous scraping of oversize rocks off the grizzleys.

- Semi-autogenous mill main drive speed reducers failed regularly (about twice/ year/mill line).

- Semi-autogenous mill drive pinions spalled badly requiring replacement about once/year.

- Semi-autogenous mill trunnion bearings failed occasionally (usually the discharge end bearing about once/year).

- Leach tanks overflowed because of accumulation of coarse sands.

- Thickener drives were almost continuously overloaded and pumping systems frequently plugged. Thickener drives tripped out on occasion (about 4 times/year).

- The tailings line sanded up frequently (about once/month).

Concurrent with the plant operation difficulties, it appeared that the company would be granted the right to mine an orebody it had discovered on the adjoining Los Cacaos concession. One of the requisites to the granting of the concession would be an expansion of mill capacity. It became apparent that a plant expansion could both resolve operational problems and provide an opportunity of expanding throughput.

Mill Expansion Objectives

The operational problems were symptomatic of three factors which were:

- No primary crusher incorporated in the plant design.

- Deliberate overloading of the semi-autogenous mill drives.

- Grinding plant product too coarse.

Objectives for the resolution of the plant problems and the incorporation of an expansion in capacity were outlined. These were as follows:

- Install a large crusher capable of crushing run of mine ore down to 25 cm to eliminate scraping oversize off the grizzleys and reduce secondary blasting.

- Replace the existing drives and lubrication systems of the semi-autogenous mills for continuous duty at 750 kw.

- Add additional grinding capacity or install a desanding plant.

The first two objectives presented relatively straightforward answers. To realize the crushing objective, a large (1½ m x 1½ m) jaw crusher was purchased and installed. Rosario Dominicans personnel constructed the facility from drawings prepared by an engineering company in the U.S.A. For the semi-autogenous mills new motors, gear-boxes and mill drive pinions rated at the required 750 kw were ordered and new continuous high capacity high and low pressure lubrication pumps were installed.

Expansion Effects of Downstream Equipment

It was evident from prior operation of the plant at high tonnage (when milling extremely soft ore) that the equipment downstream of the mills had adequate capacity to handle the increased throughput but additional care would be required in the thickener operation. To keep the thickener operation under control at the increased tonnage, some form of continuous pulp/solution interface monitoring device may be needed and the possibility of installing higher duty rake drive mechanisms is being considered.

Since the solution circuit was already operated at maximum capacity of 250 l/s and would require substantial additional equipment to operate at a higher throughput, it was decided to leave the system unchanged. The higher mill tonnage of the expansion would result in a lower wash ratio (solution tonnage/ ore tonnage) and thus solution losses to tails would be slightly higher than previously, but since tails solution is reclaimed, there would be a negligible change in recovery.

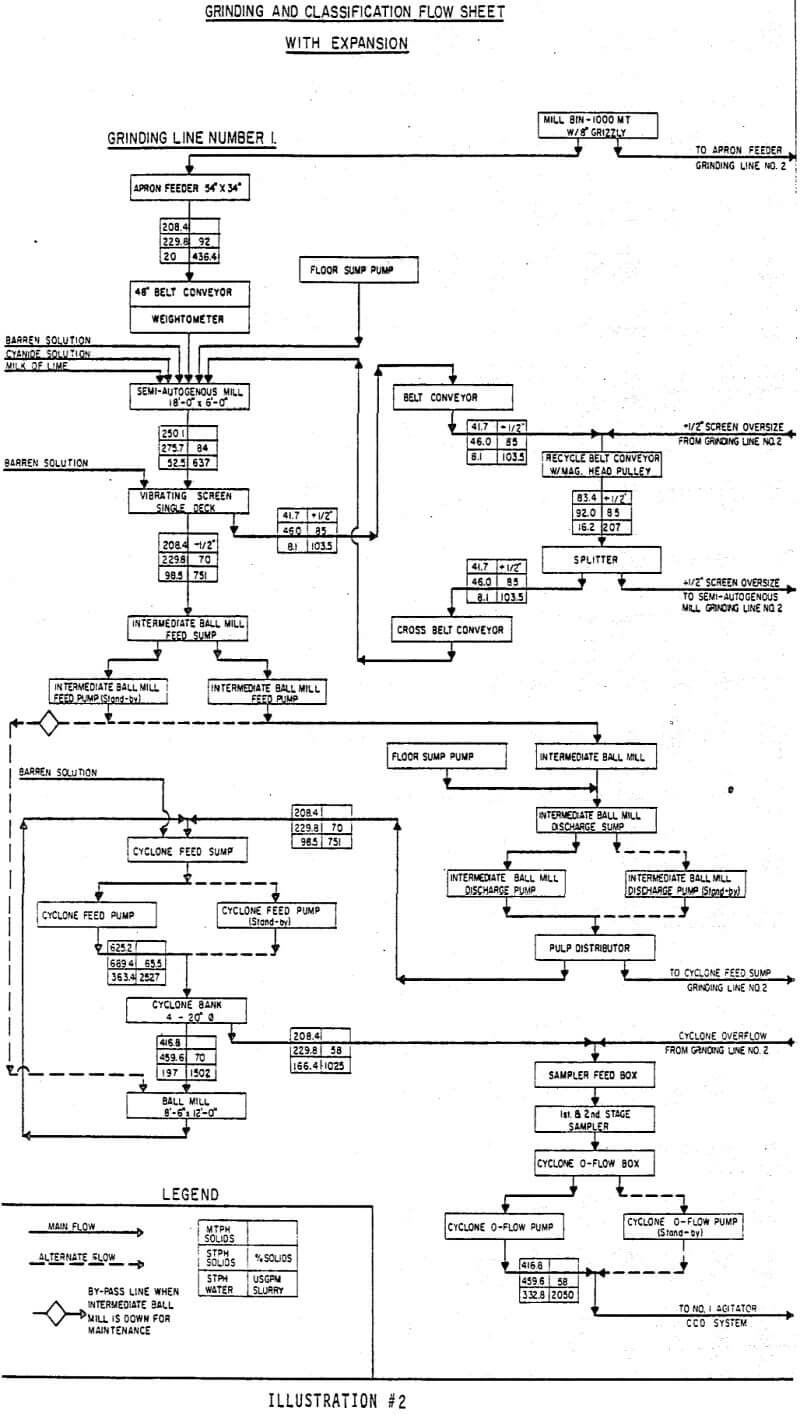

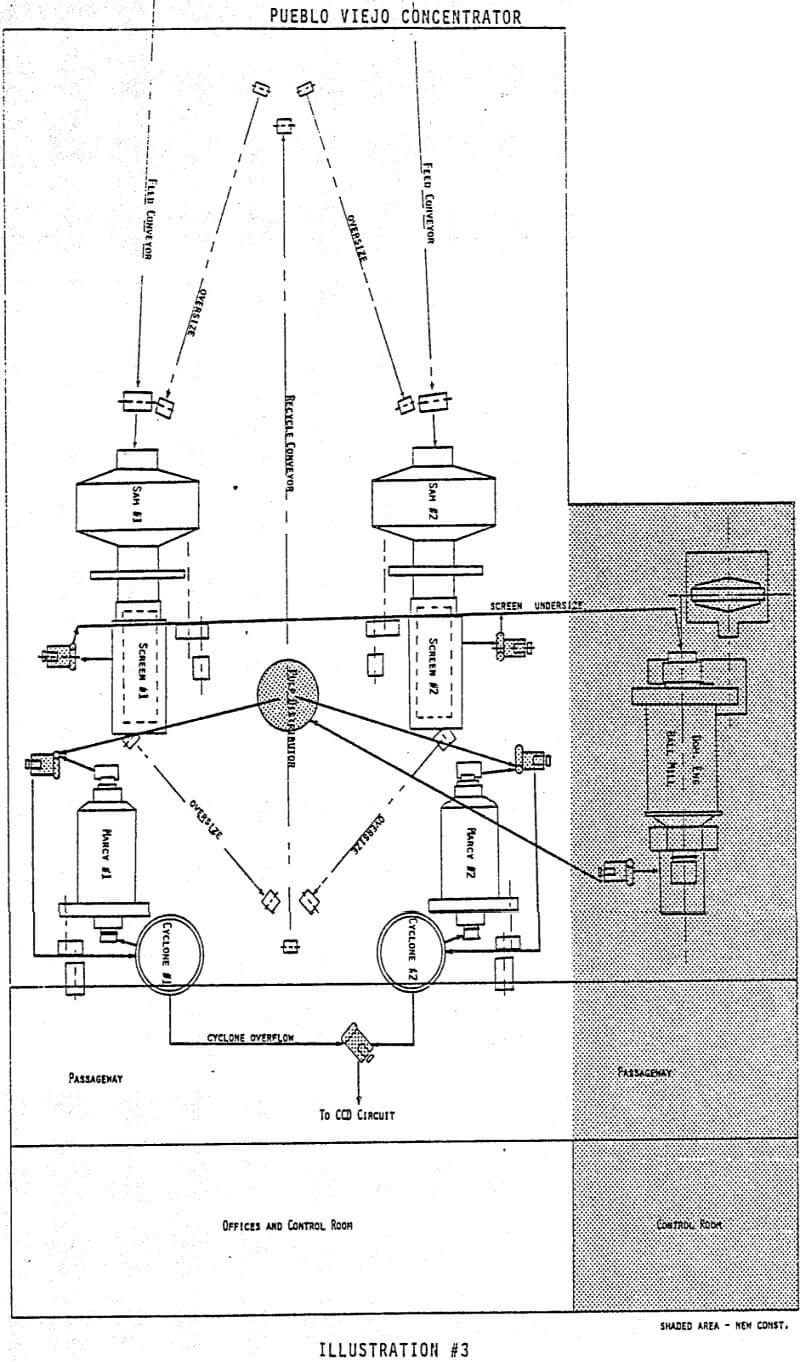

The second alternative, providing increased throughput by grinding plant expansion, offered a more rational method of obtaining additional capacity. It permits utilization of the existent straight-forward plant configuration without major changes. It also provides a better guarantee of increased mill throughput than would the desanding plant.

It was decided to add approximately 1,000 horsepower of additional grinding capacity to the grinding system at some point following the primary grinding circuit. An opportunity presented itself to purchase a second-hand 3.25 meter diameter by 4.25 meters long Dominion ball mill. Since deliveries on new equipment would have required considerable delay in effecting the expansion objectives, a decision was made to acquire this mill and ship it immediately to the Dominican Republic.

It became apparent that the bottleneck in the existing grinding circuit was in the primary grinding and screening section. This section had originally been designed to operate in a virtual scrubbing capacity to handle extremely soft ore which required very little primary grinding. These mills were originally intended to operate with about 2% by volume of steel grinding balls. After the mine was opened up, it became apparent that the feed to these mills would not be the extremely soft material anticipated and in many cases, extremely hard ore would be fed from sections of the pit. Subsequently, steel grinding media eventually reached approximately 12% by volume in the primary mills.