Supposing that a claim is suitable for hydraulic sluicing, the first thing to do would be to ascertain what is the probable volume and pressure of the water supply. This can be closely approximated by means of an aneroid survey. The facilities for the disposal of the tailings should next be ascertained. As mentioned before, this point is of great importance, and one on which too much stress cannot be laid. The area for dumping must be such that not only is there room for the whole amount of material to be removed, but an allowance must be made for an increase in bulk that may be as much as one-third to one-half greater. The final consideration of this question should be left until after the survey has been completed, but a preliminary reconnaissance is advisable to ascertain what facilities for dumping there may be. If there are large flats in the vicinity lying below the deposit, these should be secured. Deep ravines or sloping hillsides also make good dumping ground, and of course a strong stream is one of the best of places; but care should be taken to ascertain if any future damage to others involving heavy lawsuit expenses may ensue.

If a river is to be utilized, it must be ascertained whether it can carry away the tailings, or whether it will back-up and flood the workings themselves, or valuable land, houses, or gardens. If the river will carry the tailings, it must be ascertained whether there is a likelihood of floods depositing the refuse on valuable land; or if there be a harbour at the mouth, whether it is liable to be silted up. If hillsides, ravines, or flat land is to be used, it should be ascertained if the tailings may flow over roads or good land, and the probable cost of compensation or embanking the material must be considered. After these points have been well thought out, the prospecting of the deposit and the survey of it should be undertaken. As the calculations of the probable profit are based on these two factors, too much care cannot be taken to verify these particulars. They can be undertaken simultaneously, for it is supposed that sufficient prospecting has been done to give a fair assurance that the deposit is payable. Prospecting an alluvial deposit is now generally done by boring. Sinking shafts and driving headings from them is preferable, but is generally so costly that enough of them to thoroughly test the deposit cannot always be afforded, while boring has now been brought to such perfection, and the operators are so skilful, that considerable reliance can be placed on the results obtained.

Boring should be done systematically, preferably on a series of parallel lines across the lead, the holes being put down at equal distances apart, and as close as funds will permit. The holes, on consecutive lines, should be mid-way between the holes in front and behind, as by this means as much ground as possible is explored. The holes should be carried far enough into the bed rock to make sure that it is not a false bottom nor a loose boulder.

The drawback to boring is that great caution has to be used in estimating the values per cubic yard in the material taken from the bores.

It is best to put all the material taken from the bores into a measured box, from which the mass can be ascertained, due allowance being made for the increase of bulk over the material in situ.

If the cubic contents of the bore-holes be calculated, and the values recovered apportioned to this, grave mistakes may occur, owing to the material falling in from the sides of bores giving a larger quantity of sand than has been calculated. The bore-holes should be plotted, the length, breadth, and depth of the deposit ascertained, and the values correctly distributed.

If there is a basalt or conglomerate capping, it may be very expensive to bore, as shafts would have to be driven through the capping for each bore-hole. However, if much capital is to be spent, it is better to lose part than the whole, and if the prospecting is not properly done it is impossible to estimate the value of the deposit.

Simultaneously with the boring the survey should be carried out, and should be conducted with equal care. It should be done by a competent man, especially if the bringing in of, a water supply threatens to be difficult. Much money may be wasted by an incompetent man in this class of work without it being easy of detection, and the water supply greatly diminished in quantity and pressure, with the possibility of a race breaking away, causing loss of, time, money, and law costs for damage to property.

The points to be ascertained by the surveyor are:

- The minimum quantity of water obtainable in the source of supply. If the minimum quantity is not sufficient, the best site for a dam to form a reservoir must be ascertained and surveyed.

- The highest point above the mine that the supply of water and the character of the country will permit the water to be brought in at.

- The nature of the ground through which the race will pass, so that its grade and shape may be determined.

- The reduced level of all the bore-holes, so that the lowest point in the deposit may be ascertained, and any other measurements or levels that may be necessary to calculate the total cubic contents of the deposit.

- The area and levels of any dumping ground, to ascertain if there is sufficient room, as well as how it is situated in regard to the lowest part of the deposit.

If water from a high level is not obtainable, it may be necessary to use water at a low level, in which case a careful estimation must be made of the cost of pumping to a service reservoir; elevated tanks; or pumping direct through the pipes, as the case may be, and it is quite possible to find situations where this may be as convenient as long and costly races.

When the survey and boring are finished, and the length, breadth, and depth of the deposit, the average supply of water during the year, and the area of the dumping ground ascertained, an estimate can be made of the total cost, which, with the cost of working and that of conveying the tailings to the dump, will enable a calculation to be made of the probable profit or loss on working the deposit.

Any venture, mining or otherwise, to be profitable, must pay back the capital invested in it, the cost of working, together with a profit which should not be less than what money can be lent for on good security, and in mining should be considerably more, to compensate for the increased risk. If, then, with reasonable accuracy, we can calculate the profit, we will be in a position to judge whether it is sufficiently above any other more certain investment to pay for such risk. To calculate in what time the deposit will be worked out, it is necessary to know how much material can be removed by the water available, and this cannot be stated unless the nature of the material and the grade of the tail race be known. From the statistics of 82 claims examined, an average of 31 units of water to 1 of material removed was obtained, but this information was very vague as to grade of tail races and quality of material. The grades examined varied from 2 to 4 per cent., or 1 in 50 to 1 in 25, and the water duty varied inversely from 18 units of water required to move 1 unit of sand for a 4 per cent, grade (1 in 25) to 56 units of water to 1 unit of sand for a 2 per cent, grade (1 in 50). For a disintegrated granite, with 3 per cent, grade (1 in 33½) of tail race, 40 units of water to move 1 of sand could be taken as fairly safe, but in all cases like this the advice of an expert should be sought, and even the advice of an expert should be received with caution, as little is known of the ratio of grade to carrying power of races.

In the following hypothetical calculation, the water duty will be taken at 40 to 1 on a 3 per cent, grade. The cost of the main race is taken at £45 per cubic foot of water per second per mile, which is rather high, but is quoted from an actual case. The deposit contains 1 million cubic yards of material at a value of sixpence per cubic yard—say the head race is 10 miles long, and will carry 10

Allowing a water duty of 40 to 1, 10 cubic feet of water per second will move 800 cubic yards a day of 24 hours; therefore 1 million cubic yards of material, divided by 800 cubic yards removed, is equal to 1,250 working days of 24 hours.

As the deposit will be worked out in 1,250 days, the capital must be paid back in that time; therefore £6,785 divided by 1,250 equals £5 8s. 6d. per day. Taking working expenses, which include rent and office expenses, at threepence per cubic yard for 800 cubic yards equals £10 ; and 800 cubic yards moved per day at sixpence per cubic yard equals £20 of values won.

Allowing 280 working days to a year, the deposit would be worked out in 4½ years.

If the capital had been invested at 5 per cent, compound interest for 4½ years, which may be taken as the interest on a reasonably safe investment, it would have returned £1,662. On the venture under consideration, the value returned in the same period, after paying back the capital and all running charges, would be £5,712, which is equal to compound interest at about 13 per cent, on the capital invested, which may be considered a reasonable interest for the risk undertaken.

In the above no account is taken of the assets at the end of the period, such as the race, tools, houses, &c., which may or may not be in good condition, as they would help to increase the profit instead of diminishing it, and also no account has been taken of the cost of boring, surveying, and flotation expenses, all of which must be added to the capital expenditure, but which have not been added in the case under consideration, because of the difficulty in arriving at a correct estimate.

If, however, there be overburden on top of the drift the cost that each yard of drift must bear will be increased; and, as a rule, a certain proportion of the overburden must be stripped off before the drift can be attacked. Consequently the drift when worked must pay back a capital greater than the actual amount spent on races, pipes, surveying, boring, &c., by the amount spent on working costs while removing such overburden, together with the interest on the money spent on erection of plant and working costs during that period.

Let us take a hypothetical case with 1,000,000 cubic yards of drift in it as before, but in addition 500,000 cubic yards of overburden.

The rate at which the overburden will be removed varies enormously according as it is hard or soft, the grade of the race steep or flat. The water duty, 190 to 1, which will be taken in the hypothetical case, is from an actual case in New Zealand, the material being hard cemented gravel with large boulders, and the grade of the race 1 in 20.

The drift will be valued at 1s. per cubic yard and the cost of removing the overburden at 9d.

The amount of water will be taken at 20 cubic feet per second. The whole of it will be used on the overburden while it is being removed before drift sluicing commences; afterwards it will be divided equally between drift and overburden.

In the case under consideration it will be considered necessary to remove 60 per cent, of the overburden before work on the drift can be commenced, otherwise the drift cannot be removed at the rate of 800 cubic yards a day during the whole period of its working.

Duty on drift taken at 40 to 1 on a 1 in 33 grade.

Duty on overburden taken at 190 to 1 on a 1 in 20 grade.

Sixty per cent, of the overburden equals 300,000 cubic yards.

Drift is removed at the rate of 800 cubic yards a day, with 10 cubic feet of water per second.

Overburden is removed at the rate of 336 cubic yards a day with 20 cubic feet of water per second, and at the rate of 168 cubic yards a day with 10 cubic feet of water per second.

300,000 cubic yards of overburden divided by 336 (the quantity moved per day) equals 892 working days, which, allowing 280 working days to the year, equals three years nearly.

The cost of races, pipes, nozzles, &c., will be taken at £13,000, and it will be presumed that they take one year to erect. As the money is not paid out in a lump sum at the beginning of the year, but is spread through the year, interest on that amount will be reckoned for 3½ years at 5 per cent.

The drift must therefore pay back, besides the working expenses incurred for the removal of itself and the rest of the overburden, together with a profit.

There are left 200,000 cubic yards of overburden and one million yards of drift.

The overburden at the rate of 168 cubic yards a day will be worked out in 1,190 and the drift in 1,250 working days.

Therefore each day’s output of drift must stand 1190/1250 = .952 of the cost of each day’s removal of overburden.

This gives a profit at the rate of 3% only.

The following points should be observed in regard to head races:

- The water should be brought in at the highest elevation that the supply and the character of the country will permit of. It is important to bear this in mind, as the force with which the water strikes the face is directly as the pressure it is under. Now, the water running in the head race has no pressure, and useful pressure arises only when the water is confined in a pipe. The head race should therefore be laid out with a view to obtain the utmost pressure in the pipe. The vertical height of the inlet of the pipe above the outlet is called the hydraulic head. Each foot of this head has a pressure of 0.433 pounds on the square inch. Thus, if the tank at the head race, which is the inlet of the pipe, be 300 feet above the outlet of the pipe, there is 300 feet of head, or a pressure of 130 pounds on the square inch, available in the nozzle. The passage of water through a pipe is subject to the friction of the sides, which has the effect of diminishing the discharge, and for the same head the longer the pipe the greater the friction. It is therefore of importance to have the pressure pipe as short as possible, and to avoid as far as may be any deviation from a straight line between the inlet and the outlet. As the friction depends entirely on the velocity of the water, the larger the pipe the less loss of head there is from friction.

As an example of how the quantity of water delivered is decreased and the head or pressure reduced by increased length and diminished diameter of pipes, the following case will show:

(а) A pipe 300 feet long and 5 inches diameter is discharging 300 gallons a minute. The loss of head in overcoming the friction is 11.85 feet, which is equal to 5 pounds pressure on the square inch, so that the inlet of the pipe must be at least 11.85 feet above the outlet, or less than 300 gallons a minute will be discharged. A pipe of 10 inches diameter, of the same length and discharging the same quantity of water, would require the inlet to be only 3.7 feet above the outlet—that is, it would need only 3.7 feet of head, or 1.6 pounds pressure on the square inch, to overcome the friction in the pipe of 300 gallons of water per minute.

(b) A pipe 300 feet long, 5 inches diameter, with 100 feet head, or 43.3 pounds per square inch, will discharge 870 gallons a minute but a pipe of the same length, 10 inches diameter, will discharge 5,000 gallons a minute.

A pipe 300 feet long, 5 inches diameter, discharges 870 gallons,, but the same pipe 3,000 feet long will only discharge 275 gallons a minute.

- Where it is consistent with economy, fluming and all timber work should be avoided, as it is perishable and costly to keep in repair.

- In loose sideling ground fluming as against ditching must be considered, for the extra cost and maintenance of fluming may be trifling compared with that arising from slips, loss of water by leakage, stoppage of the works, or compensation for injury to-others by a break away of the water.

- Where a long spur has to be turned, the cost of tunnelling as against taking the race round should be carefully considered, especially as, apart from the question of cost, there may be a considerable gain of height by the shorter length of a tunnel—for instance, a race having a fall of 10 feet to the mile going round a spur 2 miles long would have a difference of level between the two ends of 20 feet, whereas by tunnelling half a mile through the spurs there would be a difference of 5 feet only, a saving of 15 feet of head available for pressure at the mine.

- It is advisable to secure all watercourses along the races, to make up for evaporation, absorption, and leakage.

- By-washes for the escape of flood water should be provided at suitable intervals, taking care that the water will pass down a natural watercourse and not cause damage to low-lying land.

In dry, hot countries the loss in a long race from evaporation should not be neglected in calculating the quantity of water a race will deliver. Deep and narrow races lose less by evaporation, and are cheaper to cut, but are apt to scour badly, and are only fit for hard country. The loss by absorption is generally in excess of all other losses; it is often corrected by puddling clay into the running water, and in some cases sand is used with great effect in loose gravelly soil.

The costs of races depends on their size and the character of the country, but the cost of some in America quoted by A, J. Bowie may be interesting:

- North Bloomfield.—Top width, 8 feet 6 inches; bottom, 5 feet; depth, 3 feet 6 inches; delivers 80 cubic feet a second ; cost, £1,697 a mile, which is equal to £21 4s. per cubic foot per second per mile.

- Milton.—Top width, 7 feet 6 inches; bottom, 4 feet; depth,. 3 feet 6 inches; delivers 75 cubic feet a second; cost, £1,740 a mile, equal to £23 4s. per cubic foot per second per mile.

- Hendriks.—Top width, 5 feet; bottom, 5 feet; depth, 2 feet; delivers 26 cubic feet a second; cost, £585 12s. a mile, equal to £22 12s. per cubic foot per second per mile.

- La Grange.—Top width, 9 feet; bottom, 6 feet; depth, 4 feet; delivers 60 cubic feet a second; cost, £4,500 a mile, equal to £75 per cubic foot per second per mile.

The cost of fluming or ditching cannot safely be quoted, as the conditions vary so much.

Experience seems to show that when, as is often the case, the life of an alluvial mine is limited to a few years, the system of pumping direct to nozzles, involving a moderate first cost, will compare favourably with a natural gravitation water supply brought into the mine by a race probably many miles long, and involving a large capital expenditure.

The introduction of the modern high-lift centrifugal pump, with an efficiency of 75 per cent, at heads of 200 feet, and driven by high-class engines of great economy, will considerably strengthen the case for steam power, as, under favourable conditions, it ought to be possible to reduce the annual cost of a horse power to about £21. Taking the duty of water at 40 to 1 in ordinary gravel or drift, and the water from pump at 8 cubic feet a second would give 6½d. for water only, and, allowing 3d. for all other charges, gives a total cost of 9½d. per cubic yard. Taking the value of the machinery and plant at £4,000, and the quantity of the deposit at 1 million cubic yards, then the amortization charge is 1d., and the total cost amounts to 10½d per cubic yard. If, in the case stated at page 38, the race had cost £35,000, then the cost of treating the material would be about the same in each case; but in many cases the first cost must be low even if it means higher working expenses, and it may be possible when the deposit is worked out to either sell the machinery or to remove it to another claim. The merits of the two systems must be decided for each individual case, and an abstract opinion is impossible.

The next question to consider is the metal-saving equipment.

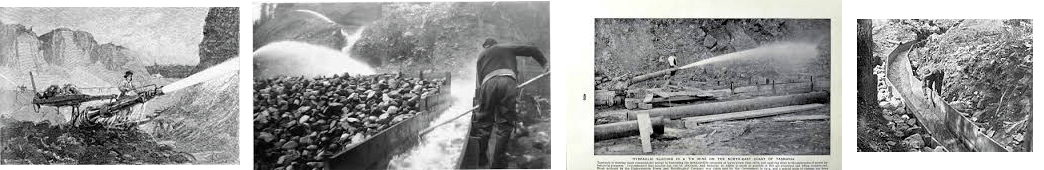

In hydraulic sluicing the most usual way is to make use of the difference in the specific gravities of the metal and the gangue, and some form of sluice box is usually employed. Amalgamation in the boxes is extensively practised in America, but not so extensively in Australia.

The separating of materials by means of their different specific gravities is a very common one in mining, and in most cases much thought and many careful experiments have been devoted to the question. The grade of the inclined planes, the quantity of water used on them, their superficial area, the depth on them of both the sand and the water, and the ratio of the sand to the water, all have an effect on the success of the operation, and have been carefully studied by men of trained minds and long experience. It is to be regretted that such care has not been exercised in the case of hydraulic sluicing, and there has been a general tendency to walk in the beaten path of custom. This has been owing more to the peculiar conditions than to any want of intelligence on the part of the operators, but now that deposits are no longer so rich as they once were, it behoves operators to pay more attention to this detail.

In gold sluicing, as a rule, long lengths of sluice boxes are used, which serve the double purpose of saving the gold and removing the tailings. The bottom is provided with obstructions in which the gold may lodge, and the want of any rule as to grade, quantity of water, &c., is sought to be compensated for by the great length of the boxes. In some cases an improvement has been made by putting in wide shallow boxes, known as “ under currents,” which greatly reduce the rate of flow of the water, and allow the fine gold to settle. In America wide tables are often used, in which some attempt has been made to reduce the practice to a system.

The theoretical grade for the box, and depth of water flowing over it, is, of course, that at which the particles of gold just settle. This would allow the maximum of material to be treated. This theoretical perfection is unattainable, chiefly owing to the different sizes of the particles, but a few experiments to ascertain the best that can be obtained under the conditions are well worth carrying out. In gold sluicing the object is to keep the layer of sand moving over the ripples so thin that the particles of gold can work through it and be caught. Once caught in the ripples they cannot escape, But if the ripples themselves be covered with sand which is not in motion, the gold particles can no longer pass through it, but will come to rest, and there they will remain as long as it does not move. But if by any chance the quantity of sand fed into the box is diminished, the water having now less sand to carry will begin to act on the sand already at rest, and will remove both it and what gold there may be with It. It is for this reason that wide shallow boxes are preferable to narrow deep ones, as the sand, being spread out in a thinner sheet, permits the gold particles to more easily penetrate it. It also accentuates the care that should be taken to keep the ratio of the water to the sand as much the same as possible. Long sluice boxes, however, often are of use for disintegrating the material, and the boulders that roll along with it clean and polish the gold, making it more susceptible to the action of mercury where it is used.

The principle of using narrow boxes, set at a steep grade, with no provision for arresting fine gold, should be distrusted, for, although coarse gold, and even fine gold, is hard to lose even by the most skilful mismanagement, there are so many cases that can be quoted where handsome profits have been made out of the tailings, which could have been reaped by the original investors if a little more care had been exercised, that it should be distinctly shown that there is no fine gold present, or that it does not pay to save it. Of course, the latter is the chief question, to which all others are subordinate, and so much depends in many claims in getting quantity through that it often does not pay to save all the gold.

The saving of tin ore is quite distinct from that of gold, and the two methods should not be confounded, for, although gold can be saved in a box suitable to save tin, the reverse is not the case. In treating bulky material like tin ore it would be impossible to catch it in the ripples of a gold sluice unless a very extensive surface were .provided. The extent of surface that would hold a very high value of gold would hold a very small one of tin.

The principle on which tin-saving is based is that when sand and water flow down an inclined plane in such a ratio of sand to water that the lowest layer of sand will just come to rest by reason of its friction against the bottom, or against the sand deposited on the bottom, the tin, by reason of its greater weight, will work through the moving sand until it comes to rest, when it will become covered with another layer of sand, and will stay there as long as it is so covered. This deposition will not go on evenly throughout the length of the box, but will be greatest at the head, where the material first enters. Consequently the slope down which the water flows will be steepest at the head; the current will become swifter and swifter as the grade rises, until there will be no more deposition at that place, but at some place lower down, where the grade has not become so steep. It is evident, then, that this sand and tin will gradually move down the box until the whole of it has such a grade that neither the sand nor the tin will be deposited, but will run on to the dump heap.

If slats of wood, called ripples in tin sluicing, are placed at intervals across the box, they will prevent the layer already at rest from moving any further, and the same process will go on on top of this layer until the box is full of sand and tin, when it must be cleaned out. This is done by removing a ripple, turning on clean water, at the same time shovelling the sand against the stream; when the tin, which naturally moves more slowly by reason of its weight, is kept back, while the lighter sand flows away, and by this process the tin can be worked down to the bottom of the box comparatively free from sand.

From the above the necessity is seen of keeping an even feed; if the feed is too thick, sand will be deposited more quickly at the head, and so raise the grade there; if now the feed falls off, the comparatively clear water will begin to scour out the sand, and with it the tin, which effect will continue until the velocity of the water is so reduced by the flattening of the grade that sand will begin to be deposited again. If clear water with no sand is kept running, this scouring will go on until the whole of the sand and tin is removed.

The above methods are used where very long boxes can be put in. If the box is short the constant cleaning out becomes a costly operation. To overcome this difficulty extent of surface is gained by increasing the width of the box. But in a wide box it is difficult to keep the water spread evenly over the box and prevent it from cutting channels. Another method is therefore used; high ripples are put in, reaching almost to the top of the box, sand and water is turned in, the tin sinks by reason of the decreased velocity caused by the ripples, and a considerable quantity of sand goes away. When the box is filled to the level of the top of the ripples, and the tin is seen getting back towards the tail race, the feed is stopped, clear water is turned on, and the material kept turned over by shovels. The tin sinks through the sand for a certain depth, a ripple is removed, and the top layer of sand run off; a similar process sinks the tin still deeper, until it is collected in one layer on the bottom. The ripples are then put in again, and the feed turned on until it is necessary to again run down the box to sink the tin. This process can be repeated until the tin rises to the level of the top of the ripples, when it is necessary to clean out the

box.

The last point to be considered is the tail races for removing the material to the dump, which may or may not be used for saving the metal. The best possible site for a dumping ground having been selected, the survey will show their length and the grade at which they can be brought in, and it must be remembered that the steeper the grade of the race the more material it will remove, other things being equal; therefore, given adequate metal-saving equipment, the faster the deposit will be worked out, for the same number of men and the same quantity of water employed.

Certain factors, however, put a limit on the grade of tail races. If the dumping area is restricted, what is wanting in area must be gained by height; the outfall of the race must therefore be as high as possible, consistent with allowing enough grade to work the deposit at a profit. For instance, in our hypothetical case, on a grade of 1 in 33, with 10 cubic feet of water per second, 800 cubic yards of drift would be moved a day, giving a profit of £4 11s. 6d. a day. But if the grade of the race be flattened to 1 in 50 a water duty of only 56 to 1 would be obtained, giving 571 cubic yards moved per day, of a gross value at 6d. per cubic yard of £14 6s., which, as the expenses are £12 11s. 3d., gives a profit of only £1 14s 3d.

It is most essential for the cheapest working that the tail race should be brought in low enough to command the lowest point of the deposit; for, if not, pumping or some form of elevating the material, will have to be resorted to. Water may be so plentiful that, after taking the amount necessary for elevating the material, there may still be enough to remove sufficient drift to make the proposition payable; but, of course, with less water less drift can be removed, other things being equal, and therefore less profit per day obtained.

Again, after removing enough water to elevate with, there may not be enough left to work the drift at a profit. In our above-stated case, if 2 cubic feet per second of water be taken to elevate with, only 8 cubic feet would be left to sluice drift with, leaving a profit of £2 11s. 6d. per day. If 3 cubic feet were taken, leaving 7 to sluice with, the profit would be reduced to £1 12s.

If, however, the race to tap the lowest point of the deposit has to be brought in at so flat a grade that enough material to make a profit could not be put through it, it might pay to have the inlet above the lowest point of the deposit, and to elevate to it. For instance, if,only 400 cubic yards a day could be put through, there would be a daily loss of 8s. 6d., but by bringing in the race at a 3 per cent, grade, and taking 3 cubic feet of water for elevating, there would be a profit of £1 12s.

These points must all be decided before the grade of the race is settled, but as soon as this is done the length and size of the race can be calculated and added to the rest of the computed expenditure.