Table of Contents

The method of working by Hydraulic Mining consists, as has been already stated, in breaking down banks of gravel by the impact of powerful jets of water, and passing the disintegrated material through a line of sluices, without the agency of hand labour. The chief requisites for the successful application of hydraulic mining are:

- Large quantities of auriferous gravel, not less than 30 feet in thickness, and not overlaid by any appreciable thickness of barren material, which would necessarily be passed through the sluices with the pay-dirt. The gravel treated need not be rich, a mean yield of less than 1 grain of gold per cubic yard being often enough to furnish profits if the operations are on a sufficiently large scale.

- A plentiful and uninterrupted supply of water throughout considerable portions of the year.

- Sufficient fall in the ground so that (a) the water may be delivered under the pressure of a head of from 100 to 300 feet, (b) the tailings can be easily carried away to a large dumping ground, which is most conveniently, either the sea or a large and rapid river.

History of Hydraulic Mining Operations

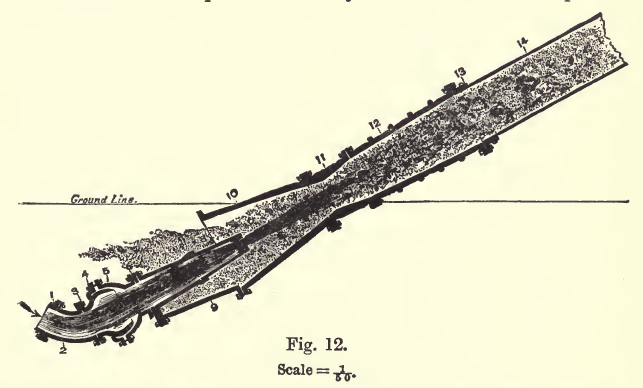

In California, the naturally occurring banks or cliffs in the gravels in the sides of the gulches were first selected for attack. Later, some of the deposits occurring in those channels which are not intersected at favourable points by the present system of drainage were operated on. It is necessary in such cases to run a tunnel from the nearest canon in the bed-rock to the lowest point in the gravel, this point being found or guessed at by prospecting operations. The tunnels are often of great length, that at the North Bloomfield Mine, Nevada Co., Cal., for example, being 7,874 feet or 1½ miles long. One or more shafts are then sunk from the surface through the gravel to the tunnel, and washing operations are begun by ground- sluicing, letting the water and gravel fall down the shaft and run through the tunnel, in which the sluices are sometimes laid. The surface near the shaft is thus gradually lowered, or it may be terraced by hand labour, until an excavation is made of sufficient size to enable the ground to be attacked with the hose. Washing then proceeds regularly in this manner, the bank being broken down by jets of water, and the products being allowed to fall down the shaft and pass through the tunnel.

Hydraulic Mining Water Requirements

The amount of water required by large undertakings is far more than can be obtained from the rainfall on the hills immediately round the mine. Thus the North Bloomfield Mine, in the season of 1877-8, used between sixty and seventy millions of gallons per day, or enough for the total supply of a city of three million inhabitants. The workings, moreover, must necessarily be considerably above the level of any large rivers in the neighbourhood, so that it is often necessary to construct huge reservoirs at convenient spots to store up the rainfall and melted snows of large districts, and to convey the water thence to the mine by ditches, flumes, or pipes. Wooden flumes are cheaper than ditches, but are more liable to be damaged. Sheet-iron pipes are made as much as 30 inches in diameter, and are cheap, durable, and easily repaired; they entirely prevent losses by leakage and evaporation, and deliver more water under similar circumstances than flumes, as they offer less frictional resistance to the flow.

Where it is necessary to cross side canons or gulches the flume or iron pipe is carried over on a light trestle bridge, or the water is passed through an inverted siphon formed by a wrought-iron pipe which passes down one side of the valley and up the other, being filled from a head-box or reservoir, and delivering the water at a lower level on the other side. At Cherokee, Butte County, an inverted siphon pipe is used to carry the water across a ravine 873 feet deep. The diameter of the pipe is from 30 to 34 inches, and its greatest thickness (where there is a pressure of 384 lbs. per square inch) is 0.375 inch. The Miocene Ditch Company, operating in the same County, carried their flume, of 4 feet wide and 3 feet deep, round the face of a bluff 350 feet high, supported on L-shaped iron brackets made of bent T rails, soldered into holes previously drilled by men let down the face of the cliff by ropes. Successful ditch construction often depends on such engineering feats.

The water is delivered at a convenient height above the workings into a “pressure-box,” consisting of a small wooden reservoir from which the pipes take their origin. In many cases the reservoirs and ditches are owned by separate companies, or, as in New Zealand, by Government, and the water is sold to the miners by measure. The unit in New Zealand is a “government head,” and in the United States a “ miner’s inch,” following the system in vogue in Spain and Italy. The amount of water that will flow through an orifice 1 inch square, cut in a board of 1 inch thick, under a head of water that varies with the custom of the locality, but is usually from 4 to 8 inches, is called a miner’s inch. The amount of flow in twenty-four hours is called a “twenty-four-hour inch,” and similarly there are ten- hour and twelve-hour inches. The quantity of water in a miner’s inch varies with the head of water used and the form and size of the orifice for delivery. Thus the amount delivered from an orifice 25 inches long and 2 inches wide is reckoned as 50 inches, although it will be more than fifty times as much as the delivery from an orifice 1 inch square. The twenty-four-hour inch under a head of 7 inches amounts to about 2,230 cubic feet.

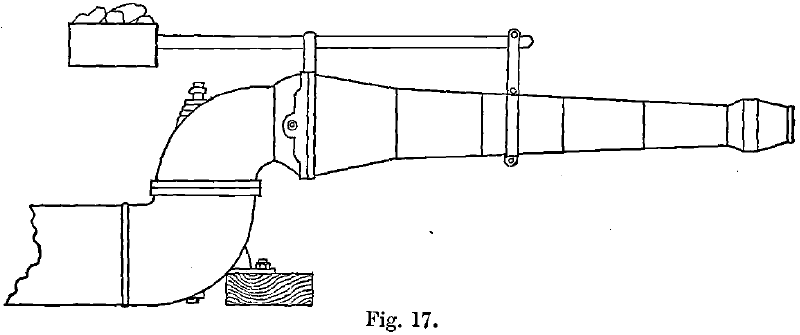

The water is conveyed from the pressure-box by pipes, which were formerly made of canvas hose, to which iron rings 3 inches apart were added for pressures of over 100-feet head. They are now made of sheet iron. The iron feed-pipes are made from 10 to 15 inches in diameter, and the thickness varies according to the pressure which they may be called on to withstand. Sharp bends in them are avoided, as the flow of water is checked thereby. They are liable to collapse if the level of the water in them is reduced, and a partial vacuum formed inside; hence, as in the case of all other sheet-iron pipes used in hydraulic mining, they are fitted with valves, which are constructed so as to freely admit air from without. The water is discharged through a nozzle called a “giant” or “monitor” (Fig. 17). The nozzle was at first a sheet-iron tube, having an aperture 1 inch in diameter, and was held in the hand. The size of the nozzle was gradually increased, until it reached a diameter of 11 inches. Such a stream, under a head of 200 feet, requires special appliances to control it, deflect it at will, and prevent the nozzle from “ bucking.”

Breaking Down the Bank

When the jet is first directed against the bank, the water spatters in all directions, then buries itself a little, and after a time, in loose ground, a “cave” takes place, the undermined bank falling down. By the method of undermining, the power of the giant is much increased, especially where hard and soft layers alternate. When large caves are about to take place the water is turned off, as otherwise the ground may run so far as to overwhelm the monitor and the workman directing it. The nozzle is placed as near to the bank as possible, consistent with the safety of the workers, so as not to waste too much of the initial velocity of the stream of water. Consequently, lofty banks are not advantageous, and if they exceed 200 feet they are usually worked in terraces of 100 feet or so in height. In some parts of the Spring Valley Mine, however (see Fig. 18), a bank of 450 feet high was worked in a single bench, and it was then not unusual for the runs of ground to bury pipes which were throwing 7-inch streams from a distance of 400 feet from the face of the bank.

The jet is, if possible, delivered unbroken against the face of the bank, as its disintegrating power is thus kept at its maximum. However, in some cases, where it is cemented, the gravel is too hard to be economically broken down by the water alone, and blasting is then resorted to, a drift being run into the bank, and cross-cuts made at the end in which the powder is placed; the drift is then filled up, and the charge exploded by electricity. It is more economical to blow out the base of the bank, as the upper part then falls by its own weight and can be broken up by the water. Sometimes arrangements are made to explode very large blasts: thus, at the Blue Point Mine, Nevada County, a charge of 50,000 lbs. of powder was exploded in cross drifts at the end of a main drift 325 feet long in the year 1870, and 80,000 cubic yards of gravel were brought down, while at another mine, 3,500 lbs. of dynamite were exploded in 1872, and 200,000 cubic yards of gravel thrown down.

Hydraulic Mining Pros and Cons

Both in California and Australia, when the first gold discoveries were made, the river beds and bars were at once explored, and soon afterwards the flats closely adjoining them. Subsequently, the bench gravels situated in the same valleys, and the side ravines and gulches, which remained dry during most of the year, were prospected and worked, owing to the rapid growth of the mining population and to the fact that the exhaustion of the shallow placers was already beginning to make itself felt. The result was that the exposed edges of the outcrop of some of the deep leads were found, and the pay-dirt followed into the hill-side by drifting. Then, as in many cases it was found that the gravels overlying the pay-dirt on hill-sides, although poor by comparison with the earth below them, nevertheless contained a small quantity of gold, the idea was evolved of breaking down the whole bank by jets of water, and passing all the material through the sluices. Hence arose the practices of drift and hydraulic mining, of which the former is largely used in California, while the latter was much used in California prior to 1884 and in New Zealand and throughout the Western States of America, but cannot be applied in Australia or Siberia owing to the general flatness of the country. In Siberia, only shallow placer deposits are worked. In Australia, the deep leads are usually reached by shafts, since the surface of the country is not intersected by deep canons, as in Western America. Drift and shaft mining of deep leads will not be further referred to in this volume, attention being confined to the treatment of the gravel after it has been raised to the surface. In hydraulic mining, the breaking down of the gravel is so intimately connected with the extraction of the gold that a short description of the whole process is given.

Hydraulic Mining Equipment

In this machine a jet of water under high pressure forces water, gravel, and boulders up an inclined plane, and delivers them all at the head of the sluice, which may be as much as 100 feet above bed-rock. The differences in construction between the machines made in Australia, New Zealand, and the United States are only matters of detail.

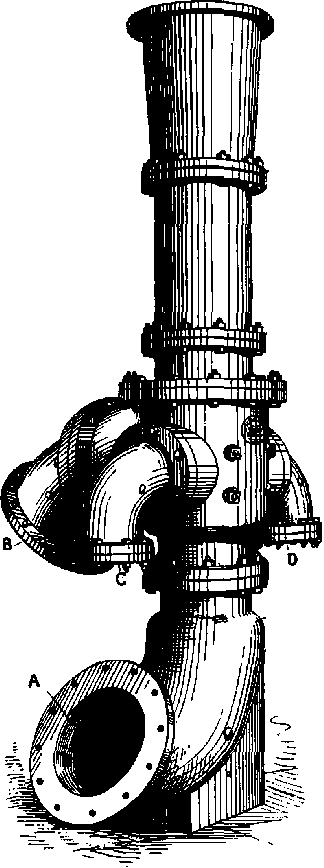

They consist essentially of an upraise pipe, usually of wrought iron, having a diameter of from 12 to 24 inches, which terminates below in an open conical funnel; a hydraulic nozzle, delivering water under the pressure given by a head of from 100 to 500 feet, projects into this funnel, and sand and gravel can also enter round the sides or through a special orifice. The inclination of the upraise pipe is usually from 45° to 65°. The top of the upraise pipe is turned over and terminates above a sluice, into which the gravel falls and is washed in the ordinary way. The Evans elevator made by the Risdon Iron Works, San Francisco, is shown in Fig. 20. A is the orifice through which the water for the jet is forced, B the main suction opening, and C and D two auxiliary suction openings, which can be connected with pipes of any length and serve for raising water or fine material. The upraise pipe is now generally made with heavy steel plate, and the elevator itself of cast steel, instead of cast iron, the weight being much reduced in this way. The supply pipe is greatly contracted at the throat whence the jet of water issues. The nozzle and the lower part of the upraise pump are sunk in a sump excavated in the bed-rock, and the gravel is washed down by any means (usually by a jet from an ordinary hydraulic nozzle) into this sump. The entrance to the upraise pipe is protected by a coarse grating which prevents large stones, pieces of wood, &c., from entering it. The force of water is enough to complete the disintegration of the gravel during its passage through the upraise pipe, so that a short sluice is enough to effect the washing proper. If the excavation is carefully arranged, it may be kept funnel-shaped, so that the elevator, once placed in a sump, may be worked there permanently without being moved. When the pit is large enough, the washing may be done inside it, only the tailings being raised to the surface by the hydraulic elevator. The head of water required varies according to the vertical height through which the gravel must be raised; a head of about 60 feet is required for every 10 feet of vertical upraise. Since it is just as expensive to raise water as gravel, arrangements must be made to deliver as much gravel into the sump as can possibly be raised by the jet, otherwise the expense per cubic yard will be greater, and there will be too much water with the gravel for satisfactory treatment in the sluices.

Wherever the necessary head of water is available, the hydraulic elevator is now recognised as a good method of working flat placers, river-bars, &c., or any deposits which are either below the water level of the district, or which have not sufficient fall for the disposal of the tailings by gravity. It is in wide use in California and New Zealand. The following instances of work in both countries may be given :—At the Blue Spar Consolidated Gold Mining Company, Gabriel’s Gully, New Zealand, tailings which have accumulated close to the sea on the foreshore, are sluiced in this manner. The vertical upraise is 60 feet, the angle of inclination of the upraise pipe being 63.5° ; about 480 tons of gravel are raised per shift, the head of water used being 400 feet, while the amount of water used in each elevator is seventeen government heads. The sluice is short, and has an inclination of only 3½ inches in 12 feet; the upper parts are fitted with transverse, patent -shaped, angle iron riffles, in which the angle faces up stream (see Fig. 19). The lower parts of the sluice have a false bottom of wrought-iron plates, perforated with round holes; beneath these plates is the true bottom of the sluice, Covered with cocoanut matting in which fine gold is caught. The tailings are discharged into the sea.

At Quartz Valley, Siskiyou County, California, on hard ground, where the elevator was first used, it took forty-three days to work out a piece of ground 300 feet by 250 feet, which was of an average depth of 18 feet. The bank was washed down with 600 miner’s inches of water, and went to the elevator through a 30-inch bed-rock flume, which had a grade of 5 inches in 12 feet. The water and gravel were raised through a 20-inch elevator pipe without any contraction at the throat. It was set at an angle of 40°, and the pipe was 42 feet long, the vertical upraise being thus 28 feet. The force used was 1,000 inches of water with a head of 230 feet, delivered through a 6-inch nozzle, and the gravel was emptied into a sluice 6 feet by 3 feet, with a grade of 1½ inches in 12 feet. When 3,500 inches of water were running in this sluice, they could not carry off all the gravel raised by the elevator. The work was done without any delay from stoppage of the machine, and there were no repairs, the wear of the elevator being very little.