If the ore be poor, it ought to be concentrated, the vein stuff being got rid of as much as possible. If mixed with iron or copper pyrites, it ought to be calcined or else treated with acids. One method is, as in Cornwall, to mix the ore with one-fifth of its weight of anthracite coal or charcoal and to expose it in a crucible to a great heat for about twenty minutes. The contents are then poured out into an iron mould, and the slag carefully examined for buttons.

If the ore be poor, it ought to be concentrated, the vein stuff being got rid of as much as possible. If mixed with iron or copper pyrites, it ought to be calcined or else treated with acids. One method is, as in Cornwall, to mix the ore with one-fifth of its weight of anthracite coal or charcoal and to expose it in a crucible to a great heat for about twenty minutes. The contents are then poured out into an iron mould, and the slag carefully examined for buttons.

Another method is to mix 100 grains of the ore with six times its weight of cyanide of potassium, and expose the mixture to the heat of a good fire for twenty minutes. The contents are allowed to cool, and afterwards broken to remove the slag. The buttons are then weighed.

Assaying Antimony

To determine the amount of antimony in an ore containing sulphide of antimony and more or less vein- stuff:—

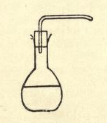

Place about 2,000 or more grains of broken-up ore in a crucible, the bottom of which is perforated, and the hole in which is partially closed by a small piece of charcoal. Now fix the bottom of this crucible into the mouth of another crucible, so as to be about halfway down its depth. Then lute the lid and also the joint between the two crucibles with fireclay and sand. By placing the lower crucible under the furnace bars and the upper one above, the heat of the furnace will cause the sulphide of antimony, which fuses at a red heat, to collect in the lower crucible, while the quartz and other matter will remain in the upper one. The operation should take about an hour and a half. When pure, sulphide of antimony contains a little more than 70 per cent, of metal.