Table of Contents

The profitable operation of a coal preparation plant under today’s stringent product standards and ever-rising labor, material, energy, and equipment costs requires that the preparation engineer continually strive for maximum recovery of salable coal. Good performance data are a prerequisite to the design of a new plant or to the expansion of existing facilities, and they serve as a yardstick with which the engineer may measure the performance of his plant. With these data and a washability analysis of the raw coal, the preparation engineer can make a rational choice of washing equipment.

This report is the fifth in a series of reports on the performance characteristics of the principal coal washing devices used in the United States.

Hydrocyclone Coal Washers and Operation

Hydrocyclone Coal Washers

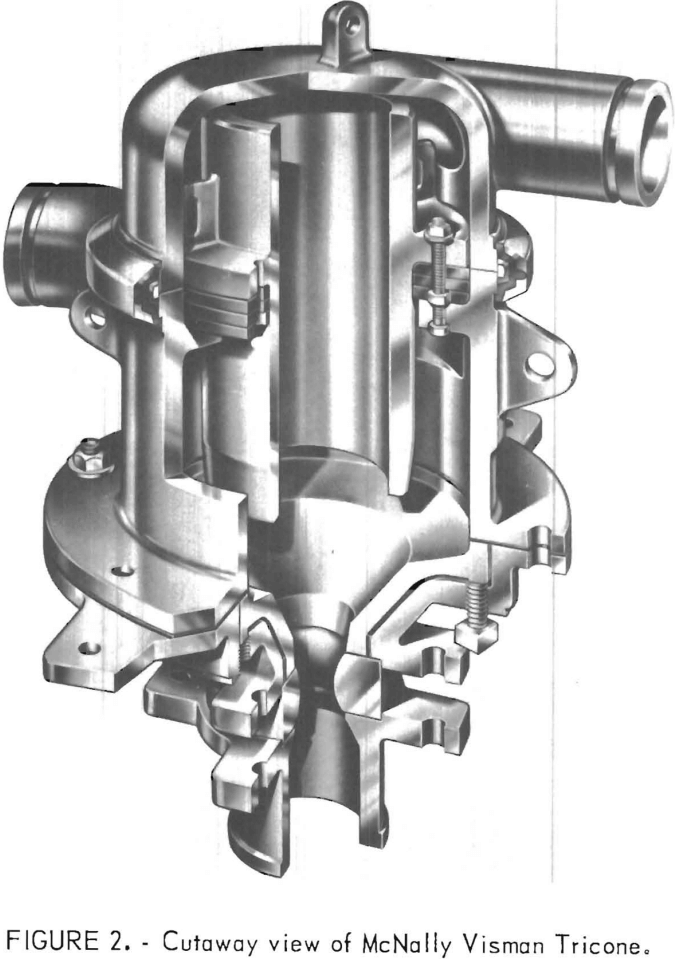

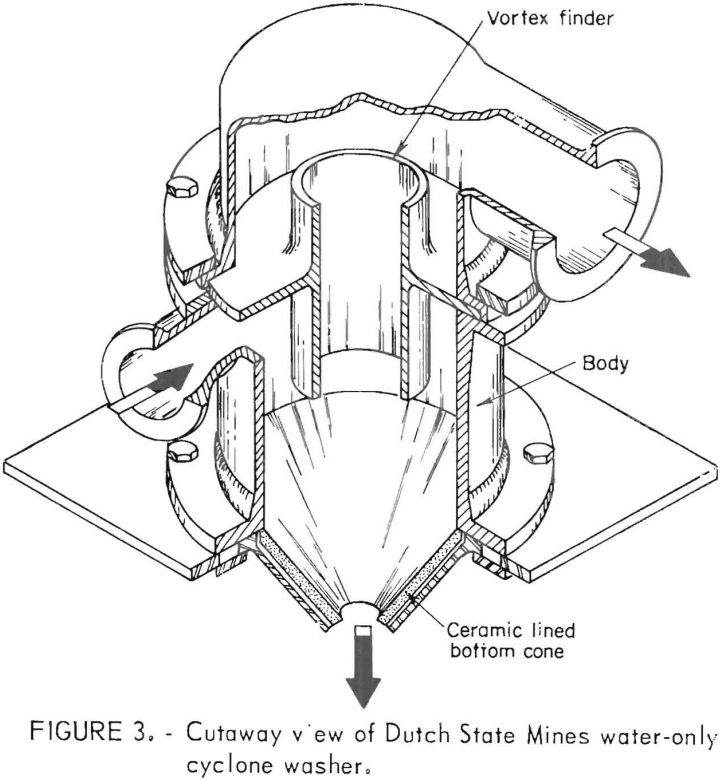

The hydrocyclone, like the dense-medium cyclone, was developed by the Dutch State Mines (DSM). Essentially, it is a cylindro-conical unit with an included apex angle of up to 120°, much greater than the included apex angle of the dense-medium cyclone. The hydrocyclone also has a longer vortex finder than does the dense-medium cyclone.

The coal and water slurry is introduced tangentially and under pressure into a cylindrical section of the cyclone where centrifugal force acts on the particles in proportion to their mass. As the slurry moves downward into the conical section of the cyclone, the centrifugal force acting on the particles increases with decreasing radii. In such a regime, the heavy-density particles of a given size move outward toward the descending vortex much more rapidly than their lighter density counterparts. Consequently, as these lighter density particles approach the apex of the cone, they are drawn into the upward flow vortex adjacent to the central air core and thus report to clean coal. The heavier particles, along the cyclone wall, report to the apex refuse orifice of the cone. Admittedly, this is an over-simplified description of the separation effected in a hydrocyclone which is, in fact, a very complex interaction of many physical phenomena including centrifugal acceleration, centripetal drag of the fluid, and mutual impact of particles.

Hydrocyclones have gained acceptance in the United States principally because of (1) the large tonnage that they can process in a given unit of space in a new or existing facility and the low capital investment required, (2) their ability to make a good “rougher” cut to remove fine-size pyrite before froth flotation, and (3) their ability to produce a good overflow product even though the underflow may be quite poor. In such a circuit, the load on the secondary washer is greatly reduced.

Some of the drawbacks of hydro cyclones are the large quantities of water required for proper operation and the fact they do not provide acceptable final products but require the retreatment of one or both of the products.

Operation

Commercial water-only cyclones of four types are used currently in the United States: Dutch State Mines water-only cyclone washer (sold by Roberts & Schaefer as exclusive U.S. Licensee for coal), Heyl & Patterson hydrocyclone, Krebs hydrocyclone, and McNally Visman Tricone.

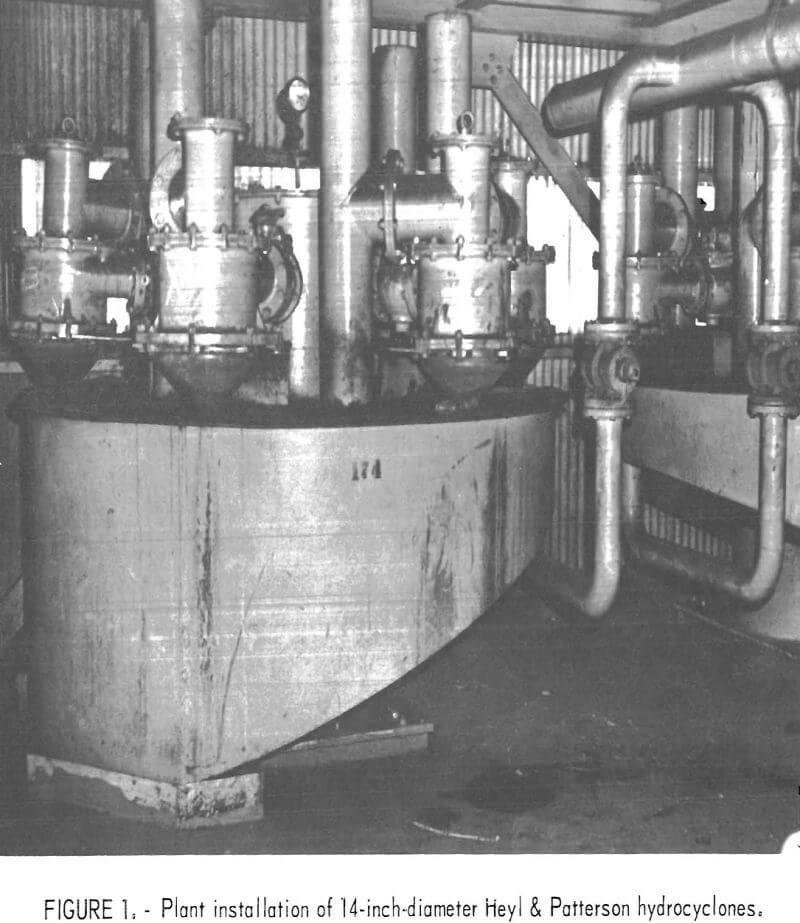

Figure 1 shows a typical plant installation of 14-inch- diameter Heyl & Patterson hydrocyclones.

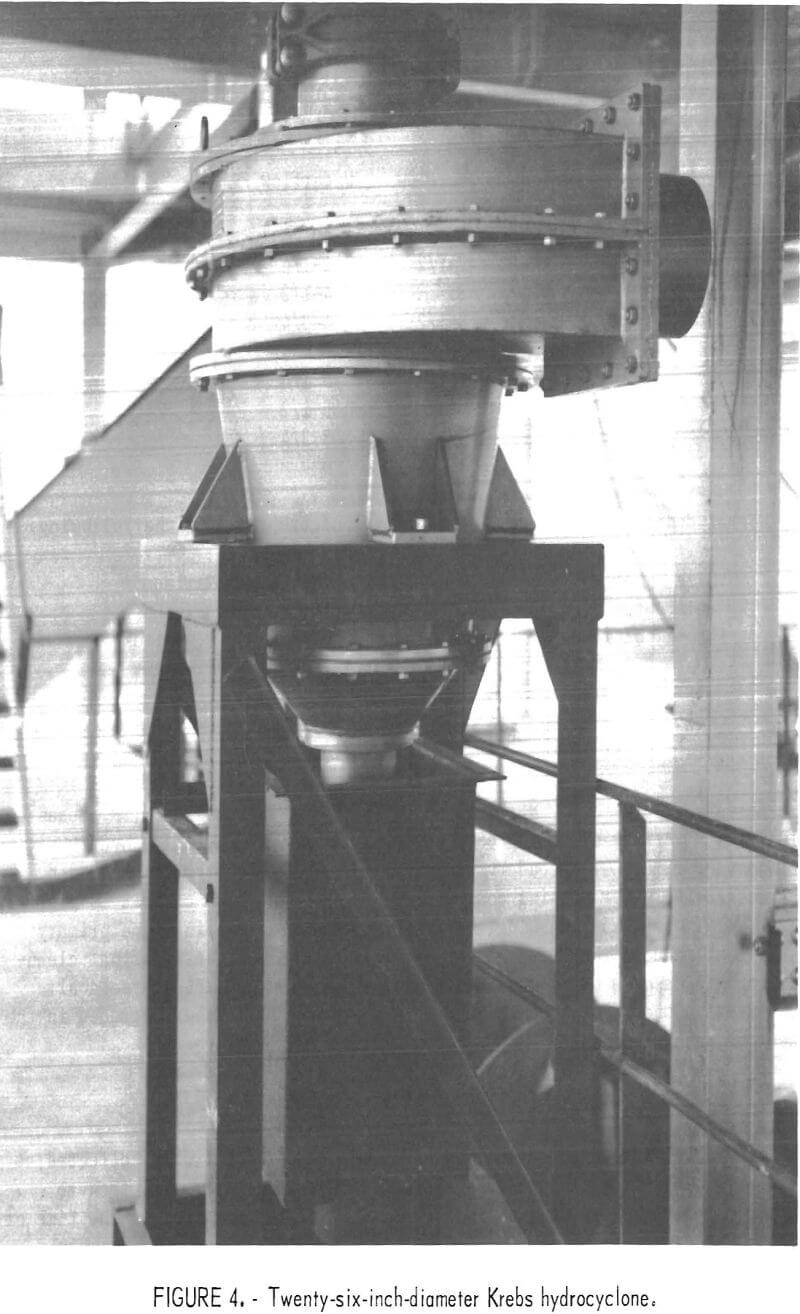

Figures 2 and 3 are cutaway views of the McNally Visman Tricone and the Dutch State Mines water-only cyclone washer, respectively. Figure 4 shows a 26-inch-diameter Krebs hydrocyclone.

Some of the more important factors affecting the operation of a hydrocyclone are feed rate, size consist of feed, percent solids in feed slurry, feed pressure, feed and product orifice sizes, length of vortex finder, cyclone diameter, and included angle.

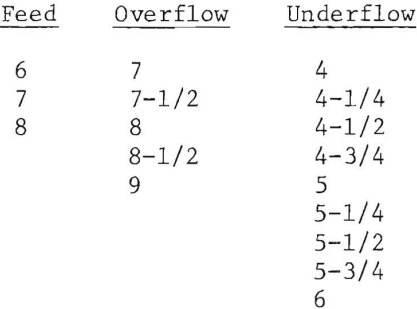

The feed and product orifices vary considerably to suit the coal types and separating characteristics desired. For example, one manufacturer’s 24-inch-diameter hydrocyclone is available with the following orifice diameters, in inches:

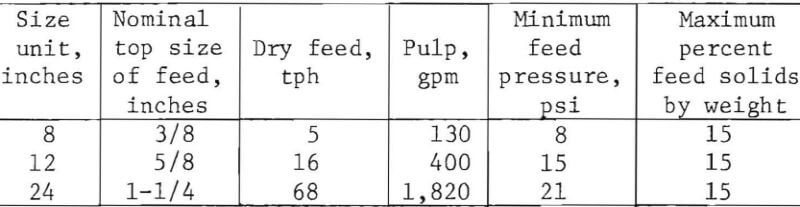

Normal design data for another hydrocyclone are shown in the following:

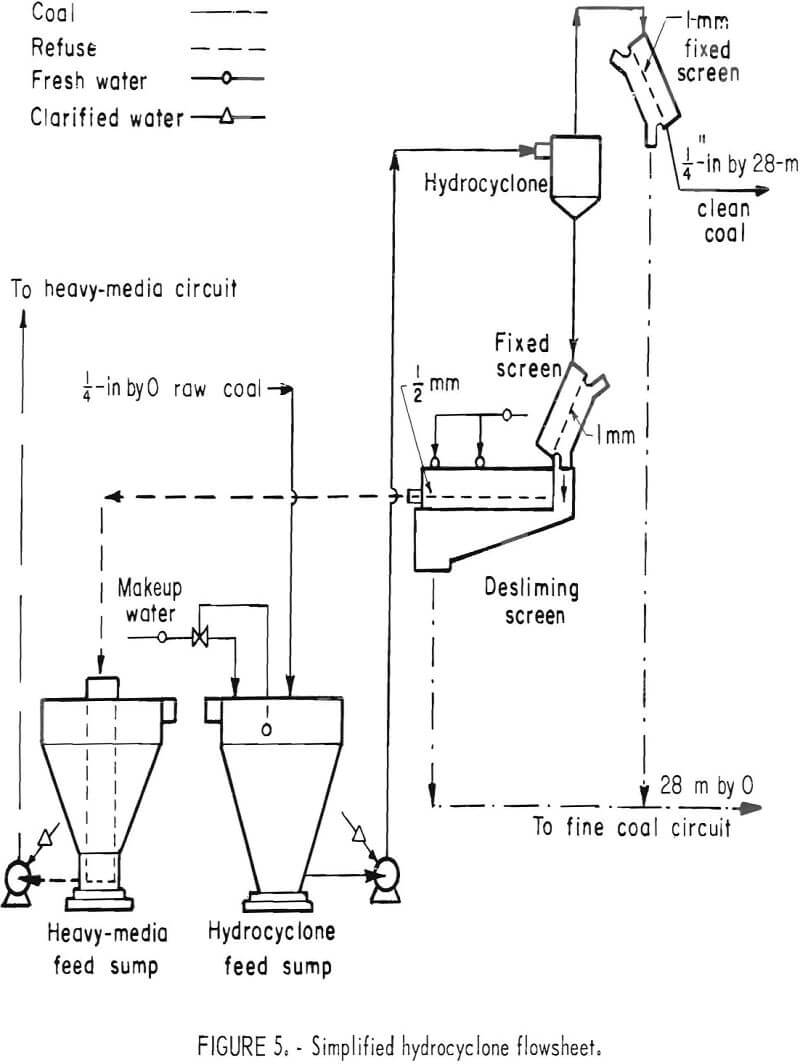

Recent articles by J. W. Collins and by W. E. Foreman and J. R. Lucas illustrate a variety of coal processing flow schemes that utilize hydrocyclones as primary or secondary washers. All of these circuits have been used successfully for washing coal. Consequently, only one circuit is presented herein (fig. 5), showing the hydrocyclone as a scalping-type primary washer that reduces the required capacity for the more expensive final cleaning, in this case, a dense-medium coal washing device for the coarse coal. The fine-size underflow from the hydrocyclone would be further upgraded in the fine-coal washing circuit.

Sampling and Test Procedure

Samples of five hydrocyclone washer feeds and products were collected at four commercial plants. Top sizes of the samples ranged from ¼ inch to 8 mesh. Although the number of hydrocyclone units in operation at the time of sampling was limited, only well-operated plants were sampled.

The gross samples of each product weighed at least 180 pounds and consisted of 60 incremental samples of 3 pounds or more. The samples were collected over a 4- to 6-hour period of normal plant operation, placed in plastic-lined 55-gallon steel drums, and shipped to the laboratory for processing.

In the laboratory, the samples were air-dried, weighed, and then sized at ¼ inch (or 4 mesh), 8, 14, 28, 48, 100, and 200 Tyler mesh, unless noted otherwise. After sizing, the clean coal and refuse products were float-sink tested in organic liquids of various specific gravities ranging from 1.30 to 1.90.

The size fractions of the feed product, the incremental float-sink fractions of the clean coal and refuse products, plus the minus 200-mesh size fractions of the feed, clean coal, and refuse products were sent to the analytical laboratory for chemical analyses.

Hydrocyclone Feeds

The washability analyses of the five samples collected are presented in the appendix in tables A-1 through A-5.

The feed to plant A was extremely fine, 60 percent was minus 200 mesh. Washing such a fine size feed is extremely difficult The other coals presented no special preparation problems.

Plant Operating Conditions

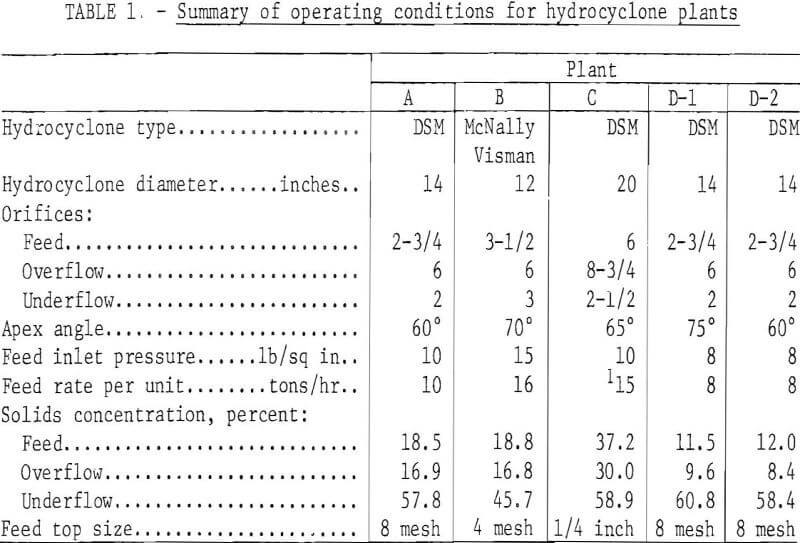

The operating conditions for the five units sampled are summarized in table 1. The feed solids to the plant C hydrocyclone were much too high, otherwise the operating conditions were reasonably consistent with recommended practice.

Performance Criteria

The performance criteria used in this report are those in common usage; hence, only summary definitions are given. More complete definitions may be found in a publication by Yancey and Geer. All performance criteria values are generally considered to be constant only for a given size consist of coal, feed rate, and quality of operation.

Dependent Criteria

Performance criteria that depend both on the washing characteristics of the coal being treated and on the sharpness of the separation achieved by the washer are usually called dependent criteria, and include recovery efficiency, misplaced material, and ash error.

Recovery efficiency is defined as the ratio, expressed in percentage, of the yield of washed coal to the yield of float coal of the same ash content shown to be present in the feed by the specific gravity analysis.

Total misplaced material is that percentage of the feed that reported to the wrong product. For sharp separations, the misplaced material has a specific gravity close to the specific gravity of separation and thus correlates with the amount of near gravity material.

Near-gravity material is the percentage of material in the feed within ±0.10 specific gravity units from the specific gravity of the separation.

Ash error is closely related to recovery efficiency and is of practical importance in that it indicates the difference between the ash content of the clean coal product and the theoretical ash from the washability data at the same yield.

Independent Criteria

Performance criteria that are characteristic of the washing unit and are substantially unaffected by the specific gravity composition of the raw coal are probable error, error area, and imperfection factor. They are commonly referred to as the sharpness-of-separation criteria.

Probable error is measured directly from the distribution curve. It is the slope of the distribution curve, and it equals one-half the specific gravity difference between the 25- and 75-percent ordinate values on the curve.

Error area, the area between the actual distribution curve and the theoretically perfect distribution curve, is a measure of the sharpness of the separation between clean coal and refuse. For a theoretically perfect separation, the error area is zero.

The sharpness-of-separation for most cleaning devices deteriorates with increasing specific gravity of separation. Recognizing this, Cerchar (Centre d’Etudes et Recherches des Charbonnages de France) developed the imperfection factor, which, for jigs, tables, and other equipment using water as the separating medium, is equal to the probable error, divided by the specific gravity of separation (from the distribution curve) minus the specific gravity of the separating medium. Imperfection factor thus, supposedly, corrects for the increase in probable error and results in a numerical figure that characterizes a particular cleaning device regardless of the separating density.

Hydrocyclone Performance

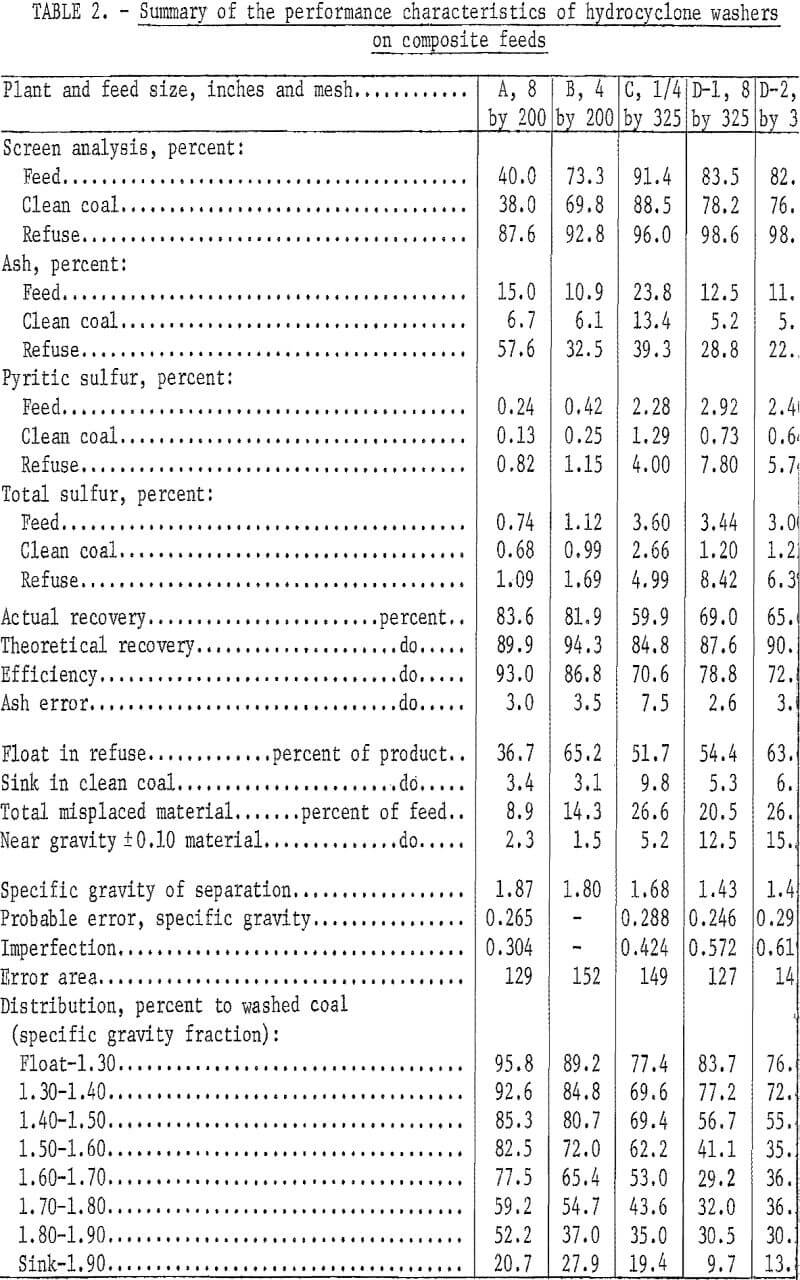

A summary of the performance characteristics for the composite plus 200- or 325-mesh material from the five hydrocyclones sampled is given in table 2.

The more notable characteristic of these summary data is the large percentages of misplaced material, especially the amount of clean coal reporting to the refuse product. The smallest amount of misplaced coal in the refuse product was 36.7 percent in plant A. All the other separations showed at least 50 percent of the refuse product was misplaced coal.

The composite clean coal products contained from 3.1 to 9.8 percent refuse (sink) material. Although this is much better than the refuse product, it may be desirable in some instances to rewash the clean coal product or some portion of it.

The distribution data, which shows the percentage of material in the feed reporting to washed coal by specific gravity component, indicate that large percentages of both the float 1.30 and sink 1.90 specific gravity fractions are misplaced.

The composite error area values ranged from 127 to 152. The efficiencies ranged from 70.6 percent for plant C, where the yield was only 59.9 percent, to 93.0 percent for plant A, where the yield was 83.6 percent.

The feed to the hydrocyclone in plant C contained 37.2 percent solids (table 1), which undoubtedly accounts for the impaired performance of this unit.

Data for the individual performance studies by size increments are given in the appendix in tables A-6 to A-10. The classification effect in the hydrocyclone is quite apparent. Characteristically, the coarsest size material provides a very low-ash, low-sulfur, quality product at a low yield and a poor efficiency. As the average particle size decreases, the specific gravity of separation increases rapidly, resulting in higher recoveries of lower quality material. The recovery of minus 100 mesh size material was generally in excess of 90 percent except, again, in plant C where the clean coal recoveries increased at a moderate rate with a decrease in size of material, attaining a maximum of only 80.0 percent recovery on the 100 by 200 mesh size material.

Plant D offered a unique opportunity for comparing two sets of hydro- cyclones that were operated under equivalent conditions with the exception of the included angle; unit D-l had a 75° angle at the apex, and unit D-2 had a 60° angle.

Comparison of the performance characteristics of the two banks of hydrocyclones shows that the 75° apex angle cone provided a lower ash and sulfur content total product at a higher recovery. Also, the composite error area was smaller for the flatter apex angle.

The specific gravity of separation was higher in the 75° cone for sizes coarser than 100 mesh as well as for the composite of all sizes.

The near gravity ±0.10 material was quite low for the first three cyclones tested. The low specific gravity of separation at which plant D coal was washed resulted in high percentages of near gravity material; however, the resulting washing performance for the plant D hydrocyclones was not adversely effected.

Conclusions

The single-stage hydrocyclone coal washer can be operated to provide a clean washed coal product; however, the underflow product in the plants sampled contained 37 to 65 percent misplaced material, making a retreatment of this product necessary to reclaim lost coal. Reputedly, the hydrocyclone can be adjusted to provide an acceptable underflow product; however, the overflow product would then require retreatment to remove heavy impurities.

The sharpness criteria values for error area and probable error were quite poor. The error area values ranged from 127 to 152, and the probable error values ranged from 0.246 to 0.297. The range of imperfection values was scattered so widely that the use of this criteria of washing performance was rendered invalid.

The size classification effect in hydrocyclones is quite pronounced, the specific gravity of separation increases very rapidly as the particle size consist of the feed becomes finer.

With hydrocyclone feeds as coarse as those reported here, the reduction of ash and pyritic sulfur in the minus 100-mesh material is very small.