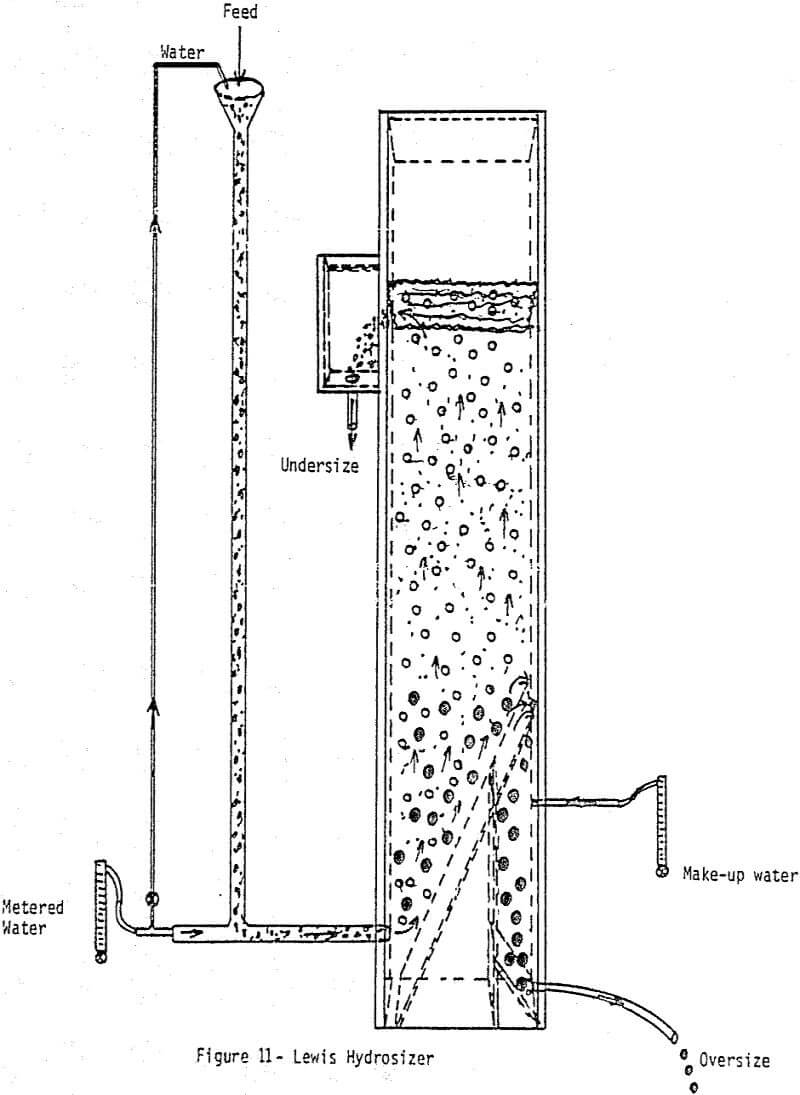

The unit consists of an elongated box set on end, with the height being approximately 3 to 4 times greater than the base width. A baffle plate is secured inside the box at the bottom and sides and at an angle so as to leave a small opening at the top. The baffle rises to a height of approximately one third the height of the box. A pipe to remove the coarse- size material is located at the bottom of the box behind the baffle.

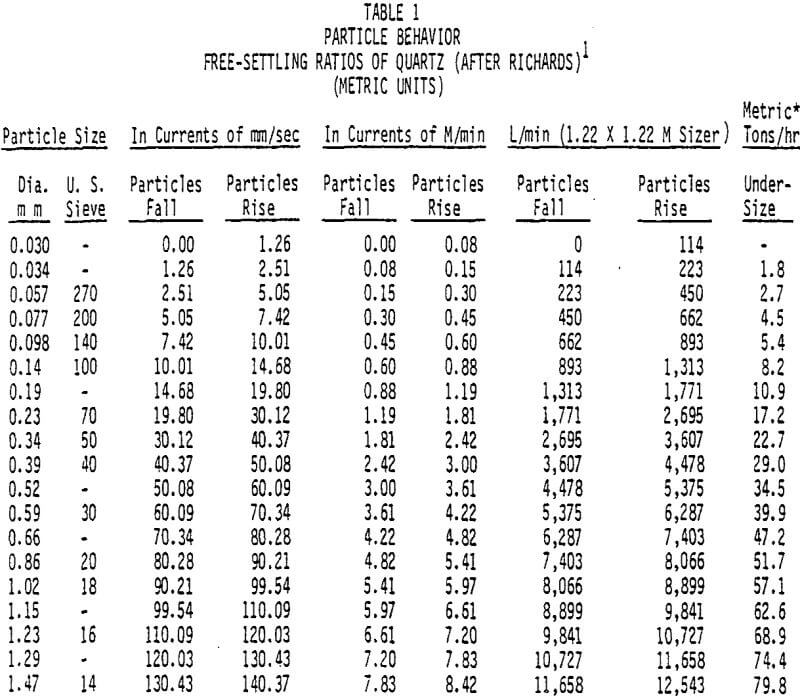

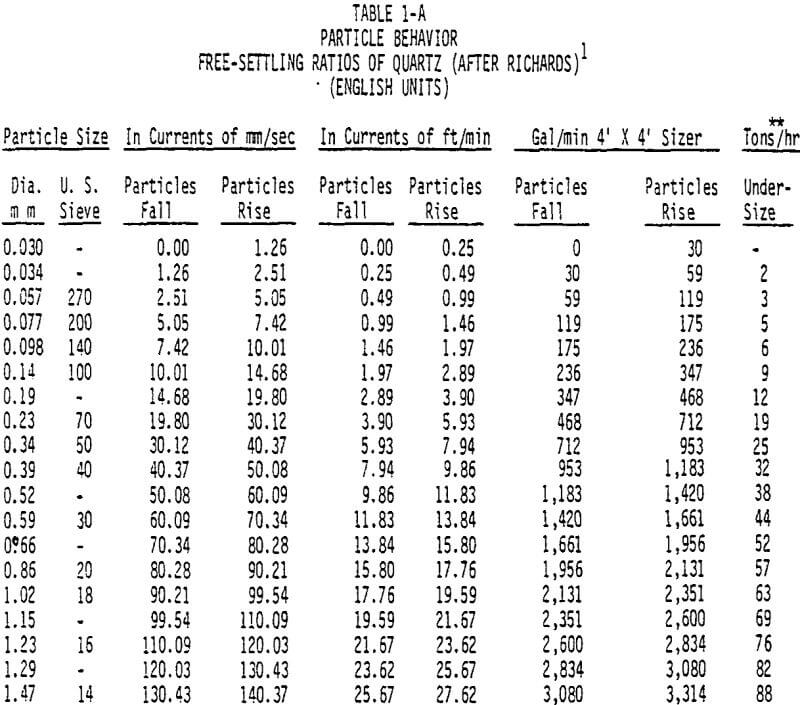

A pulp consisting of water and assorted sizes of mineral grains is pumped or gravity fed into the bottom side of the sizer. The material discharges against a deflection plate which changes the direction of flow to an upward thrust. The rising current carries the undersize material to the top of the sizer where it overflows by way of a launder. The oversize material cannot rise at the set velocity, and keeps settling out until forced by mass action over the top edge of the deflection plate into a hopper.

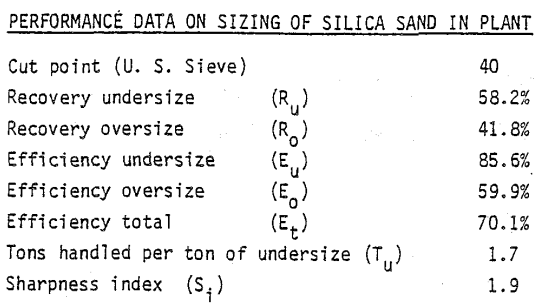

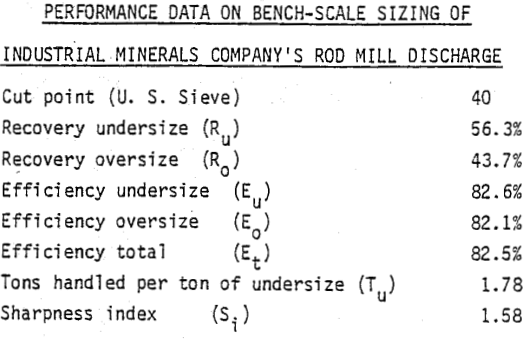

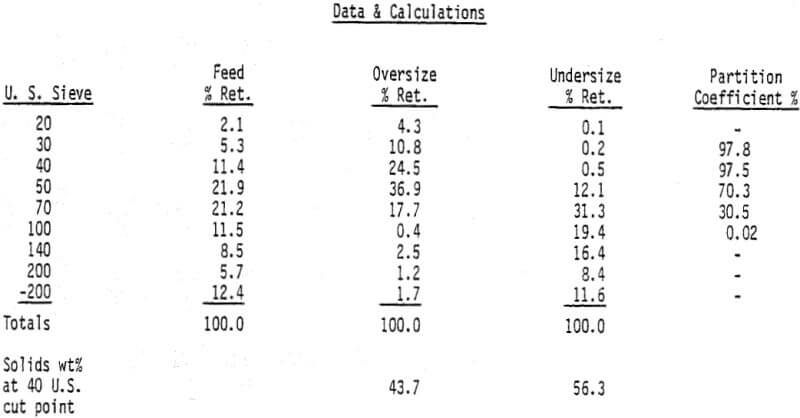

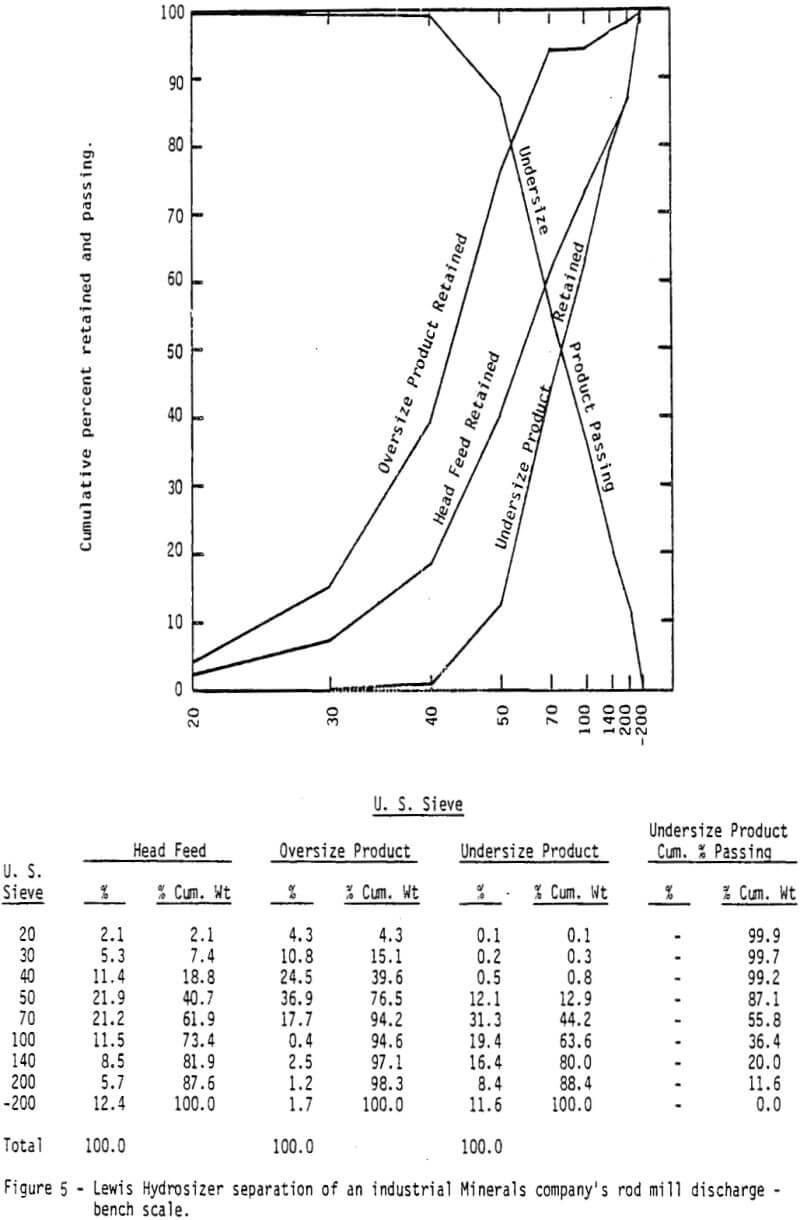

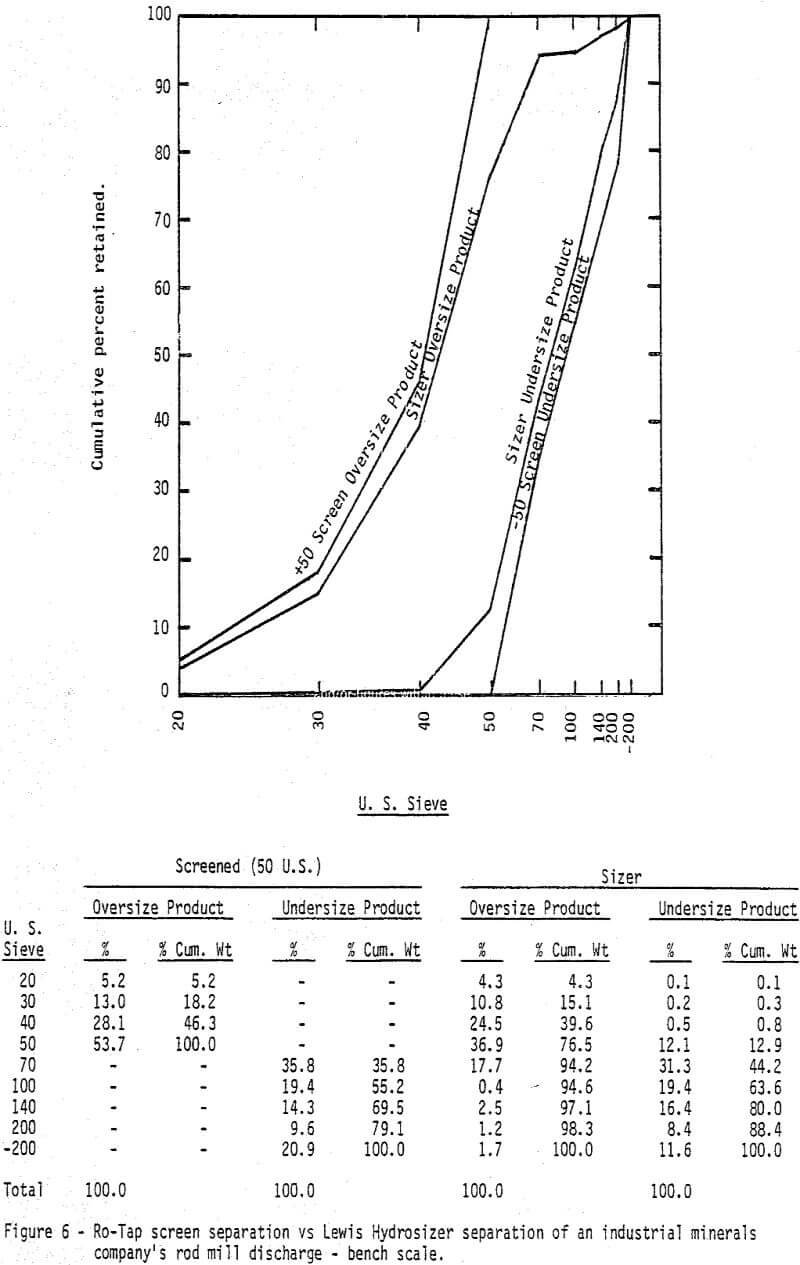

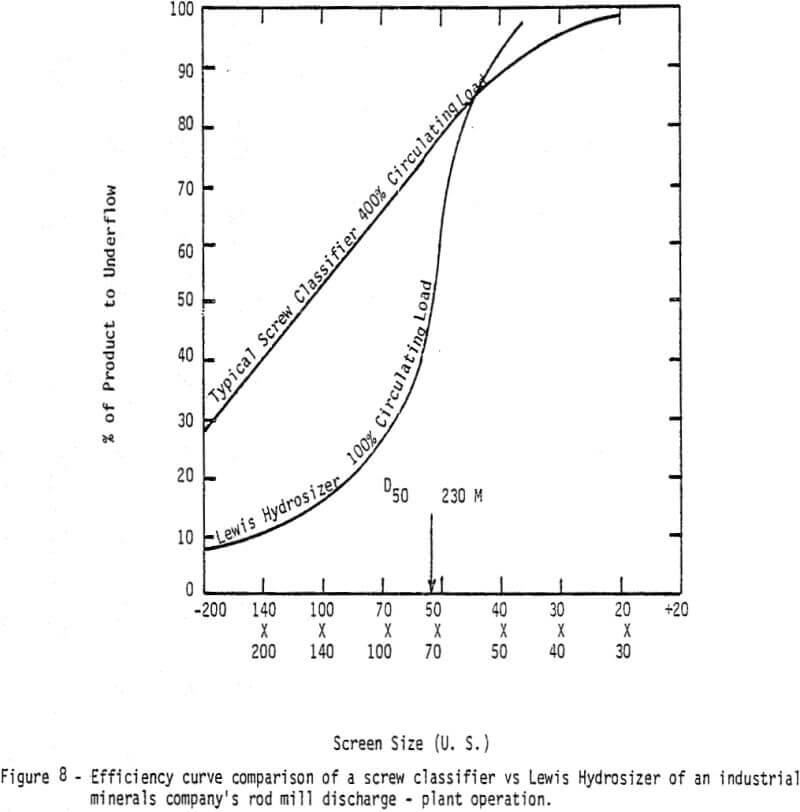

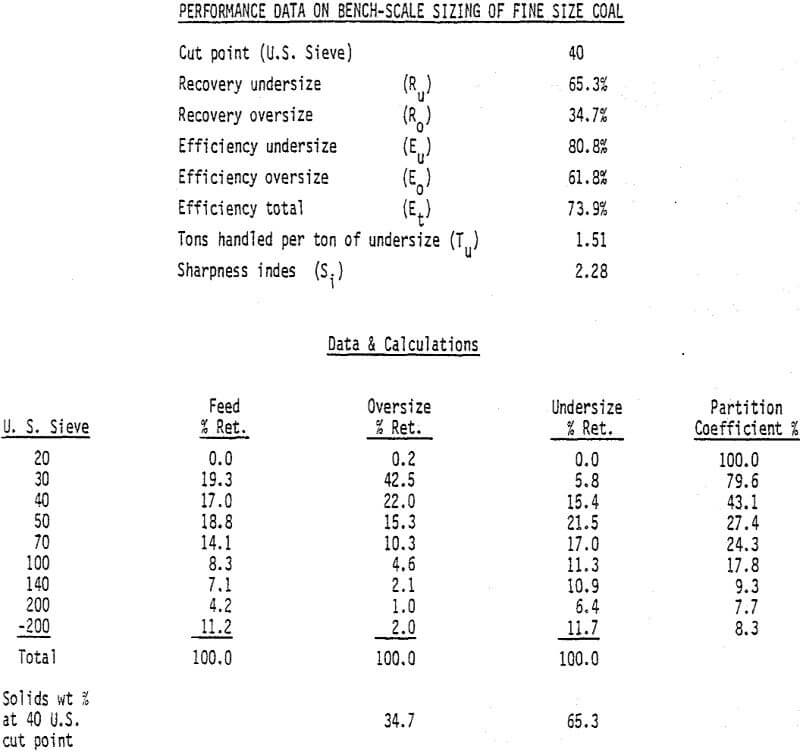

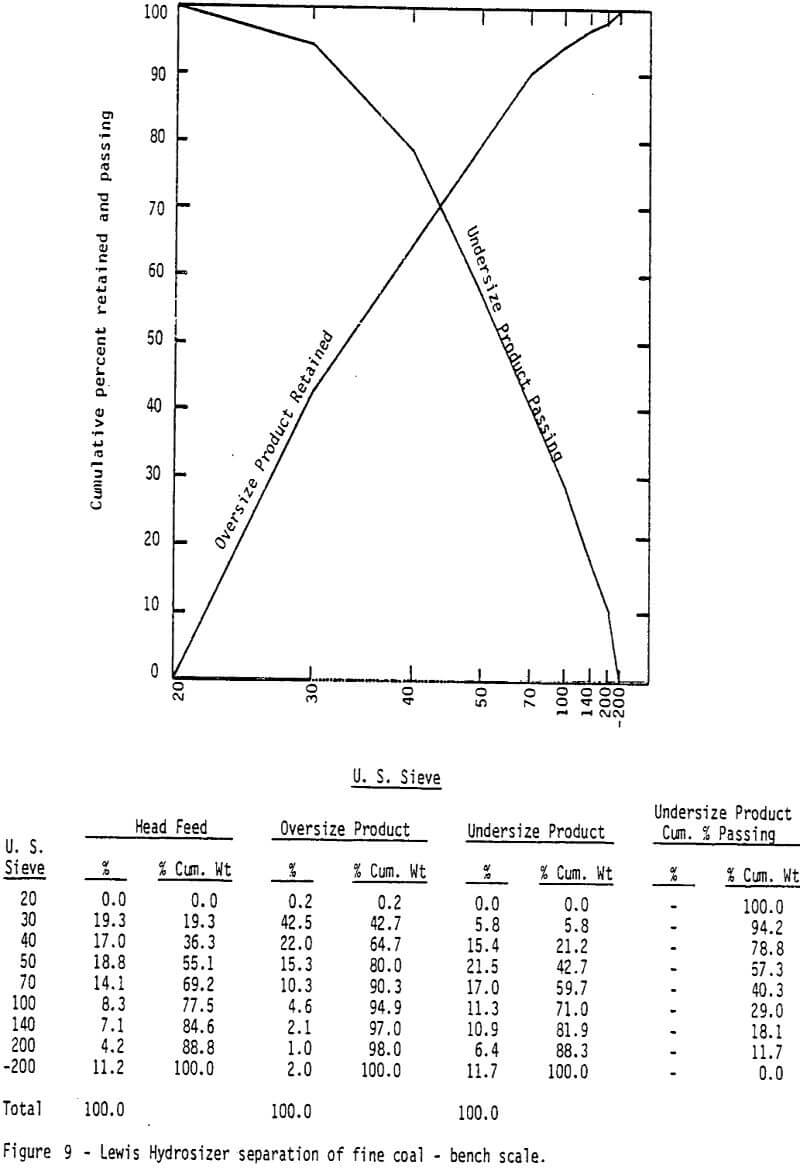

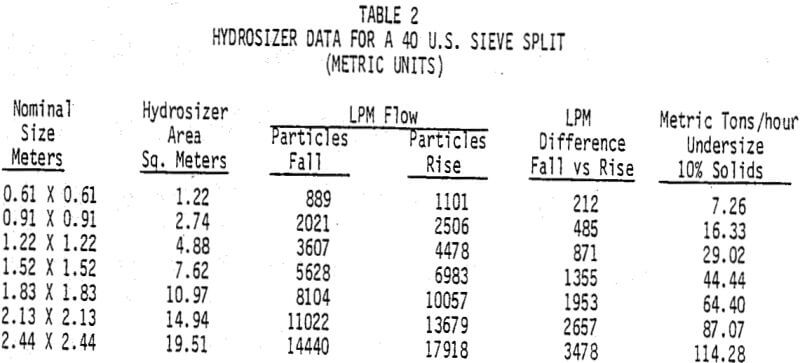

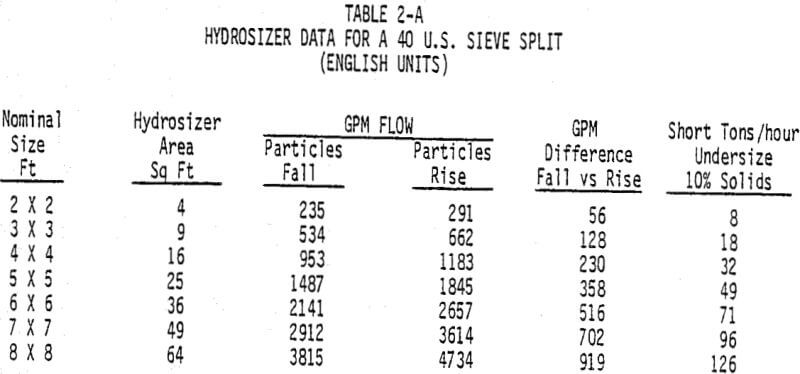

Samples of feed to sand plants and industrial minerals plants, olivine plant tailings, coal, and others were tested in the laboratory separator. Most separations were made at 40, 50, 70, and 140 U.S. sieve. Products from a sand plant and industrial minerals plant were also evaluated. A hydrosizer has been used to size tailings during a mica flotation pilot plant, and in closed circuit grinding.

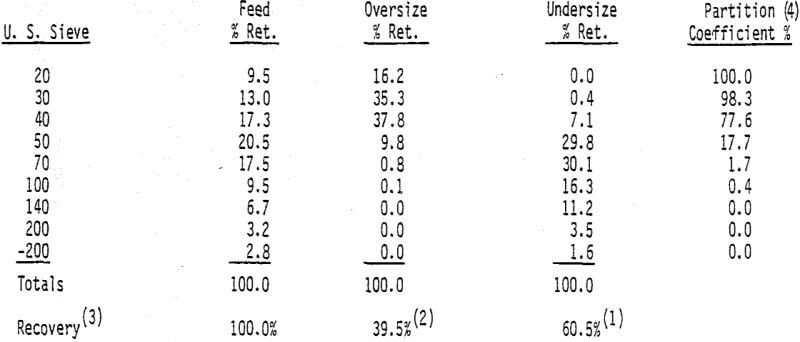

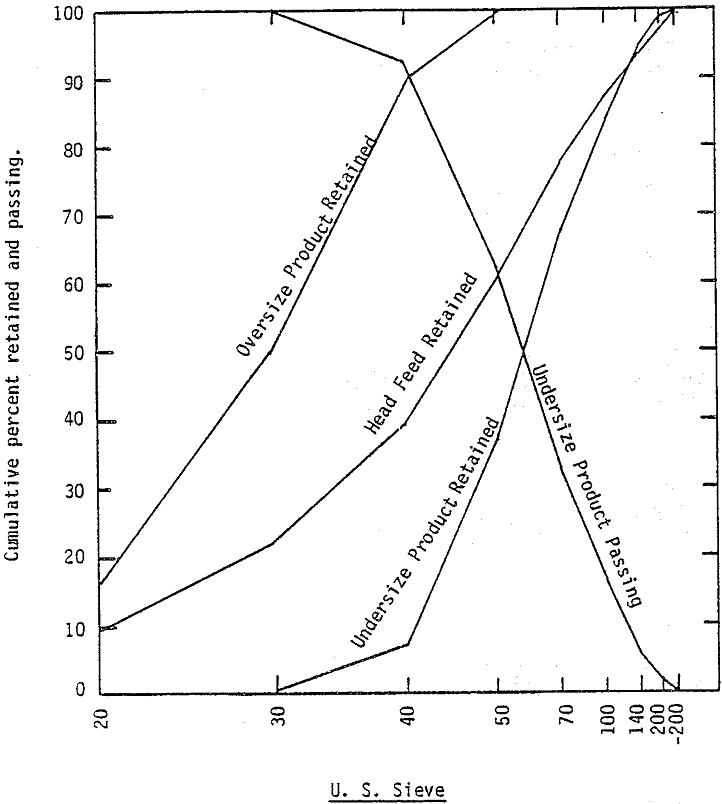

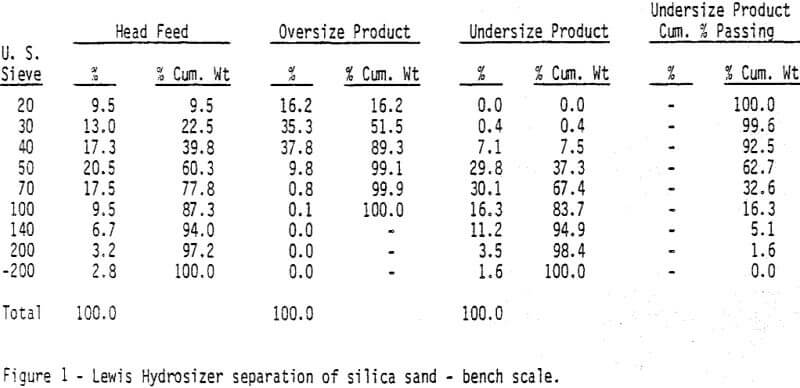

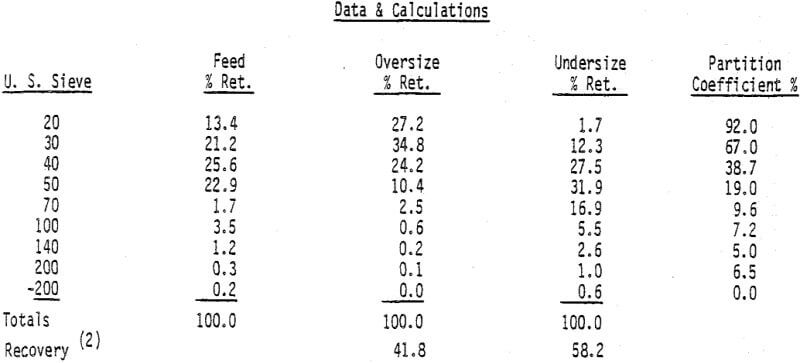

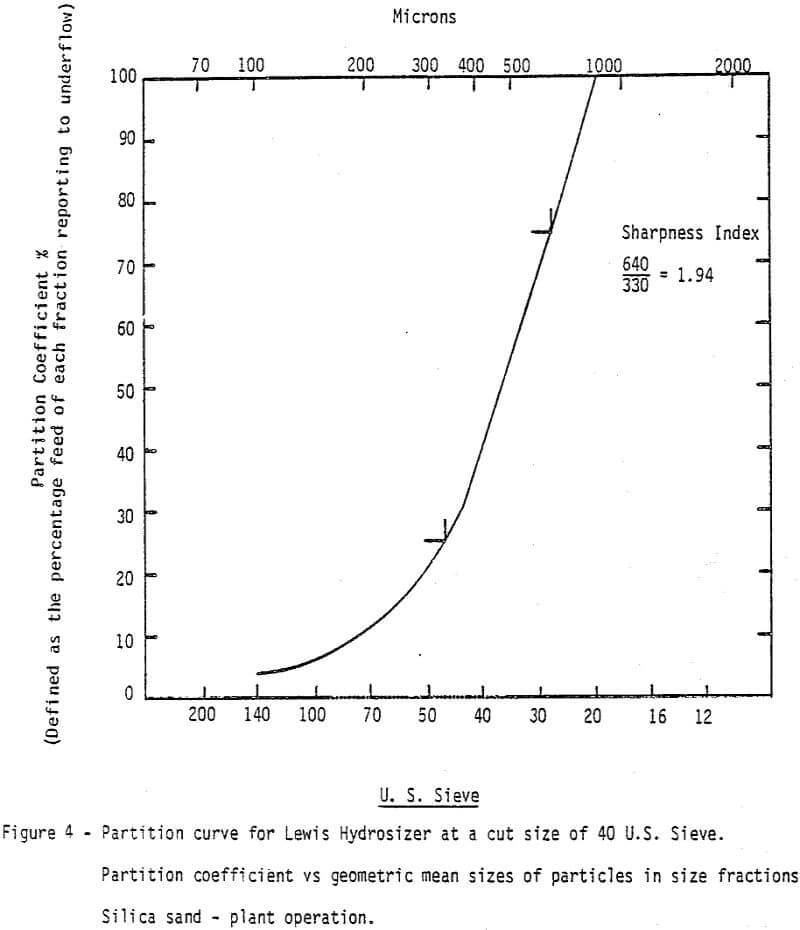

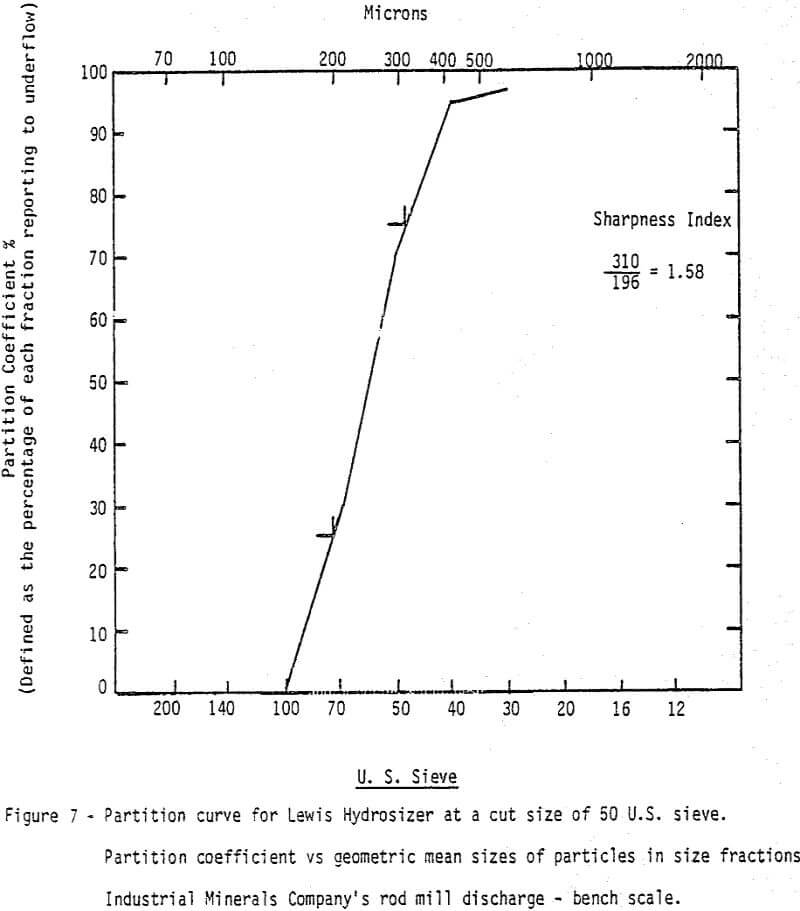

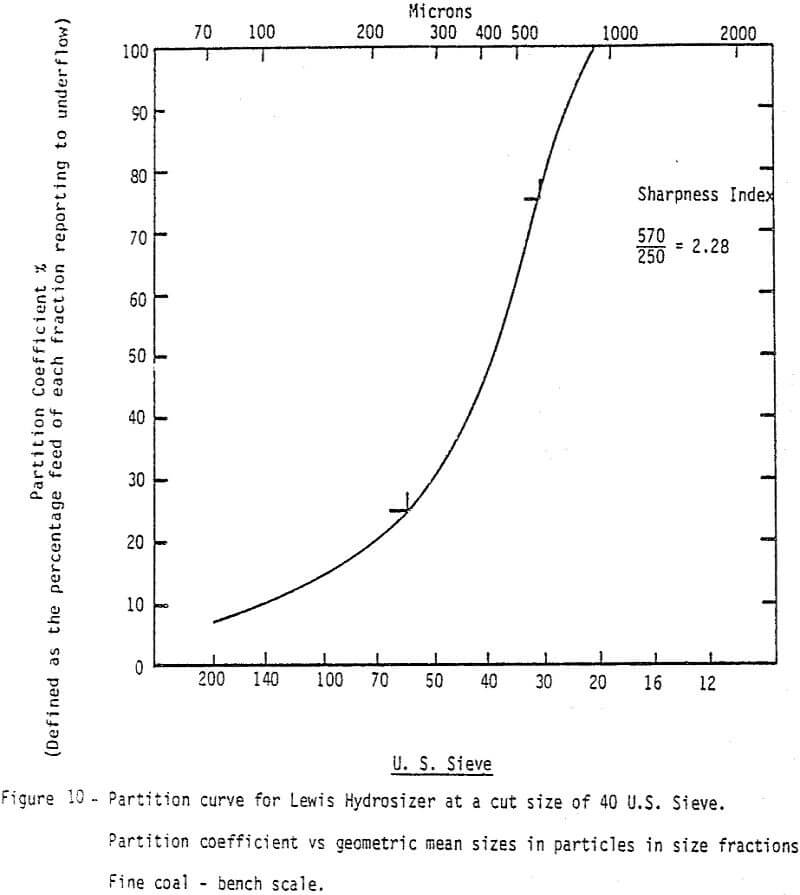

Sieve analyses of feed, oversize and undersize are used to evaluate performance by standard formulas. Also, by plotting the cumulative percent oversize retained and the cumulative percent undersize passing, the point at which the curves cross will give the approximate total efficiency at the sieve size shown. An alternative method for presenting screen and classifier performance is partition curves. The partition curve for a separation is drawn by plotting the partition coefficient, defined as the percentage feed of each fraction reporting to the oversize product, against the geometric mean size on a logarithmic scale.