Table of Contents

The Federal Coal Mine Health and Safety Act of 1969 specified that the average respirable dust level to which a miner is exposed during the work shift must be 2.0 mg/m³ or less as of January 1, 1973. In response, the Bureau of Mines initiated a program to develop new and improved methods of technology to control dust generation.

The use of water sprays on continuous-mining machines is a primary method of suppressing dust in the face area of an underground coal mine. Sprays have been reported to reduce the concentration of respirable dust from 20 to 60 percent. Because the type, number, and location of nozzles are often selected in an arbitrary manner, a Bureau program was initiated to obtain engineering guidelines so these factors could be adjusted to obtain optimum conditions for the suppression of respirable dust in the face area of an underground coal mine.

A Bureau field study conducted by Emmerling and Seibel reported that the amount of respirable dust that escaped the face area while cutting with a Lee Norse (LN) 26H6 continuous-mining machine using conventional spray nozzles and locations depended on whether a box or slab cut was being made and whether an upshear or a downshear cut was being used.

A second field study to determine the importance of spray nozzle type and location with a LN 26H mining machine was reported by Matta.7 A “rented” section in a moist seam was used, and the mining operations were tightly controlled to improve reproducibility. Results showed that sumping generated 70 percent of the dust formed at the face and that water sprays on the bottom of the boom reduced the sumping dust by 53 percent compared with dry operation and were 2.5 times more effective than top sprays.

This report presents the results of a third field study to determine the optimum spray characteristics for the suppression of respirable coal dust with water sprays using another ripper-type mining machine in a dry seam (2 percent moisture).

Acknowledgments

The authors would like to thank Sigmund Black and John Rounds of Ingersoll-Rand Research Inc. for assistance in conducting the experiments and gathering the data; Eastern Associated Coal Corp. for providing engineering assistance and work crew; Frank Nagy of the Bureau of Mines Dust Control and Life Support Group, Pittsburgh Mining and Safety Research Center, for assistance in instrumentation and conducting the field tests; and Ray Kacmar of the Dust Control and Life Support Group for assistance in the statistical analysis of the data.

Procedure

Research tests were conducted in the Eastern Associated Coal Corp.’s Joanne mine, Rachel, W. Va. A special research Lee Norse continuous-mining machine (LN 456) having jacks and electrohydraulic circuits for automatically operating and controlling the sumping and shearing velocities during the cutting operations was used in an attempt to improve reproducibility. In this series of tests the automatic sumping operation was malfunctioning, and sumping was done with manual control. Otherwise, the LN 456 was a conventional type of mining machine, with the cutting drum operated at 51 rev/min using plumb-bob bits with 45° bit attack angle and 2-inch bit spacing. The coal was the Pittsburgh seam, 6 feet high with 2 percent moisture, and was reasonably homogeneous. The section was operated with exhaust ventilation using line brattice. A separate brattice was maintained against the rib to smooth the airflow.

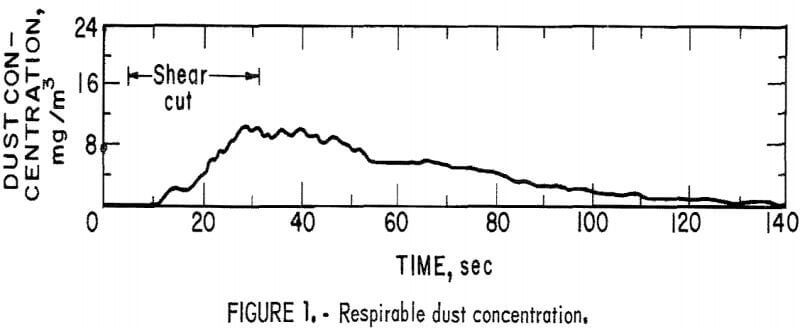

The general test procedure was to measure the total amount of respirable dust conducted to the return when the continuous-mining machine was sumping or shearing and loading at the face. Respirable dust was measured using instantaneous light-scattering devices developed for the Bureau by the Stanford Research Institute (SRI). The instruments were calibrated by parallel gravimetric sampling with a laboratory dust box. Results were reproducible and are considered to be significant from a relative viewpoint. The respirable dust concentration was measured in the return behind the brattice approximately 20 feet from the face. The cyclone classifier was placed 2 feet below the roof and midway between the brattice and the rib; this position was constant in all of the tests. Dust concentrations were recorded continuously before, during, and after each stamping or shearing and loading operation. Figure 1 gives a typical result obtained with a shear cut made between 5 and 32 seconds on the time scale. The total mass of respirable dust in the return was calculated by determining the area under the curve and multiplying it by the air quantity in the return. (The intake dust level was <0.1 mg/m³ and was negligible.) The percent dust reduction, R, of a spray system relative to a dry system is given by R = (1-W/D) x 100, where W and D represent the total respirable dust measured in the return during wet and dry cuts, respectively.

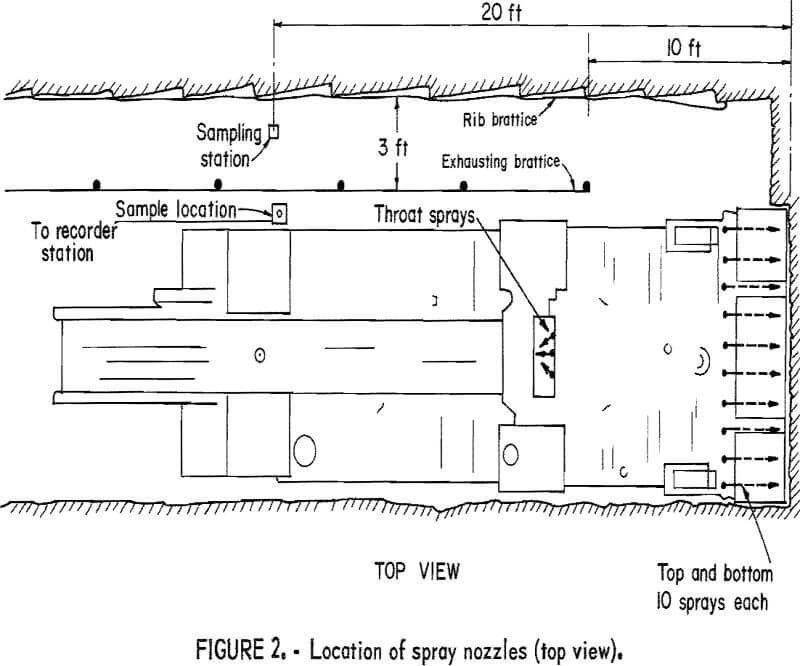

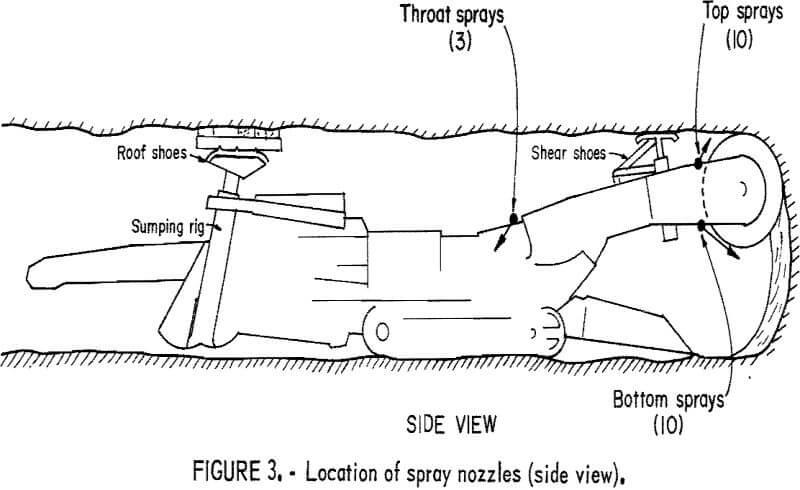

Figures 2 and 3 show the location of water spray nozzles on the LN 456 used in this program. Ten nozzles were located on the top of the boom, and the water sprays were directed toward the face. Ten nozzles were located underneath the boom, and the sprays were also directed toward the face. Finally, three nozzles were located in the throat of the machine and directed backward onto the conveyor.

All nozzles were maintained unclogged, and coverage visually was good. Valves were installed in the water lines so that any or all sets of nozzles could be used. Hollow-cone Spray Systems BD-3 nozzles were used at all locations. The BD-3 nozzle gives a spray angle of about 75° for the pressures used here (60 to 200 lb/in² gage). Water flows were measured with glycerine-filled pressure gages inserted at the nozzle location prior to each set of tests. Fluctuations in water flow and pressure were negligible.

Air velocity behind the exhaust brattice was measured with a spinning, vane anemometer prior to each sumping operation and adjusted to give 4,000±100 ft³/min to the face area.

In a typical test series, a set of spray nozzles were selected and a 12-inch-deep box sump at the top of the seam was made by the machine operator, with the machine being stopped at the end of the sump. When the dust level had reached background level after the sump, the automated downshearing and loading operation was done. Three additional sets of sumping and shearing and loading cuts were then made on the box. The face was then trimmed, and a new test series with a dry cut or set of nozzles was made. Sump velocity was 5 ft/min. Shear velocity was 3.3 ft/min.

Results

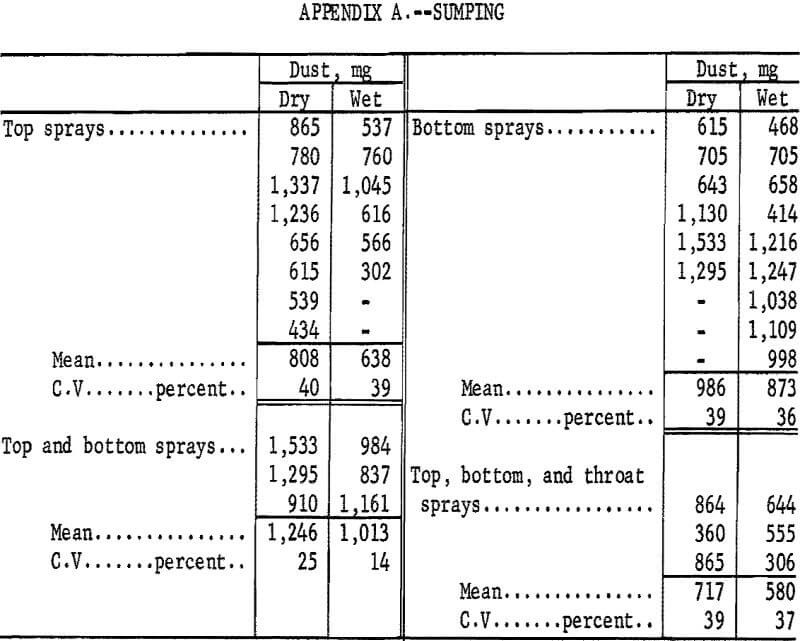

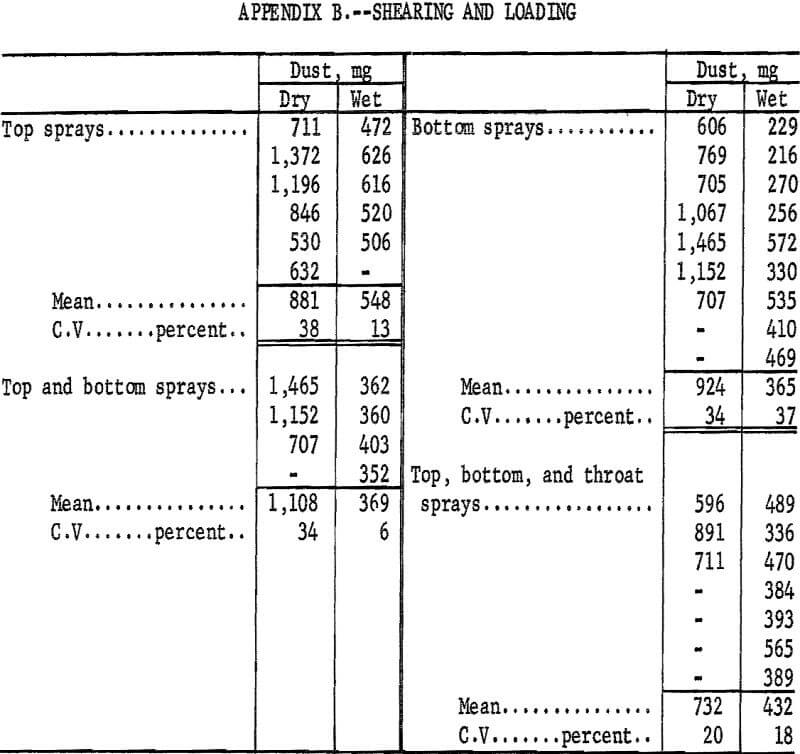

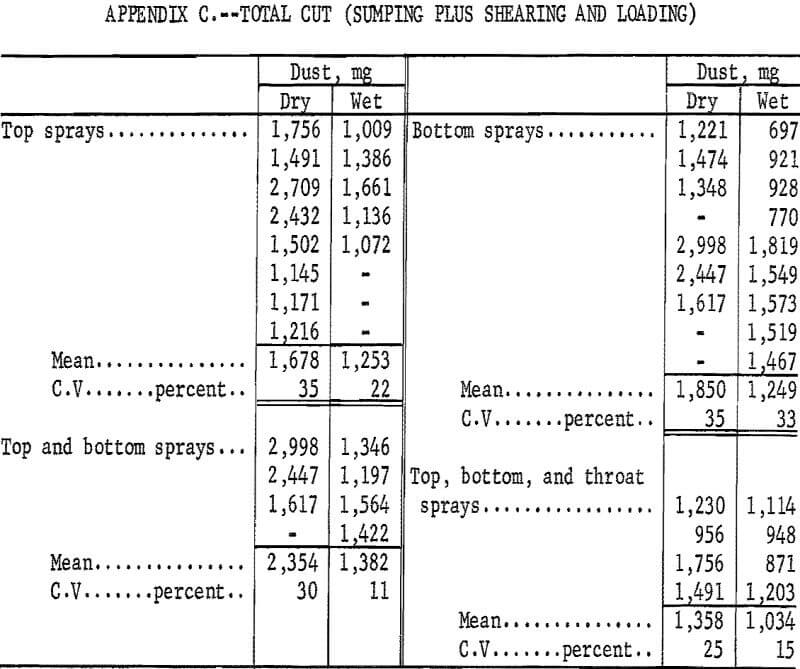

Raw data for sumping and shearing and loading are given in appendixes A and B. Individual sumping and shearing and loading data were added to give the total cut at the face (appendix C). Dry and wet cuts are included. The average amount of respirable dust formed was 940 mg in the dry sumping cut and 910 mg in the shearing and loading cut. Since about 1.5 times more coal was produced in the shearing and loading cut than in the sumping cut, the sumping cut was approximately 1.5 times more dusty than the shearing and loading cut for the same amount of coal produced; that is, the sumping cut caused 60 percent of the total amount of respirable dust during the box cut at the face and the shearing and loading cut contributed the other 40 percent. Dry sumping formed ~1,200 mg/ton of respirable dust, and dry shearing and loading thus formed ~800 mg/ton. Previously, about 250 and 40 mg/ton were formed, respectively, owing to high moisture in the coal seam.

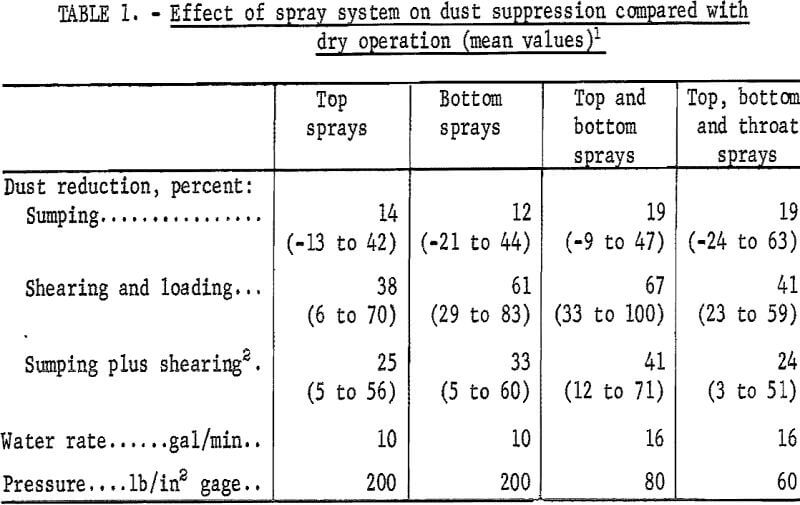

The reductions in respirable dust achieved with various spray systems compared with dry operation are summarized in table 1. Dust reductions obtained by a simple comparison of mean dust values are given along with the reductions obtained at a 90-percent confidence level. For example, for top sprays in shearing and loading, the simple comparison of mean values gives a 38-percent reduction, while the spread in the data indicates that, at a 90-percent confidence level, the reduction is at least 6 percent and can be as high as 70 percent. Using the simple comparison of mean values, the present results indicated that—

- For sumping, the top and bottom spray systems were equally effective and reduced the dust -13 percent.

- For shearing and loading, the bottom spray system reduced dust 60 percent and was 50 percent more effective than top sprays.

- For the total sumping and shearing and loading operation, bottom sprays are more effective than top sprays (33 percent reduction versus 25 percent).

- With combined top and bottom sprays, the total reduction was 41 percent . This increase in reduction compared with reduction using top or bottom sprays probably is due to the increased water (16 versus 10 gal/min) and the increased coverage.

- Inclusion of throat sprays decreased the reduction achieved during shearing and resulted in a total reduction of only 24 percent because the sprays withdrew some of the water from top and bottom sprays where it was more effective.

In the present work the top sprays were about as effective for sumping as was observed previously (14- versus 20 percent reduction), but the bottom sprays were much less effective (only 12- versus the previous 53-percent reduction). This disparity may be due to the shallower sump used here (12 versus the previous 18 inches), the different orientations of the bottom spray systems (forward versus the previous downward orientation), or the different moistures in the coal (2 versus the previous 5 percent). The different orientation of the bottom spray systems leads to a significantly different type of spray coverage and also to a different degree of air entrainment.

The manually controlled sumping in the present work led to a greater variability in dust levels than in the previous work; the average C.V. was 31 percent versus the previous 21 percent. The automated shearing and loading operation was slightly more reproducible than before; the average C.V. was 32 percent versus the previous 45 percent. The average C.V. for tests conducted on the same day was only 17 percent, comparable to the 20 percent observed previously.

While the automated operation of the modified 456 machine thus gives a slight improvement in reproducibility, a manually operated machine appears to give a reasonably satisfactory test technique. The increase in C.V. when comparing day-to-day results is probably due to using different SRI samplers on different days and to change in miner operators.

Future work would be oriented toward clarifying the importance of sump depth, the role of air entrainment, the effects of line pressure and water flow rate, and the importance of forward versus downward sprays located under the boom.

Conclusions

- About three-fifths of the respirable dust produced at the face is formed during the sumping operation, and the rest is formed during shearing and loading.

- During sumping, top and bottom sprays were equally effective in dust suppression and reduced dust -13 percent. However, in shearing and loading, bottom sprays reduced dust 61 percent and were about 50 percent more effective than top sprays. The combination of top and bottom sprays was more effective than the separate systems, but water consumption increased 60 percent.