Table of Contents

The experimental results appear to support two principal conclusions: First, the three natural and three synthetic slurries tested all exhibited individual filtration characteristics and individual flocculation properties; moreover, their behavior was not related directly to either size composition or ash content. Thus each slurry must be evaluated individually in predicting the possible benefits of fIocculation. Substantially the same conclusion was reached by Meerman, whose investigation was on a full plant scale.

Second, some of the newer flocculants are so effective that only a few thousandths of a pound per ton are needed, but with several of the slurries examined the performance obtained did not exceed that possible with greater amounts of starch.

Introduction and Summary

Traditionally, fine coal is more troublesome than the coarser sizes at every step of the coal-preparation process screening, cleaning, dewatering, and drying. Therefore the present trend toward a higher proportion of fines in the run-of-mine product, brought about by changes in mining practice necessitated to increase productivity, has added greatly to the task of preparing coal for the market. One of the more difficult and costly problems involved is that of recovering fine solids from the washery water. These fine solids should be recovered in the interest of conservation, and they must be removed to provide recirculating water of proper quality. If there is a plant effluent, it must meet increasingly stringent requirements against stream pollution.

Vacuum filtration has been used for years at a few plants to recover the extreme fines, but its additional cost discouraged general adoption until recently. Now, with growing emphasis on better solids recovery, filtration is becoming more widespread. Many coal slurries filter readily, giving high cake rates and clean filtrates. Others, however, particularly those containing either a high proportion of material finer than 200-mesh or an appreciable amount of clay, are much more difficult to filter. Many of these refractory slurries can be rendered more filterable by flocculation. A previous report of Bureau of Mines research dealing with flocculation alone was published in 1940.

Lime and starch (the latter either plain or causticized) have been used as flocculants by the coal industry for years to increase the settling rate of coal slurry and thus improve the capacity of thickeners. These flocculants are now being used to improve the filtration characteristics of some slurries. Recently, a host of new flocculants has been made available. They are primarily synthetic polymers or gums, and with some of them very small quantities are extremely effective.

The threefold objective of the present investigation was to determine: (1) How the newer flocculants compared with lime and starch in improving filterability, (2) to what extent slurries of different composition could be improved through fiocculation, and (3) why some slurries are much more difficult to filter than others. The scope of the investigation embraced 3 natural slurries, 3 synthetic slurries or suspensions, and 16 flocculants. A standard test-leaf filter was the principal tool used to evaluate filterability, but confirming tests were made with a laboratory-size disk filter.

One of the slurries examined contained comparatively little clay, was not excessively fine, and therefore filtered quite readily without fIocculation. However, even with this slurry a marked increase in cake rate and a substantial improvement in filtrate quality were obtained by flocculation. The other two natural slurries contained more clay and therefore showed greater benefit from fIocculation. An increase in cake rate from only 18 to over 100 pounds per square foot per hour and a concurrent improvement in filtrate quality were obtained with the most refractory of these three slurries.

Filtration of synthetic slurries to which various types of clay were added as contaminants demonstrated that bentonitic clays, particularly those containing sodium montmorillonite, were much more detrimental than kaolinitic clay.

The individual flocculants exhibited a wide range in effectiveness; and, although some of them were consistently superior with all slurries tested, no one flocculant was universally the best. Some of the newer flocculants were so effective that only a few thousandths of a pound per ton of solids was needed, but in most instances their performance did not exceed that possible with larger amounts of starch.

Description of Slurries

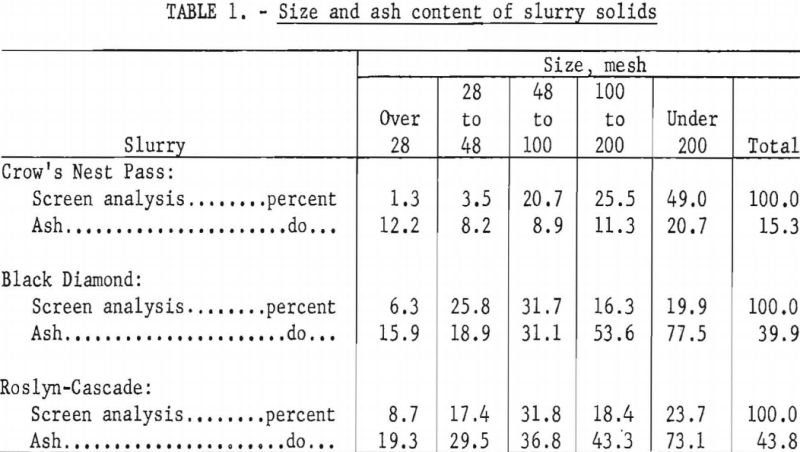

The first of these, the Crow’s Nest Pass slurry, was the thickener feed from the washed-coal section of the Michel colliery of the Crow’s Nest Pass Company, Ltd., Michel, B. C. As shown by the screen and ash analyses in table 1, this slurry was virtually all finer than 28-mesh, with approximately half of the solids finer than 200. Substantially all the material coarser than 200-mesh was clean coal, but the ash content of 20.7 percent in the finest size indicates a moderate amount of impurity. This coal is medium-volatile bituminous in rank.

The Black Diamond slurry was obtained from the Black Diamond washery of the Palmer Coking Coal Company, King County, Wash. It was the underflow of a ½-mm. vibrating slurry screen and is a waste product that is discharged to a settling pond. As shown by the data in table 1, this slurry contained about 20 percent of material finer than 200-mesh, which analyzed 77.5 percent ash; this high ash content reflects the presence of a high proportion of clay. The coarser sizes were also high in ash because of the presence of bone and shale. The Black Diamond coal is on the dividing line between bituminous and subbituminous rank.

The Roslyn-Cascade slurry was from the washery of the Roslyn-Cascade Coal Company in Kittitas County, Wash. It was the underflow of a battery of 8-inch cyclones that is wasted with the coarser refuse from the plant. In both size and ash content it was similar to the Black Diamond slurry. However, being a cyclone underflow product, the fraction finer than 200-mesh undoubtedly contained a much smaller proportion of finely divided clay than was present in the Black Diamond slurry. The Roslyn-Cascade coal is high-volatile A bituminous in rank.

Initially the slurry samples were stored in the laboratory at a concentration of 40-percent solids. However, a progressive change in filtration and flocculation characteristics during storage was noted, presumably because of progressive disintegration of the clay. Careful testing demonstrated that the slurry solids could be dried and then repulped without changing the original filtration characteristics, provided they were soaked for 24 hours before use. Therefore new samples were obtained and stored dry.

Description of Flocculants

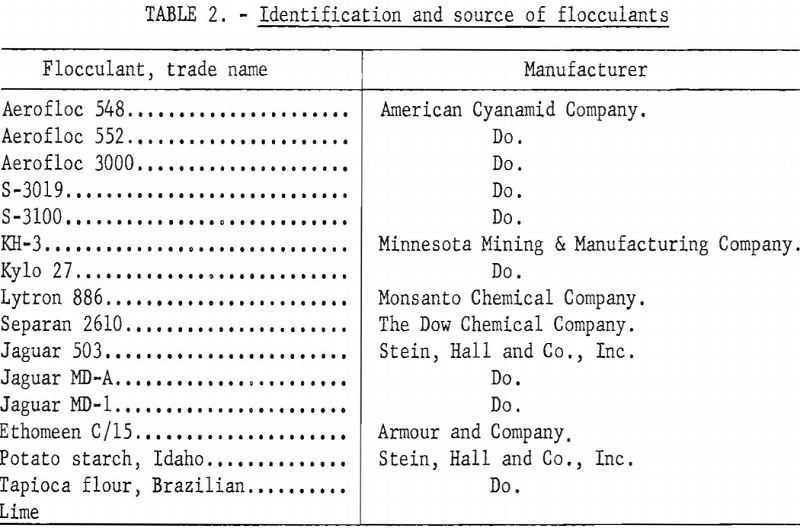

Table 2 shows the flocculants used. The first nine listed are classed as synthetic polymers; they are high-molecular-weight, water-soluble, organic compounds. The next three (the Jaguars) are gums; these reagents are the refined endosperms of the guar seed. Ethomeen C/15 is a surface-active agent of the amine type. The flour, starch, and lime were ordinary commercial products.

All synthetic polymers and gums were furnished in powder form and were prepared for use as solutions by adding the powder slowly to hot water with constant agitation. Separan 2610 was used as a 0.10-percent solution, whereas the rest of these flocculants were used as 0.50-percent solutions. Ethomeen C/15 was prepared by reacting with HCl in the proportion of 22.2 parts of acid to 100 parts of flocculant; it was then diluted with water to a 0.50-percent solution. The starch was prepared by mixing 1 gram with 19 ml. of water and then adding slowly, with constant agitation, 19 ml. of a 2.5-percent NaOH solution; after 15 minutes of additional mixing the solution was diluted to 0.50-percent strength.

Some flocculants are reported to deteriorate with age, so fresh solutions were prepared every few days.

Filtration with Test-Leaf Apparatus

Description of Apparatus and Test Procedure

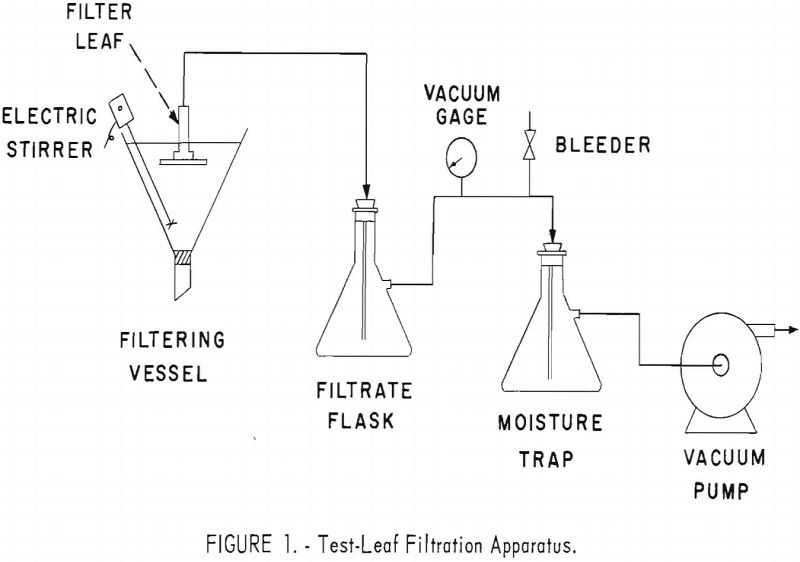

Figure 1 is a diagram of the filter-leaf apparatus employed. It consists of a test leaf having an effective area of 0.10 square foot, a 60°, 8-½-inch-diameter cone to hold the slurry sample, a variable-speed electric stirrer, a vacuum gage, a bleedline for controlling vacuum, a filtrate flask, a moisture trap, and a vacuum pump.

Two monofilament filter cloths were selected-Saran SA-603, which is coarse, and polyethylene PO-801 HF, which is fine. The Saran was picked to provide maximum cake rate without regard to clarity of filtrate, and the polyethylene was chosen to provide the best quality of filtrate, without regard to cake rate.

The test charge for the filtering vessel consisted of 800 grams of solids soaked for 24 hours in 1,200 grams of water, giving a standard solids concentration of 40 percent. The desired amount of flocculant was added and the mixture stirred for 2 minutes. The vacuum was then turned on and the test leaf immersed in the funnel to just cover the face of the leaf. As filtration commenced the vacuum was adjusted and maintained at 25 inches of mercury. The filtration cycle used consisted of 0.80-minute form time, followed by 1.10 minutes drying time. In conformity with the recommendations of the manufacturers of the reagents, virtually neutral tap water, pH 6.9, was used in all filtering trials.

Two filter runs designated as trials 1 and 2 were made. Trial 2 was obtained by returning the cake and filtrate of trial 1 to the funnel, remixing, and refiltering without the addition of more flocculant. In the case of the Crow’s Nest Pass slurry, the cloth was cleaned between trials, but with the other slurries it was not. Comparative tests showed that the reduction in cake rate generally obtained on the second trial was much the same, whether or not the cloth was cleaned between trials; consequently, the cleaning step was omitted for the Black Diamond and Roslyn-Cascade slurries. The wet-cake weight was determined after each trial, and the moisture content of the cake and the percentage of solids in the filtrate were determined after the second trial. The purpose of making the second trial was to provide a measure of floc strength; that is, to evaluate the extent of floc destruction caused by the remixing operation.

With a readily filterable slurry, one giving a dry cake rate exceeding 165 pounds per hour per square foot, the entire usable volume of slurry in the vessel was exhausted in less than the standard 0.80-minute form time; also, the standard vacuum could not be attained. With such slurries an adaptation of a formula advanced by Silverblatt and Dahlstrom was used to convert the data to the same basis as that for less filterable slurries. The equation is as follows:

R = 5720 (TV)-½

where

R = dry filter rate, in pounds per hour per square foot;

T = time required to filter charge, in seconds;

V = vacuum attained during time T, in inches Hg.

The cake rates obtained with this test procedure probably cannot be translated directly into rates for a commercial filter, but they provide comparative values that are useful in judging the effectiveness of flocculation.

Tests With Crow’s Nest Pass Slurry

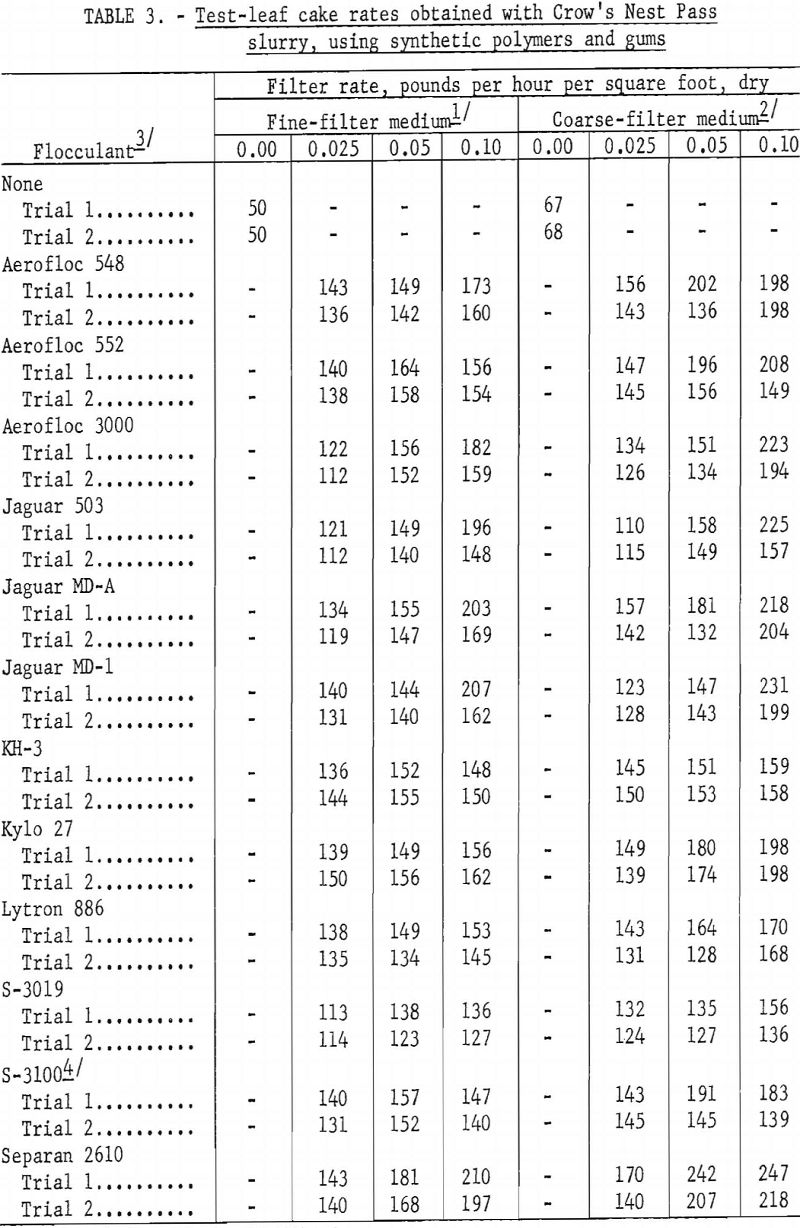

In untreated form the Crow’s Nest Pass slurry was readily filterable, giving cake rates of 50 and 67 pounds per square foot per hour with the fine and coarse cloths, respectively. Table 3 shows the cake rates obtained with the synthetic polymers and gums. The minimum addition of flocculant (0.025 pound per ton) produced a 2- to 3-fold increase in cake rate. Further increase in flocculant concentration resulted in only a moderate increase in cake rate, thus indicating that the slurry was well-flocculated even with the minimum addition. The insignificant difference in the cake rates for the first and second trials also is characteristic of a well-flocculated slurry; with good flocculation, the flocs generally are strong enough to resist disintegration. All of these flocculants were effective with this slurry, and most of them provided similar cake rates. Moreover, the cake rates obtained with the coarse cloth were not a great deal higher than those with the fine cloth.

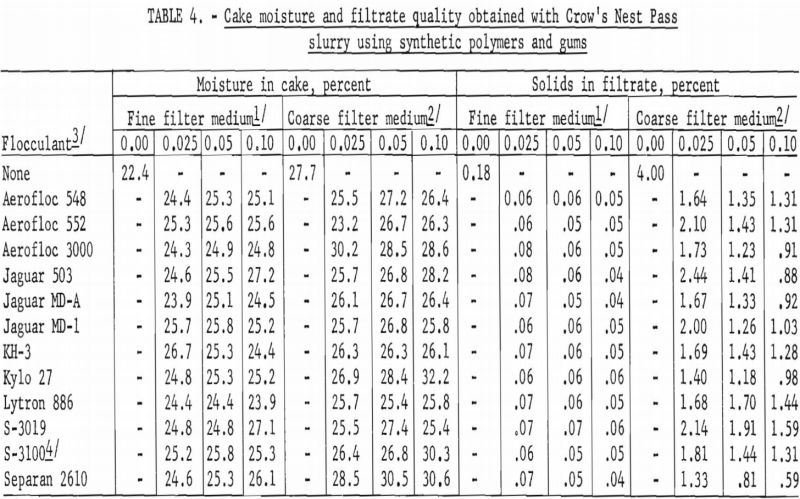

Table 4 shows the moisture content of the filter cakes and the quality of the filtrates obtained with the synthetic polymers and gums. Flocculation increased the moisture content of the cakes obtained with the fine cloth by 2 to 3 percentage points. With the coarse cloth, however, some of the flocculants increased cake moisture, whereas others decreased it.

Filtrate quality was improved by flocculation, but the degree of improvement varied with type of cloth and flocculant. With the fine cloth all of the flocculants reduced the solids in the filtrate to about the same level, 0.04 to 0.08 percent. With the coarse cloth the degree of filtrate improvement was much more variable, some flocculants being distinctly superior to others.

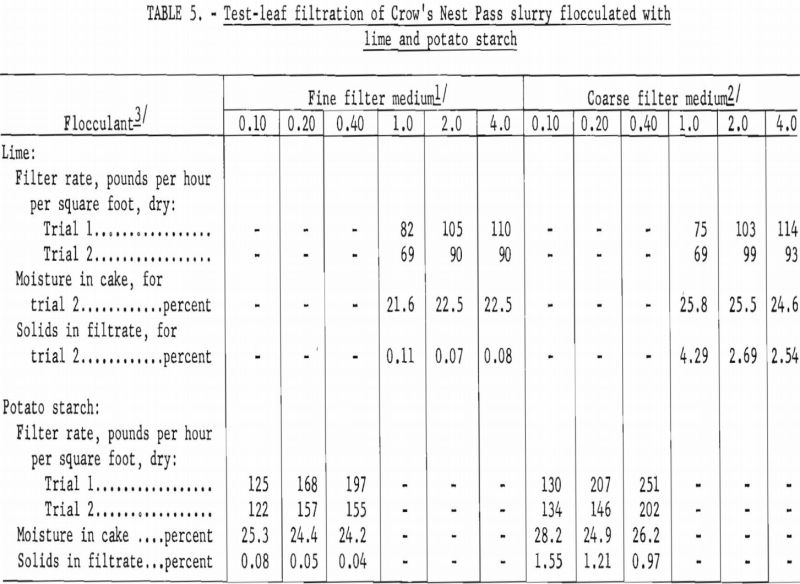

The amount of Crow’s Nest Pass slurry available did not permit testing lime and starch at the low concentrations employed for the other flocculants; they were used at concentrations ranging from 0.10 to 4.0 pounds per ton, as shown in table 5. Lime was not a particularly effective reagent with this slurry. Even when used at a rate of 4 pounds per ton, it provided only a two¬fold increase in cake rate. Starch, on the other hand, when used at 0.4 pound per ton, provided cake rates that were fully as great as those obtained with the newer flocculants, and equaled them in terms of cake moisture and filtrate quality.

Tests With Roslyn-Cascade Slurry

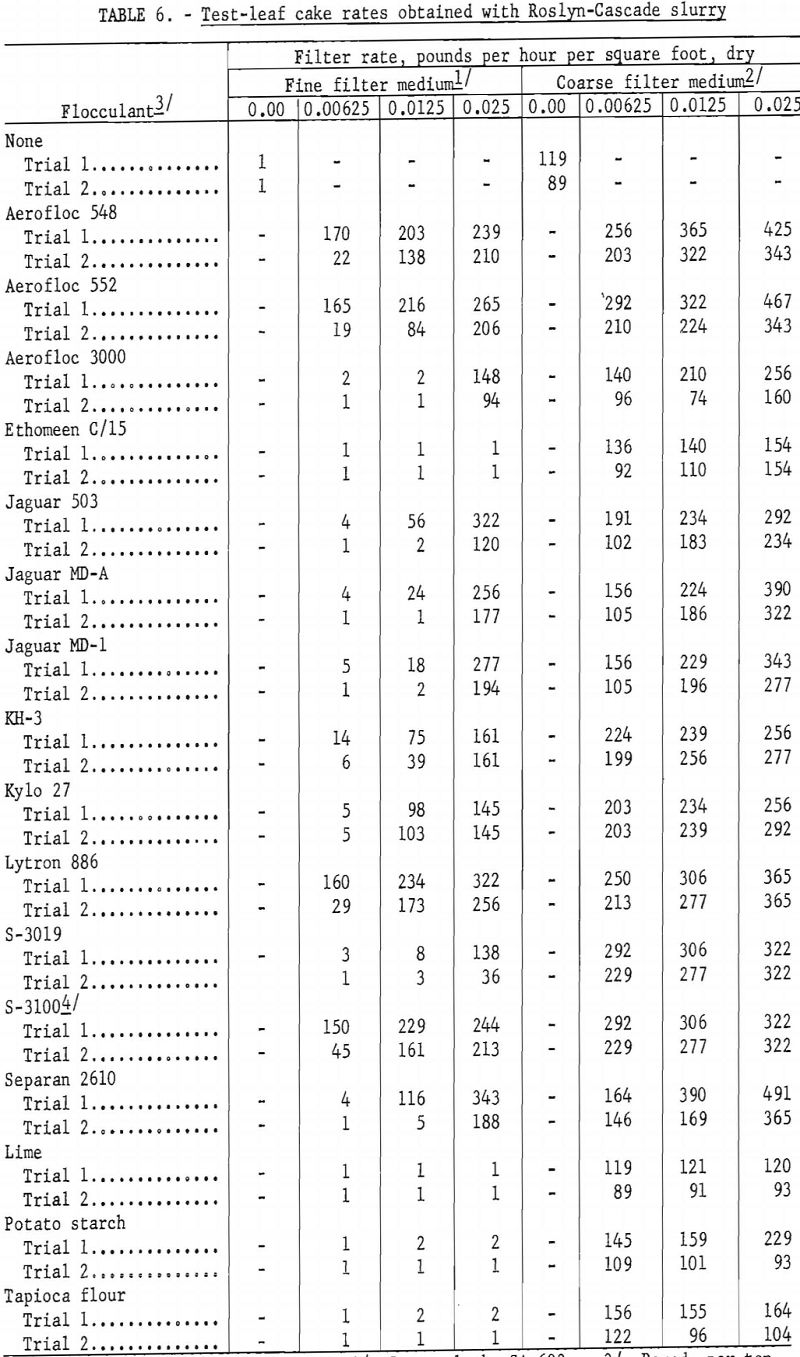

In untreated form the Roslyn-Cascade slurry could not be filtered with the fine cloth, because the clay slimes caused complete blinding almost instantly. Use of the coarse cloth, however, provided first- and second-trial cake rates of 119 and 89 pounds per hour per square foot, respectively. The reduction in cake rate sustained in the second trial indicates that blinding was a factor even with the coarse cloth.

Table 6 shows the cake rates obtained with flocculation. Considering first only the fine cloth, the minimum addition of flocculant was of little benefit, but when the concentration was doubled to 0.0125 pound per ton some of the flocculants provided good filtration. At maximum concentration Ethomeen, lime, starch, and flour still were completely ineffective, but all of the other flocculants provided distinct improvement in cake rate. Lytron was particularly effective, giving a second-trial cake rate of 256 pounds.

Naturally, since the untreated slurry filtered readily with the coarse cloth, flocculation did not provide such dramatic improvement. However, a number of the flocculants gave cake rates in excess of 300 pounds; Lytron again provided the maximum rate.

With most of the flocculants, the cake rate on the second trial was significantly lower than that of the first trial because of the combined influence of floc disintegration and cloth blinding. The reduction in rate was particularly noticeable with the fine cloth and lower flocculant concentrations. It is noteworthy, therefore, that, with a few flocculants, no reduction in cake rate occurred, indicating that blinding was eliminated and that the floes were unusually strong.

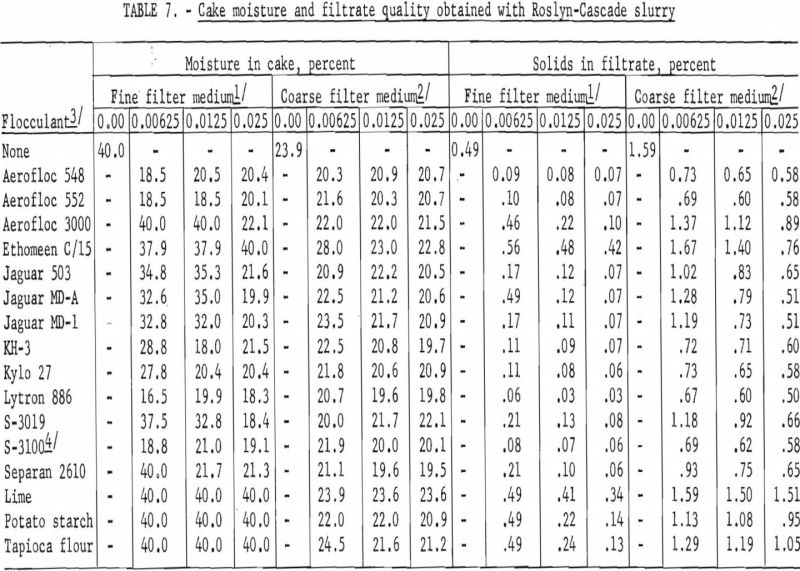

Table 7 shows the cake moisture and filtrate quality obtained with this slurry. The moisture contents of the cakes obtained with both cloths were quite similar, falling within the range of 19 to 22 percent for well-flocculated slurry. The flocculants that provided the highest cake rates also gave cakes of the lowest moisture content. Sometimes moisture content increases with cake rate, because of the greater difficulty of sucking water through the increased thickness of cake, but such was not the case with this slurry. Evidently the thicker cakes were more porous.

Filtrate quality was highly variable but in a general way was related to the completeness of flocculation. Lytron was as superior in this respect as in terms of cake rate and cake moisture, for it reduced the solids content of the filtrate to 0.03 percent with the fine cloth and 0.50 percent with the coarse cloth, both representing minimum values.

With this slurry, lime, potato starch, and tapioca flour were substantially ineffective at the concentrations shown in the tables and showed no real tendency toward increasing in effectiveness with increasing concentration. However, at a concentration of 0.20 pound per ton starch was fully as effective as the lower concentrations of the best flocculants.

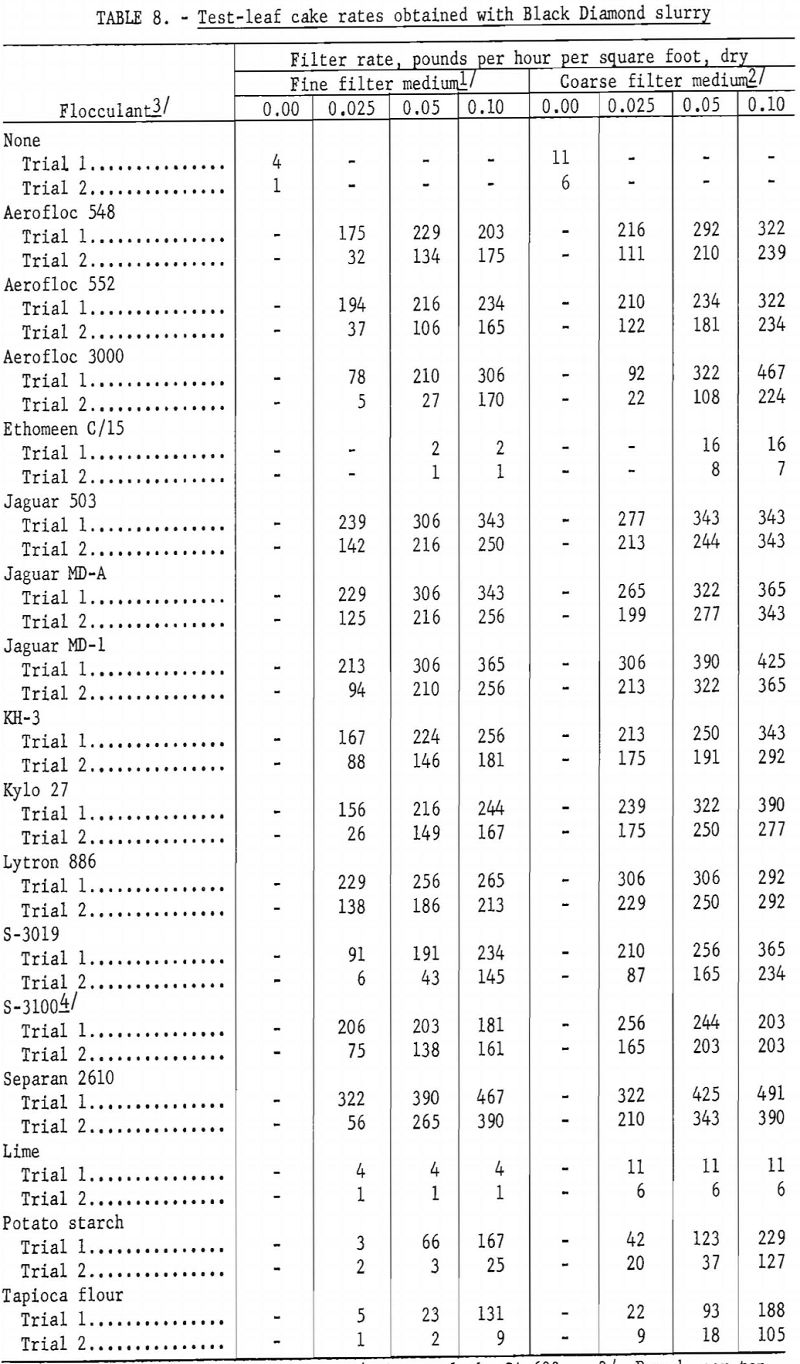

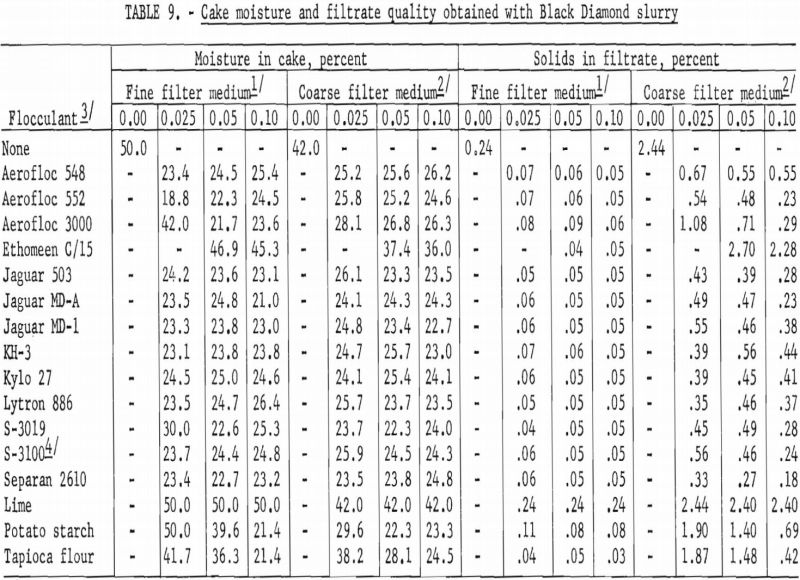

Tests With Black Diamond Slurry

In untreated form this slurry was unfilterable with the fine cloth, and virtually so with the coarse cloth, because of the blinding effect of the clay slimes. As shown in table 8, most of the flocculants produced a marked increase in cake rate, even at the minimum concentration of 0.025 pound per ton. However, at this concentration flocculation was incomplete, and the flocs were rather weak, as demonstrated by the substantial differences between the first- and second-trial cake rates. Doubling the concentration improved the results obtained with most of the flocculants, but further increase to a concentration of 0.10 pound per ton did not create much additional improvement.

At the lower flocculant concentration the coarse cloth gave distinctly higher cake rates than the fine cloth, but at maximum concentration most of the flocculants provided substantially the same rate with either cloth.

Separan was the most effective flocculant, giving a second-trial cake rate of 390 pounds. The three gums were nearly as effective and provided stronger flocs. At the low concentrations shown in the tables starch and flour were inferior. As with the Roslyn-Cascade slurry, when the concentration of starch was increased to 0.20 pound per ton it rivaled the other flocculants in effectiveness.

As shown in table 9, with the better flocculants cake moisture ranged from 21 to 23 percent for the fine cloth and 1 to 2 percentage points higher with the coarse cloth. In some cases the higher moisture content of the cake obtained with the coarse cloth could be attributed to increased cake thickness; but with other flocculants the cake thicknesses on the two cloths were almost identical, yet the coarse-cloth cakes were wetter.

All of the effective flocculants, regardless of concentration, provided filtrates with the fine cloth containing 0.04 to 0.09 percent solids. With the coarse cloth the range in solids concentration was much greater—from 0.18 to 1.08 percent. Separan, which gave the highest cake rate, also gave the cleanest filtrate.

Experiments With Synthetic Slurries

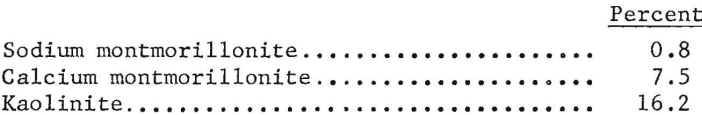

The filterability of a slurry is related to the amount and nature of the extreme fines present. Clay is known to impede filtration, and it was believed that various types of clay might affect filtration in different degrees, because in earlier Bureau work involving the influence of clay on the viscosity of dense medium the mineralogical composition of clay was found to be a controlling factor. Therefore an investigation of the influence of individual types of clay on filtration and flocculation was undertaken.

A synthetic slurry matching the size composition of the Black Diamond slurry shown in table 1 was prepared by grinding a clean bituminous coal from Utah to the required fineness. This slurry gave a cake rate of 391 pounds per square foot per hour with the coarse cloth. Then admixtures of three different clays were made. One clay was a bentonite containing principally sodium montmorillonite, the second was a bentonite in which the predominant clay mineral was calcium montmorillonite, and the third contained principally kaolinite. The first step was to determine how much of each clay was required to reduce the test-leaf filtration rate to an arbitrary level of 50 pounds. The following percentages were required:

Thus it is evident that the type of clay contaminating a slurry has a major bearing on filtration properties.

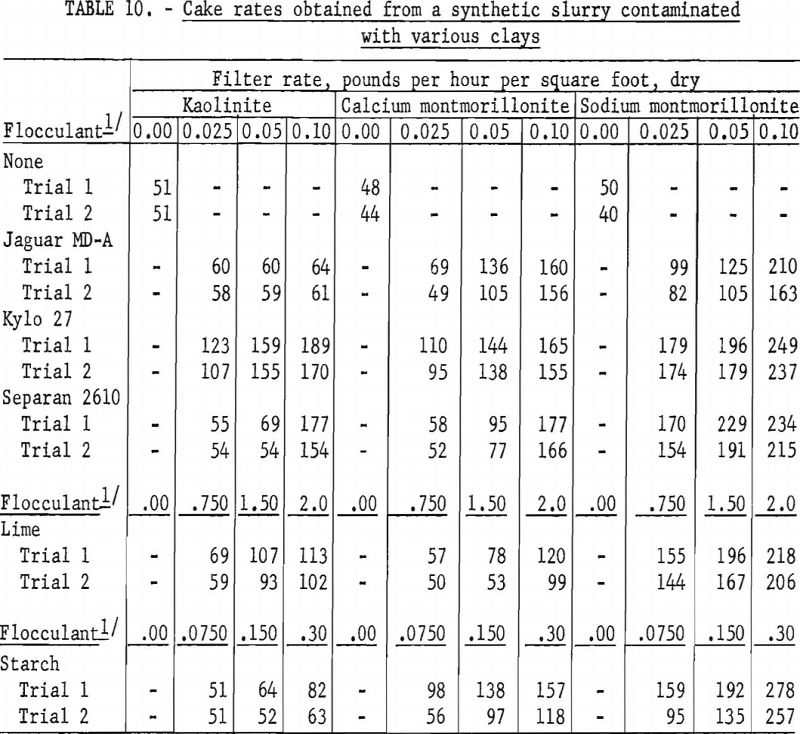

Samples of the synthetic slurry contaminated with the amounts of the individual clays required to reduce cake rate to 50 pounds were flocculated and filtered, using the same test procedures employed for the natural slurries described previously, except that only the coarse filter cloth was used. The results of these tests are shown in table 10.

With the kaolinite-contaminated slurry neither Jaguar nor starch was effective. Kylo was the best flocculant, followed closely by Separan. Lime, which had proved ineffective with the three natural slurries, was better than small amounts of either starch or Jaguar.

With the slurry containing calcium montmorillonite, Jaguar, Kylo, and Separan were approximately equal in effectiveness, and starch at a concentration of 0.3 pound per ton was nearly as effective as the three better flocculants at 0.10 pound.

With the slurry containing the sodium montmorillonite clay all five flocculants were about equally effective when used at their maximum concentration, each of them providing a four to fivefold increase in cake rate.

Filtration With Disk Filter

The test-leaf apparatus is the standard tool for preliminary appraisal of filtration characteristics and the only method that was feasible for testing all the flocculants and slurries used in the present investigation; however, confirming filtration tests were made with two of the natural slurries and several of the flocculants in a laboratory-size disk filter.

Description of Apparatus and Test Procedure

The filter employed, shown in figure 2, is a scale model of a commercial unit. It has two disks 2 feet in diameter that operate in a 12-gallon bottom-feed tank containing an agitator. The filter, vacuum pump, blower, and

driving motors are combined in a compact, portable assembly. Capacity of the unit, which has 5.13 square feet of net filter area, is about 1 ton of cake per hour, with a readily filterable slurry.

The filter was fed from a 50-gallon, conical tank in which an electric mixer was suspended for agitation. The tank discharged through a manually operated valve into a funnel that was provided with calibrated nozzles to regulate the flow. A wet-type reagent feeder was used to add flocculant to the discharge of the funnel at the entrance to a 10-foot length of pipe that carried the slurry to the filter by gravity.

This arrangement for flocculating and feeding the slurry to the filter was the result of experimenting with a number of methods. It was adopted only after extensive testing demonstrated that with it slurry delivered to the filter exhibited the same test-leaf cake rate obtained in the standard test-leaf slurry-preparation procedure. With the other methods tried, either floc degradation was excessive (as in pumping the slurry) or flocculation was incomplete (as when there was no provision for adequate mixing of flocculant and slurry).

In making a test the conical tank was charged with 50 gallons of slurry containing 40 percent of solids that had been soaked 24 hours. The reagent feeder was set for the desired rate of flocculant addition, and the funnel was fitted with the proper nozzle for the flow rate required. As the flocculated slurry started flowing to the filter, the agitator was turned on and disk rotation started; the vacuum was turned on just as the filter tank began to overflow. Once full cake thickness was developed the cake and filtrate were diverted to tared containers for a 5-minute period. After weighing, the cake was sampled for moisture content, and a sample of the filtrate was dried to determine solids content.

A standard cycle time of 3 minutes per revolution was used, giving 27 percent form time and 37 percent drying time. With unflocculated slurry the agitator was operated at 150 r.p.m.; but with the flocculated slurries, which at 40-percent solids were quite stable, agitator speed was reduced to 100 r.p.m. The amount of vacuum ranged from 25 to 17 inches of mercury, depending on cloth and cake conditions.

Disk-Filter Test Results

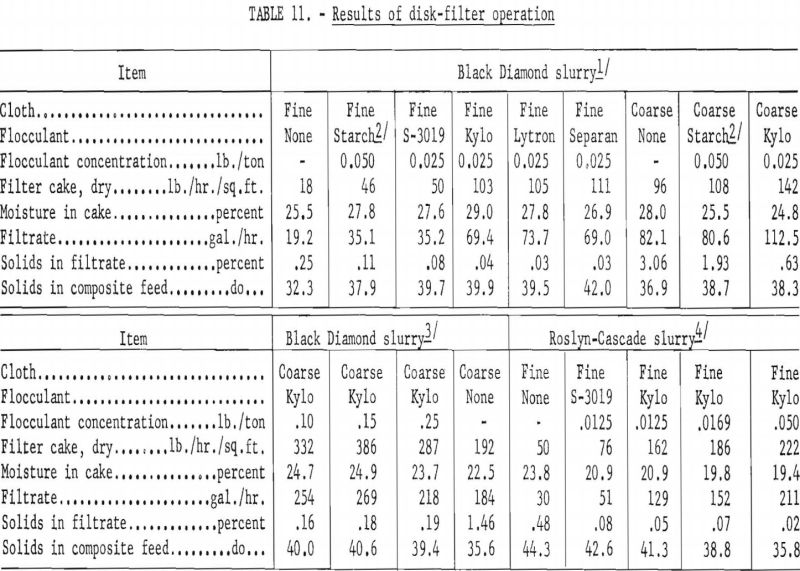

The principal difference between the results obtained with the disk filter and those from the test-leaf apparatus was in the behavior of the unflocculated slurries. As shown in table 11, the unflocculated Black Diamond slurry gave disk-filter cake rates of 18 and 96 pounds per hour per square foot with the fine and coarse cloths, respectively, whereas the test leaf showed this slurry to be essentially unfilterable with either cloth. Apparently the agitation in the tank of the disk filter was sufficient to prevent settling; thus the initial layer on the filter cloth contained enough granular coal, along with the clay slimes, to create a permeable cake; in contrast, the test leaf picked up only slimes, which sealed the cloth.

With the flocculated Black Diamond slurry the two filters compared more favorably. In every instance the cake rate for the disk filter was intermediate between that of the first and second test-leaf trials. This relationship suggests that the amount of floc breakdown observed in the second trial runs of the test leaf was somewhat more severe than that experienced in feeding the disk filter. For a particular flocculant, the filtrate obtained with the fine cloth on the disk filter was slightly cleaner than that provided by the fine cloth on the test leaf, whereas with the coarse cloth the filtrates from the disk filter were somewhat higher in solids content than those from the test leaf. Cake moistures with the disk filter were consistently higher than those with the test leaf, the difference ranging from a few tenths of a percent to a maximum of 4.5 percent.

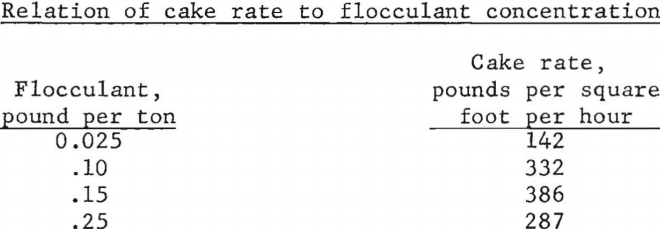

The series of disk filter tests in which the Black Diamond slurry was flocculated with various amounts of Kylo illustrates the well-known fact that an excessive amount of flocculant can cause a reduction in cake rate. As shown in the following tabulation, cake rate increased steadily with greater concentrations of flocculant, reaching a maximum of 386 pounds per square foot per hour at 0.15 pound of Kylo per ton, but then dropped nearly 100 pounds when the flocculant concentration was increased further to 0.25 pound per ton:

With the Roslyn-Cascade slurry the cake moistures and filtrate qualities shown in table 11 were virtually the same as those obtained with the test leaf, but the cake rates with the disk filter were consistently higher. In the case of either the unflocculated slurry or the poorly flocculated condition obtained with S-3019 the superiority of the disk filter can be attributed to better agitation in the feed tank, as was the case with the unflocculated Black Diamond slurry. However, the high disk-filter cake rate obtained with Kylo is unexplained.

Despite the few inconsistencies mentioned, the work with the disk filter confirmed the principal conclusions reached with the test leaf; that is, the filtration of both slurries was improved by flocculation, and the individual flocculants varied in effectiveness.