Regrind Ball Mill

F = 210 micrometers.

P = 45 micrometers.

Wi = 14.0

W = 10 x 14.0/√45 – 10 x 14.0/√210 = 11.21 kwh/s. ton

Efficiency Factors:

EF1 does not apply.

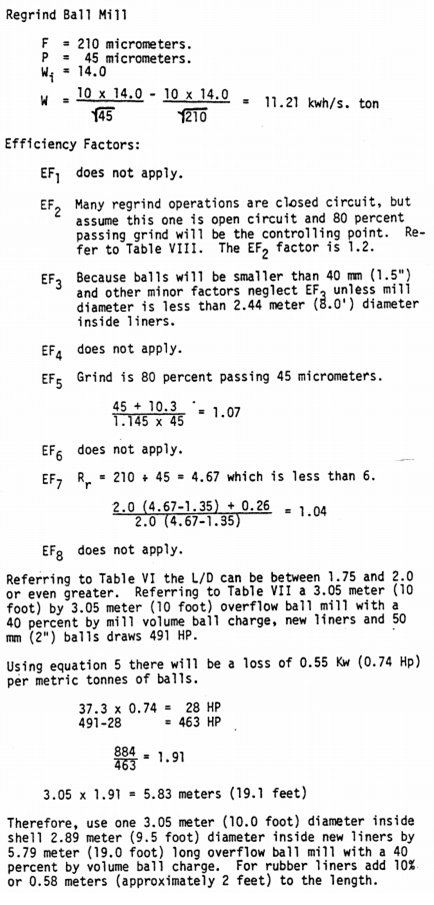

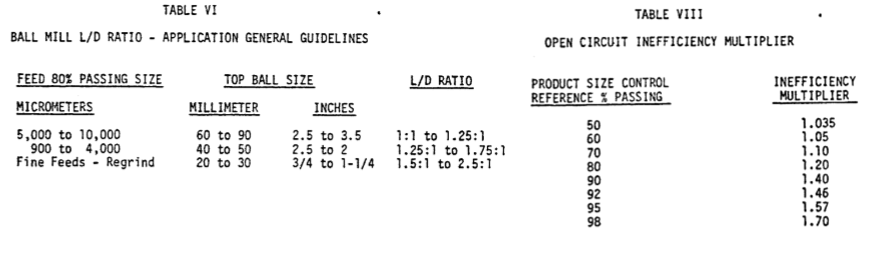

EF2 Many regrind operations are closed circuit, but assume this one is open circuit and 80 percent passing grind will be the controlling point. Refer to Table VIII. The EF2 factor is 1.2.

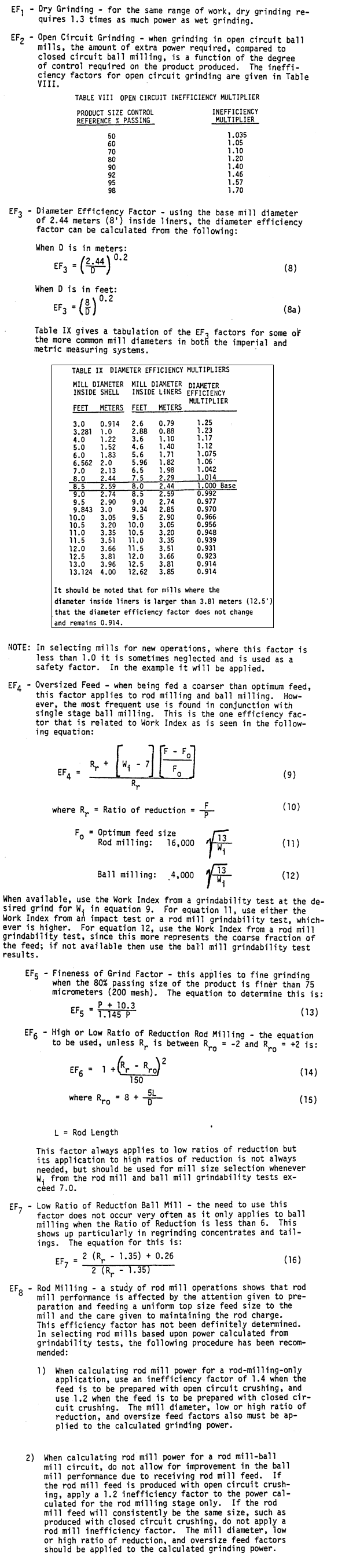

EF3 Because balls will be smaller than 40 mm (1.5″) and other minor factors neglect EF3 unless mill diameter is less than 2.44 meter (8.0′) diameter inside liners.

EF4 does not apply.

EF5 Grind is 80 percent passing 45 micrometers.

45 + 10.3/1.145 x 45 = 1.07

EF6 does not apply.

EF7 Rr = 210 ÷ 45 = 4.67 which is less than 6.

2.0 (4.67 – 1.35) + 0.26/2.0 (4.67 – 1.35) = 1.04

EF8 does not apply.

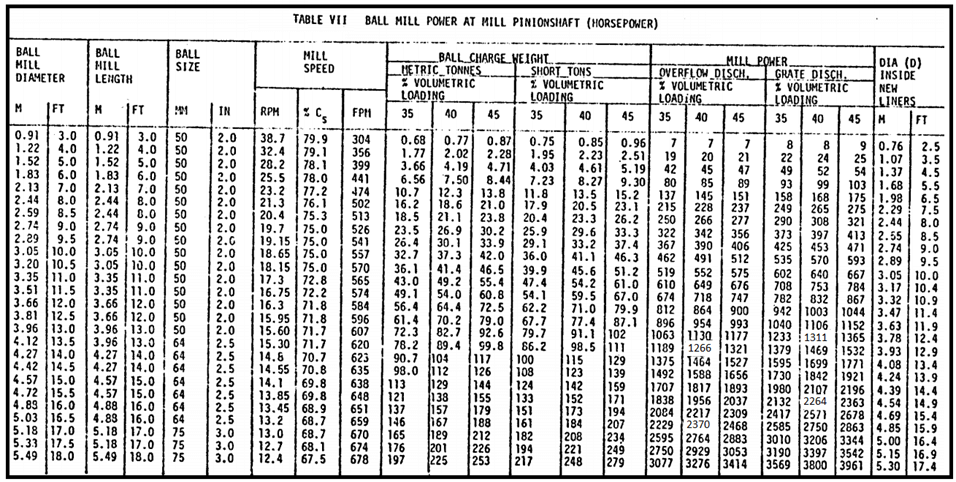

Referring to Table VI the L/D can be between 1.75 and 2.0 or even greater. Referring to Table VII a 3.05 meter (10 foot) by 3.05 meter (10 foot) overflow ball mill with a 40 percent by mill volume ball charge, new liners and 50 mm (2″) balls draws 491 HP.

Using equation 5 there will be a loss of 0.55 Kw (0.74 Hp) per metric tonnes of balls.

37.3 x 0.74 = 28 HP

491-28 = 463 HP

884/463 = 1.91

3.05 x 1.91 – 5.83 meters (19.1 feet)

Therefore, use one 3.05 meter (10.0 foot) diameter inside shell 2.89 meter (9.5 foot) diameter inside new liners by 5.79 meter (19.0 foot) long overflow ball mill with a 40 percent by volume ball charge. For rubber liners add 10% or 0.58 meters (approximately 2 feet) to the length.