Lime is transported in large volumes by the three common surface modes, i.e., barge, railroad, and truck.

Barge Transportation

Barges used in lime transportation have a capacity up to 1,500 tons and 1,400 ton loadings are very typical. The hulls of the barges are double skinned and constructed with water-tight sections. This type of barge design protects the lime in the cargo compartment in the event the outer steel surface of the hull is punctured or ripped open. The water-tight sectional design virtually insures that the barge will not sink if the outer hull surface is ruptured.

The lime is protected by barge covers. These barge covers may be rolled aside or lifted off during loading or unloading. Once the covers are closed they are weather-tight and protect the lime from rain, wind, and other adverse weather conditions.

Loading and unloading can only be done when there is no rain. Loading and unloading systems must also effectively control dust emmissions. Loading is accomplished by spouts and chutes that lower into the barge, vacuum (negative pressure) air lines literally pulls the dust from given points in the loading system. The air in the vacuum lines is cleaned and filtered through bag houses. A 1,400 ton barge can be loaded in three or more hours. River terminals receiving lime in barge load quantities must have fast and effective unloading systems. While some vacuum and bucket elevator systems are used, overhead and whirlie cranes equipped with clamshell buckets are most common. The clamshells have capacities varying from two ton to fifteen tons. A 1,400 ton barge can be unloaded in as little as four hours. The clamshells drop the lime into specially designed hoppers. From these hoppers, the lime is moved to water-tight steel or concrete silos by means of conveyor belts, bucket elevators, and screw conveyors. Because of their location, usually on river sites, many power plants receive and unload both lime and coal from barges. A special hopper used in barge unloading will be discussed in a later section of this paper.

Railroad Transportation

Lime is transported by railroad in covered hopper cars or special pneumatic cars. The capacity of the cars vary from 50 to 100 tons but 100 ton cars are becoming more common. Loading is by expandable chutes or spouts that can be lowered to the load hatches of the car.

Double skin spouts in which the outside chamber has a vacuum dust pick up are becoming more common if not mandatory in many cases.

Unloading the special pneumatic cars is accomplished by pressurizing the car and blowing the lime to the silo as in the case of a pneumatic truck. Covered hopper cars may be unloaded by dropping the lime into an undertrack hopper and transferring the lime to silos by means of conveyor belts and bucket elevators or transferring pneumatically from the undertrack hopper or directly from the railroad car. Unloading time for a railroad car depends upon the number of pockets that can be unloaded at one time. A car will normally have three to five pockets. If all the pockets can be opened at once, then the car could be unloaded in 15 to 30 minutes. If only one or two pockets can be opened at one time and the car must then be shifted, then unloading time per car can be expected to exceed one hour. Steel plants commonly receive lime by rail.

Truck

Dump Truck

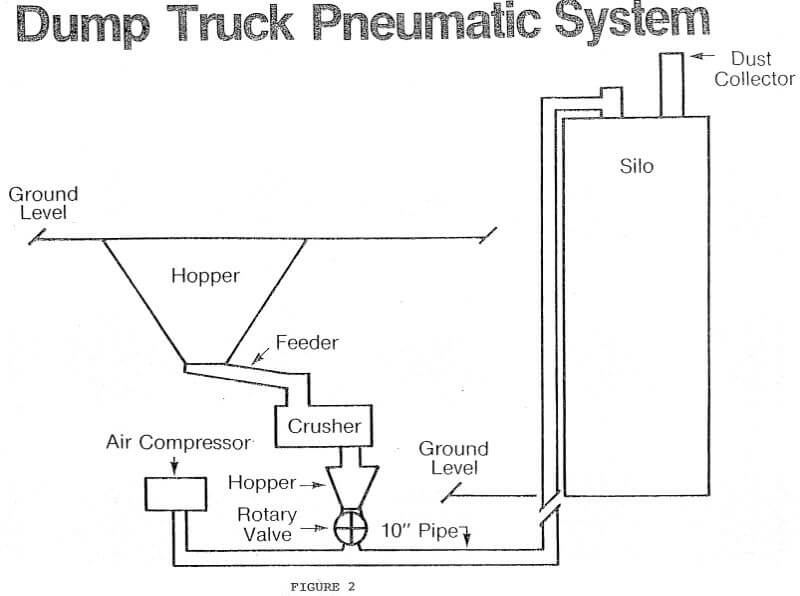

Dump trucks normally transport 20-25 tons of lime. Loading is also done by a double skin spout in which the outside chamber picks up dust by means of negative pressure. After loading, the dump truck bed must be covered by a tight fitting tarpaulin. Dump trucks dump into underground hoppers in approximately five minutes. Lime is transferred to silos by conveyor belt or pneumatically. A pneumatic transfer system is shown in Figure 2. In this system the lime passes through a crusher to insure a minimum top size and then by means of a rotary valve is transferred to a positive pressure pneumatic system and transferred to silos. This system is used by some power plants that we serve in the Pittsburgh area.

Pneumatic Truck

Pneumatic trucks can transport 20-25 tons of lime. These trucks are normally used by installations with limited storage capacity. The receiving systems are relatively less costly than dump truck or barge unloading. Loading is again done by the dust controlled double skinned spout. The pneumatic truck is unloaded by a pressure differential system. Air for the unloading is supplied by means of a blower. The truck may have its own blower or use a permanent plant blower. The tank unloading lime is pressurized at about 12 to 14 psi, the pressure on the product forces the product down into the tank discharge pipe where the lower pressure moves the product to storage. Lime sized to -¾” is usually the largest size unloaded pneumatically. The unloading lines are normally 4″ in diameter. These pneumatic lines should be vertical or horizontal. Inclined lines do not permit pneumatic conveyance as well as vertical or horizontal lines. Horizontal runs cut the efficiency and should be limited to minimum distances. All turns should be large radius turns. ( A rule of thumb: Radius of turn should be one foot for each one inch diameter of the conveying line). Unloading time for a pneumatic truck is normally one hour.

Related: 8 Best Folding Hand Trucks