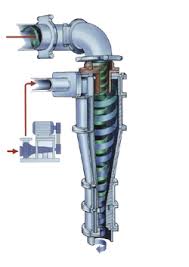

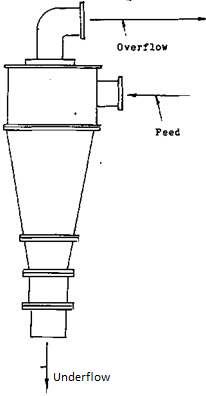

The hydrocyclone operation consist of having the ore slurry pumped into its feed inlet, the ore is then separated by size with the fine material coming out of what is referred to as the “OVERFLOW” via a Vortex Finder. The mineral that still requires grinding is named the “UNDERFLOW” via the Apex Finder.

These two terms, the “overflow” and “underflow” will become very familiar to you. They are used where ever the slurry is “being separated by grind size, density, or mineral content. In this case it is particle size. The cyclone underflow is directed to the ball mill- for further grinding. Once the ore has passed through this mill it will be added back into the material that is being pumped to the cyclone for reclassification.

The hydrocyclone product is the overflow, which of course is finely ground rock. It is this overflow which must be controlled. The grinding circuit must grind the ore fine enough to have the waste rock and the mineral, which is bound to it, liberated from each other. Once the ore has reached the size that metallurgical testing has determined the mineral is liberated at, the cyclone will separate it. This size will be reflected in the density of the overflow.

The higher the density the courser the grind. It will have been determined, metallurgically, what the best density range is for the particular ore that is being processed. This means, that the main control over the grind that is being sent to the next stage of concentration, is in the performance of the cyclone. As DENSITY and VOLUME are two of the main variables that effect cyclone performance, the operator will add or subtract water to the feed of the cyclone to control the size of the grind in the over flow.

When you add water to the feed of the cyclone, the result is the overflow becomes lighter and the underflow becomes heavier. The heavier UNDERFLOW DENSITY will give the ball mill more work to do. This is reflected in a heavier density being fed back into the hydrocyclone feed pump box. Which again changes the hydrocyclone operation performance.