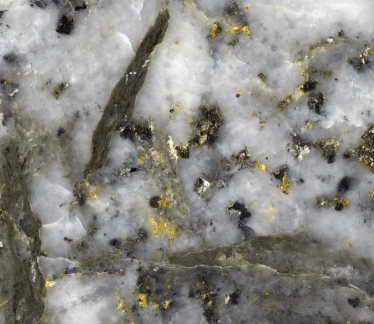

As run for student class-work the mill contains a feeder, stamps, plate, and vanner. Results in the past indicate that the work of these machines is just as efficient as that of a regular mill handling the same class of ore. It has been the custom to obtain ore principally from Nova Scotia, mainly because it is the nearest source of supply, and also because there is a considerable saving in freight-cost as compared with other districts. The gold in Nova Scotia ores is notoriously coarse, and for this reason it is almost impossible to obtain satisfactory results by sampling and fire-assay, unless an extremely large lot of ore is crushed and all of the contained gold pellets are saved. A very interesting and most extraordinary example of this fact has been presented by a recent run in the Technology stamp-mill.

Since the capacity of the mill is about 60 kg. per hr., and since in about 5-hr. run the students in any one section have an opportunity to make the necessary study of machines, it usually happens that several runs are made from one lot of ore.

When the shipment is received it is first dried and weighed, put through the Blake breaker, set at 1 or 1.5 in., and the crushed product is piled in a cone on the sampling-floor. When the crushing is completed the ore is usually stored away in barrels for future use; it is aimed to have each barrel of the same quality as the others. The barrels are filled up by a man shoveling around the circumference of the cone, the first shovelful going to barrel No. 1, the second to No. 2, and so on. This method of sampling is not claimed to be absolutely perfect, but it is entirely satisfactory for the purpose in view. When the time arrives for a stamp-mill run two barrels are taken at haphazard from the lot and used, the ore being fed in 10-kg. lots, which are weighed out carefully by the students, and fed as needed into the hopper of the feeder. As each student weighs out a lot he takes a small grab-sample from the residue and places it one side into the sample-hod. When the end of the run is in sight, this sample-hod, which is usually nearly full of the sample, is carried to the crushing- and sampling-department, where the ore is first weighed, and then crushed in rolls until it passes a screen of the same size of aperture as that used in the stamp-mill. Any pellets of gold in the ore are flattened out by the rolls, and are readily picked out from the oversize of the screen. The undersize of the screen is further sampled down to an assay-sample, put through a 100-mesh screen, the pellets, if any, being saved, and the pulp assayed. The remainder of the material passing through the roll-screen is weighed out in 10 kg. lots, and fed with the coarse ore into the stamp-mill.

The sampling and assaying of a Nova Scotia gold-ore by the above method is entirely inaccurate, and the only justification for the procedure is that the results when compared with the true gold-content of the ore, as shown by the recovery of gold from the amalgams, and from the assays and weights of the products, will serve as a warning to the student for his future practice.

Usually the fire-assay runs lower than the mill-assay, and this seems perfectly natural when one considers that there are comparatively few nuggets of gold in the two barrels of ore, and the chances are that the students will miss them in the sampling. Occasionally, however, chance favors the sample, and it will contain more than the proper proportion of nuggets, and in that case the fire-assay rises higher than the mill-assay.

To present specific data: a load of ore received more than a year ago from Tangier, N. S., weighed 2,256 kg., net. Upto the present time there have been three separate runs on this ore, as follows:

Looking over the tabulated data the first two runs are not greatly different from what is usually obtained. The mill-assays agree fairly closely, 0.413 and 0.379 oz. respectively. The first run had more than its proportion of pellets in the sample, and therefore the fire-assay shows higher. In the second run the reverse is true. It is in the third run, however, that is found such a remarkable example of the workings of chance. The following tree shows the procedure in the third run:

During the sampling it was noticed that only two pellets appeared on the 30-mesh screen, but these were both of good size. No pellets were found between 30- and 100-mesh. The pulp through 100-mesh assayed 0.08 oz. of gold per ton. After the run the amalgams were cleaned, retorted, and the fine gold determined, also all the concentrates and tailings were dried, weighed and assayed, and the gold-contents figured. In this way the total gold in the original lot of 372 kg., including also the weight of gold in the two pellets, was obtained, and from these data was calculated the total gold there would be in a ton of ore, or, as it is called, a mill-assay. It is clear that the pellets should be included in this total, because if it had not been for the sampling they would have gone into the stampmill and would have appeared in the clean-up of the mortar.

The weight of fine gold in the two pellets was 8.0446 g., this being obtained from the 18-kg. sample. The amount of gold in the amalgams and in the products was 1.9614 g., which represents the gold in the 354 kg. that was fed directly to the stamps, and also the gold in the 18 kg. of undersize that went to the stamps. Computing this as ounces per ton, the mill-assay given below is obtained. Similarly, the fire-assay in ounces per ton based on sample weighing 18 kg., pellets weighing 8.0446 g., and pulp assaying 0.08 oz. per ton, is obtained.

These two pellets of the third run are also accountable for the great drop in the saving by amalgamation to nearly 20 per cent, below the first two runs, and for the increase in loss from 2.95 and 1.69 respectively up to 19.59 per cent. What actually happened was that the ore fed to the stamp-mill in the third run really assayed only 0.20 oz. of gold per ton, whereas, in the first two runs it assayed twice that amount. If the two pellets had gone into the stamp-mill they would have appeared in the clean-up of the mortar, and the following results would have been obtained—not greatly different, as far as extractions and losses go, from the first two runs :

Manifestly, the only way to sample an ore of this kind accurately is to crush the whole of it down to a comparatively fine size; but if this were done, then the stamp-mill run would have to be sacrificed. It seems proper, therefore, to sacrifice the accuracy in sampling in order to have a satisfactory stamp-mill run.

That the fire-assay is unreliable is well known to Nova Scotia miners, because any one in that Province unless he is a “tenderfoot ” will never place much confidence in the value of a mine on the testimony of fire-assays alone, but prefers always to have the results of mill-runs on several lots of ore.