In the anthracite fields of Pennsylvania, mine fires occur with more or less regularity and their existence is an ever-present hazard in coal mining. In all probability 90 per cent, of the mine fires can be ascribed directly or indirectly to the ordinary miner’s open lamp. Other causes may be smoking, electrical installations, gas explosions, gas feeders, and the communication of fire to the outcrops from ash dumps, culm banks, timber and brush fires.

Fires in pump rooms, engine rooms, and barns have been largely eliminated as a result of the Act of Assembly, approved June 15, 1911, which provides that all inside buildings, including engine rooms, pump rooms, barns, etc., shall be constructed of incombustible materials. Smoking of pipes, cigars, and cigarettes should be prohibited in the mines and too much care cannot be exercised in preventing fires by enforcing all rules designed for that purpose. Mine fires that involve underground fighting are invariably dangerous, and all fires, irrespective of the method pursued in extinguishing them, involve property loss and expense.

Each fire generally presents a more or less original problem, dependent on the particular conditions. Generally mine fires may be divided into two classes: Those occurring in inaccessible workings and those occurring in accessible workings. The methods pursued in extinguishing or controlling mine fires are as follows: (1) direct attack, (2) smothering by sealing, (3) flushing with silt or other solids, (4) flooding with water, (5) cutting off, (6) surrounding with incombustible materials, (7) digging out by stripping from the surface.

Most fires are extinguished in their incipiency by direct attack and failure to extinguish by this method is due to late discovery, lack of water, and facilities for fighting, or improper procedure in the initial attack. Should the method first pursued be unsuccessful, careful consideration should be given in determining next the method to be adopted; then the work should be carried on as rapidly as possible and under the supervision of the most competent persons. Materials and supplies should be furnished without delay and in sufficient quantities for the work to be accomplished.

Following the discovery of fire, the foreman or superintendent should organize the men available at the location of the fire and, if necessary, send for others experienced in fire fighting. The regulation of the ventilation should be promptly attended to by the foreman or his qualified assistants. The regulation of the air supply to the fire area is of prime importance as too much air will generally increase the extent of fire and too little will increase the liability of explosion.

As most fires occur in accessible locations, they are naturally fought direct in their incipiency and in most cases are so extinguished. But the extinguishing of fires by direct attack has not been confined to small fires or fires in their incipiency as fires have been extinguished by this method after months of work. However, the direct fighting of fires over long periods of time is falling into disfavor and the safer and more efficient method of sealing where practicable is generally practiced.

The speed of travel of a mine fire is dependent on the conditions in the immediate vicinity of the fire. With dry timber and a strong ventilating current, a fire will make rapid progress; while in coal, the progress is extremely slow, except where there is communication with an overlying vein through caves and broken ground.

The most practical, and probably the most efficient, means of direct fighting is with water directed in hose streams of good pressure and capacity, which can only be secured by providing pipe lines of adequate capacity. A system of water pipes, standardized as far as possible, should be maintained for immediate use in mines liable to fires, and maps giving the location of these lines should be provided periodically to the colliery officials. Pipe, hose, connections, valves, wrenches, nozzles, etc. should be maintained at definite points of convenience.

In the sealing of fires, the conditions favorable to this method are: limited area of workings to be sealed and minimum number of seals required. The unfavorable conditions are extensive workings and caved workings with liability of connections through cracks and crevices to overlying veins or the surface. The principal danger is the liability of explosion, which prompts the question as to whether the intake or return stoppings should be erected first. The question has always been a matter of dispute; in 1912, the editors of Coal Age invited discussion which resulted in thirty-three opinions being given. Of these sixteen would close the intake first, ten would close the return, six would close the intake and the return simultaneously, and one would close either intake or return first.

There have been many failures to extinguish fires by flooding the areas with water because anticlines and pockets in the workings prevented the water submerging the fire, owing to the compression of the mine air. To illustrate the sealing method of extinguishing mine fires the procedure followed in extinguishing two fires by this method is given.

SOUTH WILKES-BARRE NO. 5 COLLIERY FIRE

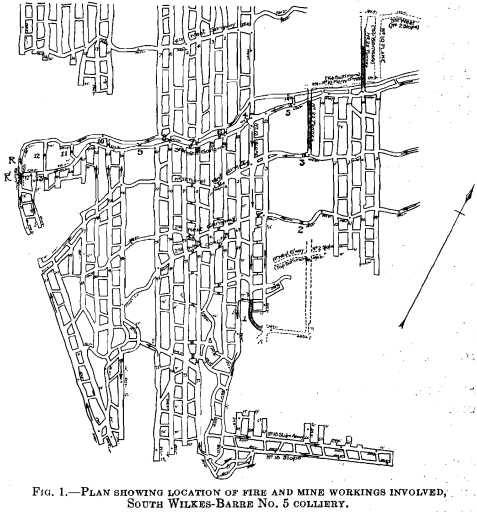

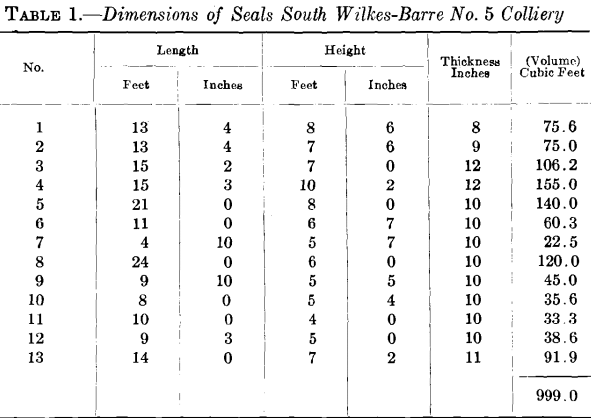

The fire in the South Wilkes-Barre No. 5 colliery originated on No. 13 slope close to the 3d west gangway at point X, Fig. 1. A workman had repaired a roof pulley at this place during the night of Feb. 20, 1919, and it is presumed that the timber was ignited by his lamp about 10 o’clock. It was discovered at 4.45 the next morning by a fire boss, who found several sets of timber on fire. He immediately went to the surface and reported to the inside foreman, while the other fire bosses proceeded to fight the fire with two hose streams of water. When the foreman and superintendent arrived, two sets of timber had burned through and some top rock had fallen. The fighting of the fire with hose streams was continued at this location until 10 o’clock, when it was found that the fire had traveled up the slope to the No. 23 tunnel west gangway, as there was considerable timber while falls of roof made the work of fighting slow. The men were then moved to the No. 23 tunnel west gangway and continued fighting direct with two hose streams until 10 o’clock that night, when it was found that the fire had passed the 2d west gangway. The men were then moved to this gangway and the fire fought from there until the next noon, when it was decided to seal the fire area.

During the 31 hours of direct fighting the ventilation was regulated to give only sufficient air in the immediate vicinity of the fire to avoid accumulation of smoke and gases, which would seriously interfere with the work; also the water supply was augmented by utilizing a compressed- air pipe line from the surface to the No. 23 tunnel east gangway.

The ventilation of these workings, previous to the starting of this fire, is shown by arrows. It will be observed that the intake passed up No. 13 slope and slope airway and returned to the face of the 3d west gangway where it passed through a regulator R’ located in a rock plane to the Top Baltimore vein. The quantity of air passing near the top of No. 13 slope to No. 18 slope workings was approximately 14,000 cu. ft. per min. and the quantity returning through the regulator R’ to the Top Baltimore was approximately 20,000 cu. ft. There was a small split of air passing in the 3d west airway and through the regulator R’, where it joined the split from the fire area.

The hoisting shaft at this colliery has a depth of 1040 ft. and the distance from the foot of shaft to the origin of the fire is 6500 ft. The origin of the fire is 1300 ft. below the surface.

To seal the fire, all materials were transported on the 3d west gangway from No. 2 slope to the foot of No. 10 plane and to No. 25 tunnel and carried by men from these points to the locations of the seals. The seals were located at points 2, 3, 4, 5 and 6 and were constructed by first securely setting between roof and bottom 6-in. props spaced about 4 ft.

To these props brattice boards were nailed and the stoppings made reasonably tight by fitting small pieces of brattice boards into the irregularities of the ribs and roof and nailing to the brattice boards. The cracks in the brattice were then covered with battons having the top edge beveled to permit sealing, which was done by applying lime mortar to the edges of the battons and along the roof and ribs.

Seal 2, on the 2d west gangway, was built with a 5 by 5-ft. opening but seals 3, 4, 5, and 6 were built continuous and without openings. Seals 2, 3, and 5 were completed first and immediately upon completion of seals 4 and 6 a door was put over the 5 by 5 ft. opening in seal 2. This door was made of two thicknesses of brattice boards with canvas between and a sealing strip at bottom. This door was put up at 3.20 A. M., Feb. 23, and all men immediately withdrawn. The fire area was now closed on the intake side as headings 7 to 12 on the 3d west gangway contained old walls. Where No. 13 slope passes through the rock from Bottom Baltimore to Top Baltimore, at location of seal 1, there was an extra main door, which was closed at 7 A. M. Feb. 24, covered with canvas, and banked with dirt along the bottom. A concrete seal 8 in. thick was built against the door and completed the same day. On the following day concrete seals 2, 3, and 5 were built against the brattice stoppings put in on the 22d, and on the 26th concrete seals 4 and 6 were built against the brattice stoppings previously constructed. On the 27th, the work of building concrete seals 7 to 12 against the old walls was begun. After the completion of the seals, the 3d west gangway was closed between chambers 70 and 71 at 4 p. M. March 1, after some difficulty because of escaping gases.

All of the concrete seals, with the exception of No. 13, were built against stoppings previously constructed, by first standing wooden mine rails about 2 ft. apart and approximately 12 in. from the original stopping. Boards were then put on the inside of the vertical wooden mine rails and concrete placed between these and the original stoppings. At the time of putting in these concrete seals, pipes were put in seals 1, 2, 3, and 4 for the purpose of taking samples of the enclosed air for analysis.

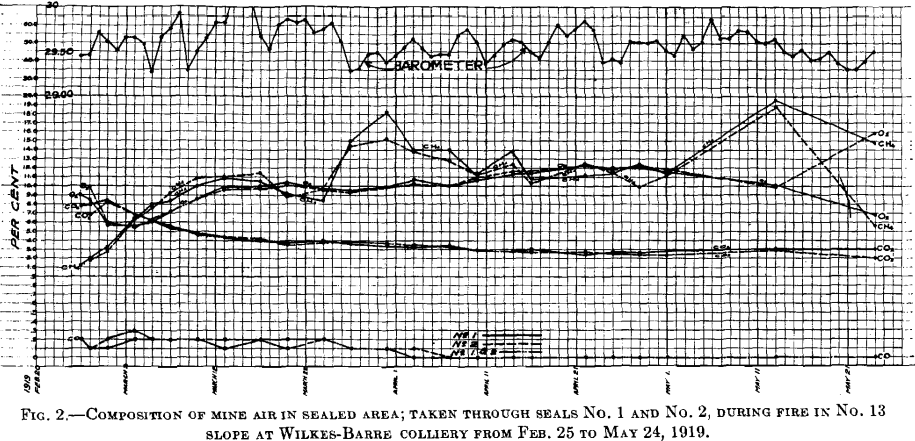

The analysis of mine-air samples from seals 1 and 2 are shown graphically in Fig. 2. The dimensions of the seals are given in Table 1. The amount of concrete placed in the thirteen seals was 37 cu. yd.

The sealed area covers 32.8 acres and the volume of the mine openings amounts to approximately 4,350,000 cu. ft. An average section of the vein is 7.75 ft., divided as follows: Coal 2.15 ft., rock 0.70 ft., coal 4.90 ft. A maximum of 79 and an average of 17 men were employed in fighting the fire and building the seals, a total of 4363 man-hours, at a cost of $2555.15. The labor expended from March 3 to 29 was used in going over the seals and pointing all cracks and leaks.

On May 29, the seals were opened by first removing the upper portion of concrete of seal 1, after which an opening 10½-in. high and 27 in. long and about 2 ft. below the roof was made through the door, which formed the backing of this concrete, seal. The gases emitted from this opening filled the head of the slope in a very short time. An opening 7 ft. square was then made in seal 13, which rapidly relieved the gas pressure at this point; and finally the 5 by 5-ft. trap door in seal 2 was removed at 3.10 P. M. of the same day. The men employed in this work were then withdrawn. At 7 o’clock the next morning, the superintendent, foreman and several fire bosses examined the fire area and found that the fire had been extinguished; they also found that the fire had extended to the second heading above the 2d west gangway, a distance of 520 ft. from its origin, where it had died out soon after the closing of the intake seals.

NOTTINGHAM NO. 15 COLLIERY FIRE

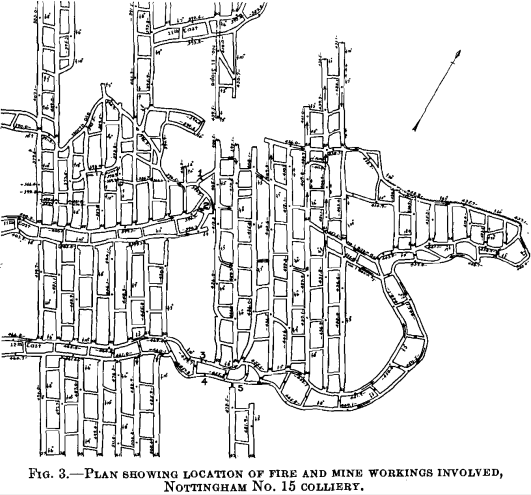

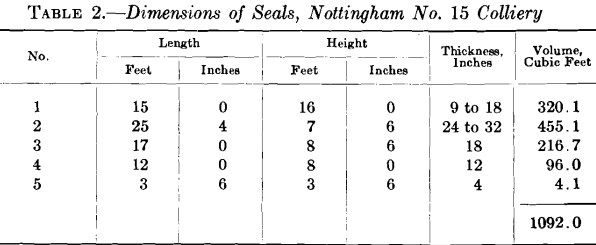

This fire originated opposite chamber 61 on No. 1 basin gangway, 12th east, No. 3 slope at point X, Fig. 3. A laborer working in this vicinity at 2.45 P. M., May 1, 1919, went to the miner’s box and filled his lamp with oil; he then brushed the lamp wick against the box to spread the cotton and knock off the incrustation, and left immediately so as to catch the man trip up the slope. At 6.20 P. M., a fire boss found the box ablaze, also the platform on which it stood, and some old ties near by. He went for help and on his return found that the fire had reached the brattice and the timber in the chamber. A fall of top coal had occurred during his absence and there was evidence of fire under it.

While the fire was fought with water carried in powder kegs from the ditch on the 13th east gangway, hose was being secured and word sent to the assistant foreman. About 9 o’clock hose had been obtained and a stream was played upon the fire until 10 A. M., May 4, when two additional hose streams were secured by utilizing a 3-in. high-pressure air pipe on the 11th east gangway and extending with 2½-in. pipe and hose down chamber 56 to the 12th east gangway, thence in the gangway to the fire. During the fighting of the fire, which had communicated to the fall of top coal, 41 cars of coal were loaded and removed by 8 A. M., May 3, but in so doing many of the men were overcome by the gases of combustion. At this time the organization fighting the fire was disrupted by trouble in another section of the mine, so the fire gained considerable headway. Fighting continued, however, until 2 P. M., May 4, when it was decided to seal the fire area. During the 65 hr. of direct fighting, the ventilation was regulated to give sufficient air in the immediate vicinity of the fire to prevent serious accumulations of smoke and gases.

The ventilation of these workings previous to the fire is shown, in Fig. 3, by arrows. It will be observed that the intake entered from the 11th and 12th east gangways and returned on the 12th east airway. The quantity of air in the return was approximately 20,000 cu. ft. per min. The hoisting shaft has a depth of 365 ft. and the distance from the foot

of shaft to the fire was 12,100 ft. The depth from the surface to the origin of the fire is 950 ft. Materials used in the construction of the seals were transported on the 11th and 12th east gangways to within 100 ft. of the seal locations. The locations of the seals are indicated by numbers 1 to 5. They were constructed by setting two rows of wooden mine rails between the roof and bottom, spaced about 3 ft. apart, with from 14 to 26 in. between the props, depending on the thickness of seal to be built. To the inside of these props, sheathing boards were nailed and the space between filled with concrete.

The construction of seals 1 and 2 was started at 2.30 P. M., May 4, and seal 3 at 6.00 P. M., May 5. Seal 1 was built without an opening but seal 2 had a 4 by 4-ft. opening and seal 3 a 6 by 6-ft. opening. Seal 1 was completed at 2.45 P. M., May 6, and seals 2 and 3 were completed about the same time, except for closing the openings, which were closed with concrete during the next hour. The fire area was thus closed on the intake side and all men immediately withdrawn. Immediately after seal 3 was closed, the doors in the two headings outside of the seal were thrown open, thereby short-circuiting the air to the 12th east airway.

At 9.15 P. M., May 7, after an examination was made, with the use of oxygen helmets, the location for seal 4 was chosen and work started;

this seal was completed at 2.30 the next morning and all men were withdrawn. On May 10, a small opening, between chamber 48, from the 13th east gangway, and the 12th east airway was found and immediately closed with seal 5.

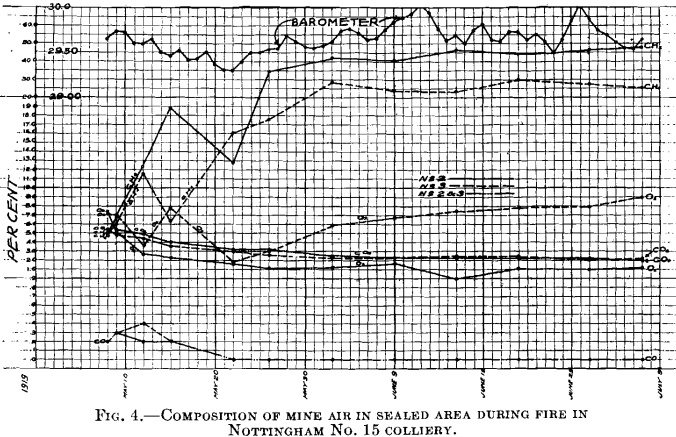

When seals 1 to 4 were built, pipes were put in so that samples of the enclosed air could be taken for analysis; also an 8-in. cast-iron pipe, with an elbow to form a trap, was placed in the bottom of seal 3 for the discharge of the water flowing in the ditch of this gangway. The hose line connected with the regular 12th east gangway water line was also arranged so that samples of the mine air could be taken through it from a point as near the fire as possible. The analyses of samples from seals 2 and 3 are shown graphically in Fig. 4.

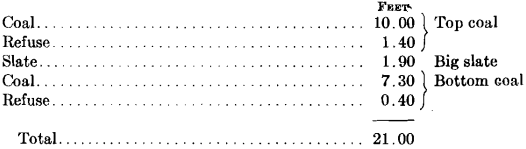

The dimensions of the seals are given in Table 2. The amount of concrete used in the construction of the five seals was 40.4 cu. yd. The sealed area covers 24.2 acres and the volume of the mine openings amounts to approximately 5,300,000 cu. ft. An average section of the vein is 21 ft. divided as follows:

A maximum of 110 and an average of 30 men were employed in fighting the fire and building the seals, with a total of 6846 man-hours, at a labor cost of $3979.60.

On July 12, the opening of the seals was begun at 6.45 P. M. by cutting out the concrete of seal 4, and an opening approximately 8 by 10 ft. was made in the inside sheathing of this seal by 11.15 o’clock thereby opening the return. A half hour later, work was started on seal 2 and the concrete in the 4 by 4-ft. opening was cut out by 4 o’clock the next morning. The doors in the headings outside of seal 3 were then closed. Preparatory to opening seal 2, the work of removing the concrete in the 6 by 6-ft. opening in seal 3, was begun; this was completed at 5.15 the following morning.

The men employed in this work were then withdrawn and the next day the superintendents and foremen made an examination of the fire area. They found that the fire had been extinguished and also that it had not extended beyond the first heading on the right of chamber 61, a distance of approximately 50 ft. from its origin.

This paper is presented in the hope that discussion of the methods of fire fighting will result and also that it may prompt the submission of other experiences in extinguishing or controlling particular mine fires in the anthracite field.

The writer acknowledges the assistance of J. D. Joseph, R. G. Carpenter, F. W. Seymour, and D. J. Thomas, colliery officials in collecting data relative to these two fires and also extends his thanks to M. S. Hachita for the preparation of tables and diagrams of air analyses.

DISCUSSION

The U. S. Bureau of Mines has always been deeply interested in mine-fire fighting; but its aid has been sought more in the western metal mines and in the bituminous coal districts than in the anthracite.

While the fires described have been admirably handled, there are a number of interesting features in the charts showing the rise and fall of the component gases behind the seals. Two or three things seem quite at variance with our experience with the gases produced by bituminous-mine fires that have been sealed. First, the oxygen content of a sealed area nearly always falls off rapidly after sealing and keeps falling, sometimes until it reaches zero, if the stoppings are tight. In both fires here described, if I understand the graphs correctly, the oxygen content decreased and then increased, which seems odd.

We have also found that the presence of carbon monoxide is a good indication of an active fire. Usually, the content has been higher at the start than shown by these graphs, in such fires as have been under my observation; then, as the flame has gone down, the carbon-monoxide content has dropped. However, the absence of carbon monoxide does not indicate that the fire is out, only that the flame is extinguished; the hot coals may remain ready to burst into flame when the sealed area is reopened. Therefore, it seems to me that in considering this matter, it would be helpful if Mr. Bunting would explain why the oxygen content apparently increased.

Another question is, what was the indication to the mine management that the fire was out? The time that had elasped in each case seems rather short. We have encountered fires (and I have no doubt you have in the anthracite district) when reopening sealed areas after long periods, even where it was thought the seals were tight. In the cases here discussed, was the coal on fire, or was the fire confined to timber? It has been our experience that when coal gets on fire, the hot coal will often be surrounded by ash and retain the heat for long periods of time— months and perhaps years—if there is a large body of fire. Also, was breathing apparatus used for preliminary exploration before restoring ventilation, to determine if the fire was extinguished?

No breathing apparatus was used in the South Wilkes-Barre fire. At the Nottingham fire, breathing apparatus was not used until it was necessary to seal the return. In both fires there was burning coal—more in the Nottingham fire where there was but little timber.

The analyses of the South Wilkes-Barre fire show, at seal 1, a decrease and then a slight increase in the oxygen content; the same variation applies generally, to seals 2, 3, and 4. At the Nottingham fire, the oxygen content diminished and then increased at seal 1; at seal 2, there was a decrease; at seal 3 there was a decrease and then an increase.

There was no positive indication that these fires were extinguished prior to opening the seals but our opinion was that the carbon monoxide content was the only indicator. When this was reduced to zero, we thought that the fire was out. In the case of the South Wilkes-Barre fire, the carbon monoxide disappeared in seals 1, 2, and 4, on April 7, and in seal 3, on April 10, so that the disappearance of the carbon monoxide occurred practically at the same time throughout this entire area. At the Nottingham fire, the carbon monoxide was eliminated at seal 4 on May 15, at seals 1, 2, and 3, on May 22. The analyses in both of these instances were succeeding analyses, so that although there is a difference of seven days, the elimination of the carbon monoxide may have occurred in one day.

This question, when is a fire out, is one we should know more about. From indications we believe that these fires were quickly extinguished after they were sealed; in other words, these areas could have been opened much sooner than they were; but the question is, how much sooner?

Has it been the experience in the anthracite mines that in a tightly sealed area, where there may be no fire, the oxygen content will disappear? That is the experience in the bituminous mines, as we have found repeatedly. The oxygen rapidly disappears, being either combined or absorbed by the carbonaceous material.

We have had no experience along that line. We have never made any analyses in closed areas free from fire, but my opinion is that the oxygen content will diminish; CH4 would naturally increase.

This paper deals with conditions in the Wyoming, or northern, anthracite field, where the veins are of moderate thickness and the pitch of the measures is light. Conditions in the southern anthracite field are markedly different. There the Mammoth vein attains a thickness of over 100 ft., under special conditions, and the average pitch of the measures is 70°. Also, a great deal of the workings are in gob areas, or areas previously mined and now being reworked. Most of our fires have occurred in such areas and in some cases the situation has been further aggravated by the fact that rolls or contortions of the measures have doubled the Mammoth vein on itself, forming what is known, in local parlance, as “capped anticlines.”

Under these conditions, sealing or extinguishment of fires by smothering is practical only to a limited extent. Sometimes sealing is used in conjunction with other methods, but the method finally evolved is to fight the fire from above by means of water. It must be understood that these are not fires that break out into a blaze or that have the normal features of a conflagration; they are smouldering or creeping fires that advance slowly through the gob with limited air supply, and burst into a blaze only at points where the air supply is ample. Such fires are often difficult to detect until they have spread over large areas. In recent years, we have men go through the workings each night, after the miners are out, in an endeavor to locate any fires that may be starting.

The cause of many of the fires is obscure. Often these fires are not discovered until years after the workings in the areas have been completed. The most probable cause is the burning of powder in a loose hole, which is a fairly common occurrence in gob workings. The mysterious nature of these fires, however, has led to various ingenious theories as to their origin. There is still some leaning toward the theory of spontaneous combustion. It is believed also that gas accumulates in large open spaces in old workings, and is ignited by sparks from falling rocks, especially those containing iron pyrites.

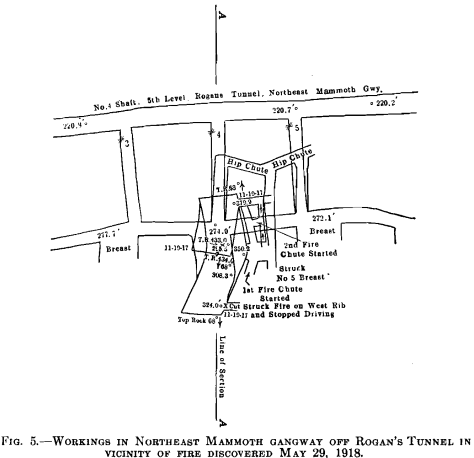

The accepted method of fighting these fires is by putting water in at the outcrop or from an upper level, or by driving chutes in one of the small underlying veins and cross-cutting back to the big vein above the fire by means of rock holes or small tunnels. This latter system is necessary in any case in order to explore the fire area thoroughly and to be sure that the fire is entirely out. To do this requires the driving of a considerable yardage of chutes, headings, and tunnels. To illustrate the methods pursued in fighting these fires, a brief description of three will be given.

The Coaldale fire started in December, 1914. Here the Mammoth vein is on a 45° pitch. The fire was fought by direct methods, then by driving into the fire area at various points from the underlying Skidmore vein. Tunnels and chutes, the latter both in coal and rock, were driven to isolate and fight the fire. After the area of the fire was definitely determined, the gangways, tunnels, and chutes were sealed. The holes and crevices, as well as the space back of the dams, were filled with culm until the area was effectively sealed and the fire smothered. In addition to the pumps and ventilation expenses in connection with this fire, 1500 ft. of chutes and 2000 ft. of headings or holes were driven around the fire, as well as a tunnel to fight the fire, at an expense of $125,000. Thirty men were employed on each shift driving chutes and headings, six men carrying timber and supplies to the miners, in addition to an assistant foreman or fireboss to patrol the area and look after the safety of the men. In this case, it was possible to smother the fire by means of the seals on the gangway level supplemented by the culm poured in on top of the fire area with the water, which thoroughly filled all crevices and other openings, completely shutting out the air and also extinguishing any fire with which it came into direct contact.

This method of pouring culm mixed with water into a fire area has enabled us in the past 6 years to cool off and practically extinguish the

entire area of the famous Summit Hill mine fire. In that area the fire is comparatively close to the surface and the vein is on a fight pitch, so that the culm and water can be introduced into the fire area by churn- drill bore holes with little difficulty.

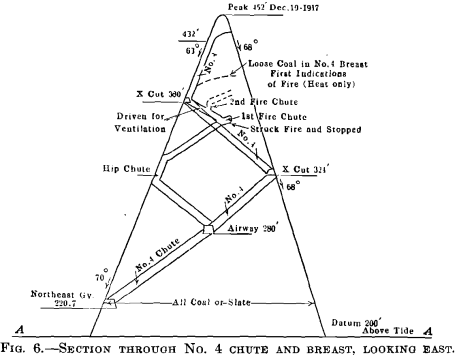

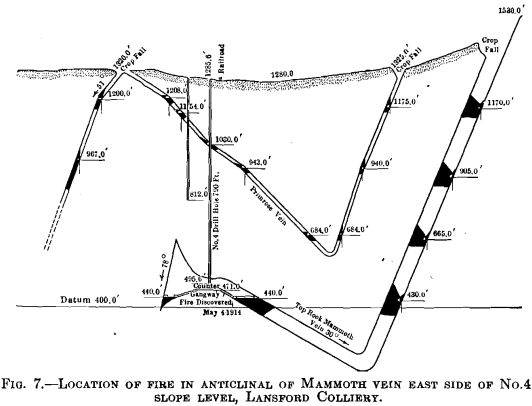

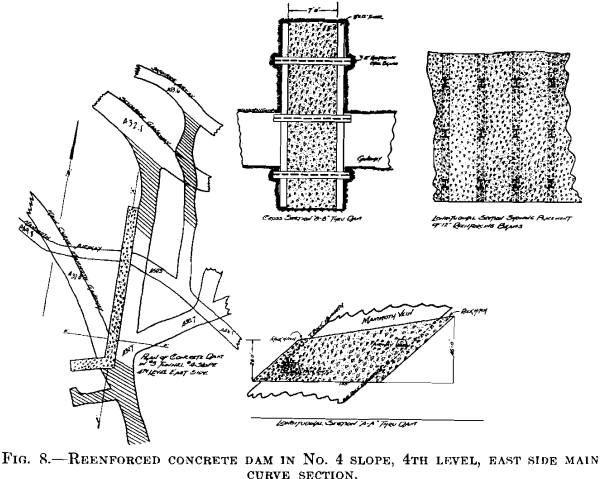

The Lansford fire, Figs. 5, 6, and 7, was discovered May 4, 1914, in the Mammoth vein, in the territory known as the Main Curve, No. 4 slope level. The vein in this area is in fault and caps. It is approximately 60 ft. thick and is on a 20° pitch. Rock holes and rock chutes were driven underneath the fire area, to locate it, and chutes were driven in the vein itself. This was one of our first experiences with this kind of fire and it was decided that conditions were favorable for sealing the area.

It was thought impossible to shut off all air from the fire, because previous workings had disturbed and shattered the pillars, but it was thought advisable to shut off the air as far as possible. At one end of the fire area a complete seal could be made by the ordinary brick dam. At the other end, there was a large opening on the gangway level and various smaller openings some distance above. It was therefore necessary to build walls of considerable length in sections approximately 8 ft. high, each section being built upon the previous one, as soon as excavation into the loose coal could be made, so as to provide room. The total length of this dam, including the wing on the south end is 143 ft. The bottom

was laid about 6 ft. below rail elevation in the gangway. The height of the dam at the south end was 26 ft.; at the north end, 46 ft. The width of the dam at all places was 7 ft. The entire dam was reinforced with rail and iron rods. Five-foot hitches were cut into top and bottom rocks and 8-ft. hitches in the roof on the north end; see Fig. 8.

Excavation for the dam was made in solid coal, with the exception of the top and bottom rock hitches. Timbering was kept up to the face of excavation by means of 12-in. steel beams 11 ft. long and 8 by 12-in. timber 7 ft. long. The 12-in. steel beams were used as collars and 8 by 12-in. timber as legs. These sets were placed on top of each other as excavation progressed until the required height was reached. The legs were set perpendicular so that plank could be nailed inside and used for forms for the concrete. The 12-in. steel beams made good reinforcement.

Concreting was done in three sections, the work being started as soon as excavation would permit. The south section of the dam (50 ft.) was completed first; then the middle section (50 ft.), and finally the north section (43 ft.). Work on the dam was started three days after the fire was discovered, May 7, 1914, and was completed March 8, 1915. After the dam was completed 35 tons of silt were pumped through a 6-in. pipe in the dam, to put a good backing of silt against the wall. The maximum height of water in the dam was 49 ft. Five 10-in. bore holes were started from the surface but only two reached the vein, the others being abandoned by the contractor because of the almost insurmountable difficulties

encountered in sinking through 700 ft. of caved ground. About 1800 tons of silt were run down into the fire, and also back of the dams. Two years later, after the area was reopened, no traces of active fire were found. The cost of fighting this fire was $180,000.

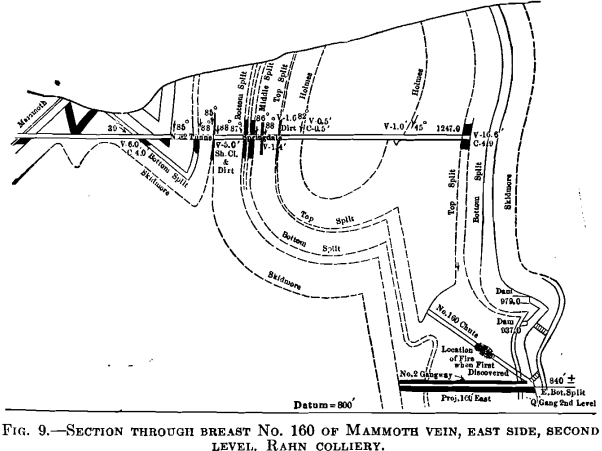

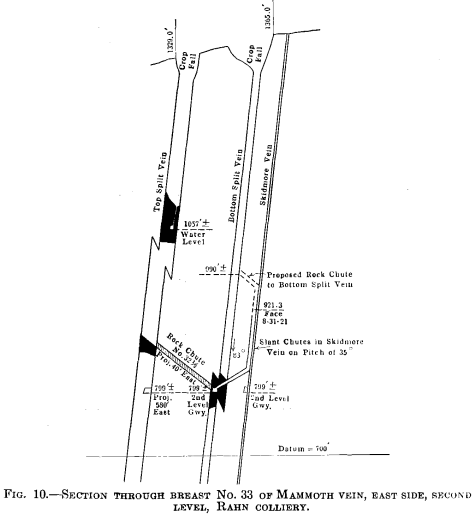

The third fire really consisted of several fires, probably of separate origins, though of this we are not sure. Their location is in the Mammoth vein at Rahn colliery along the Sharp Mountain invert. The fire area is in what is locally known as the east “Q” gangway. Here the vein stands practically vertical and the coal is soft and friable. The vein at breast No. 160, where the first fire was discovered above the gangway, on Feb. 6, 1918, is 200 ft. thick, because of a roll. About a year later, a hot area was noted on the outcrop 600 ft. above the gangway. To fight this fire effectively, it was necessary to drive several rock chutes from the Skidmore to the Mammoth vein before the best point to fight the fire was located. A fire tunnel was driven into the fire district from the Springdale workings, which are 400 ft. above those of the second level at Rahn, on which the east “Q” gangway is located. The crop coal was mined from this tunnel and water run down on to the fire from the Springdale workings. Water was also pumped to the outcrop and run down into the fire. The fire is in an area that has been partly robbed and extends down to the gangway. This condition prevents even the

partial isolation of the fire by sealing. In September, 1900, a cave occurred at breast No. 143 on the gangway, and we have not been able to get in to the fire area since on the gangway level, though water is still being run on to it from the upper workings.

On Aug. 10, 1921, fire was discovered about 30 ft. up chute No. 33. It had evidently reached a point where sufficient air was available to cause a blaze. This alone led to its discovery, as no work had been done anywhere near the area for about two years. When this fire was discovered, steps were taken to keep it off of the gangway by means of clay stoppings, behind which water was pumped. This fire is 6600 ft. west of the one discovered in 1918 and 2,000 ft. east of the shaft. No sign of fire has been noticed on the outcrop as yet. A 10-in. pipe line will be laid to the outcrop and water will be pumped into it. To locate the fire area definitely, and also to get above the fire, two rock chutes are being driven to the Skidmore vein from the Bottom Split gangway. One chute is 180 ft. east of the fire, and the other 140 ft. west of it. When the Skidmore vein is reached, two chutes will be driven from the rock chutes at an angle of 35°. These will intersect near breast No. 33 and up the breast about 150 ft. If a test chute from the junction point shows we are below the fire, we will then start a checker board system of chutes, until we get outside and above the fire. Water can be poured on it from the chutes. A pump has been placed in the ditch on the gangway, which

will furnish all the water necessary to use on the fire, in addition to the water pumped in on the outcrop. Owing to the robbed condition of the workings, the fire cannot be sealed.

Several days after the fire was discovered in chute No. 33, a hot spot was noticed along the outcrop at a point 2000 ft. east of chute No. 33 Whether this is another fire or whether it is connected with either or both of the other two, we do not know. The cost of the fire at breast No. 160 to date has been $84,000. This does not include all the cost of special tunnels, etc., at Springdale, as coal was won from part of the fire area.

We also have occasional minor fires starting on the gangway, or elsewhere, but these, so far, have been extinguished with comparative ease.

Naturally, mine fires in heavy pitching seams are dangerous to the fighters on account of gas and the difficulties encountered in getting material to the point where it is to be used. Ventilation of the chutes and headings from which the fire is fought is also one of the greater difficulties. It can readily be seen that in any computation of the cost of mining coal, the cost of fighting fires is an important item.

DOUGLAS BUNTING.—Were any chemical analyses made of the air in these closed areas?

HENRY H. OTTO, Lansford, Pa.—I do not think any analyses were made;I have only been at Lansford about a year and have not found any records of analyses in the reports in our files. Perhaps Mr. Ludlow can answer that.

EDWIN LUDLOW, New York, N. Y.—Such analyses were made.

DOUGLAS BUNTING.—Did they seal the return or the intake first?

HENRY H. OTTO.—I do not know. I have been there only a short time and these fires occurred about 1918.

E. M. CHANCE, Philadelphia, Pa.—Up to the outbreak of the war, when I was more or less actively interested in fighting mine fires, I had made many hundreds of analyses of mine air in fire areas.

The presence of carbon monoxide per se indicates that there is fire. Of course, carbon monoxide may be found in mine air, due to the use of explosives. But, on the other hand, we may have fire in a sealed area, and particularly such fires as Mr. Warriner has described in the Lehigh region, where the combustion is slow, has extended over a long period, and where the combustion temperatures are low. Under these conditions, little or no carbon monoxide will be found, therefore, its absence from a sealed area is no indication of the absence of fire. If, on the other hand, we have a fresh fire, such as Mr. Bunting has described in the Wilkes- Barre district, where the combustion is brisk and the temperatures are high, carbon monoxide will almost invariably be encountered. This is due to the fact that carbon monoxide is not readily formed at low temperature. The reaction of oxygen plus carbon produces almost wholly carbon dioxide, at temperatures of 1400° F. or less, whereas with high temperatures, such as those that we have in brisk, active combustion in new fires, with ample air supply, there is a rapid formation of considerable quantities of carbon monoxide when the fire area is sealed and the air supply is cut off.

I believe a far more accurate criterion of the presence of fire in a sealed area is an observation of large quantities of carbon dioxide. If a section of a mine is sealed, the oxygen content will disappear almost immediately, irrespective of the presence of fire; the amount of oxygen will drop to less than 1 per cent.; in fact, it will disappear entirely if the stoppings are tight. That is characteristic of almost any sealed area, where the stoppings are tight, whether there is fire present or not; but if a fire is present, accompanying this drop in oxygen there will be a rapid rise in carbon dioxide. This is not true where there is no fire. The carbon dioxide content, under those conditions will be low, possibly around 2 or 3 per cent. These figures I am quoting from memory, but they are only a general indication of the difference between the analysis of a total black air and one caused by the absorption of the oxygen in the enclosed air.

When a fire is sealed and the stoppings are on and the pillars are in good shape, so that the air supply is cut off, combustion will be almost immediately stopped; but that does not mean that the fire is out. We have two conditions in a fire—one is active combustion, the other is the presence of a mass of heated coal and heated rock. The combustion may be stopped immediately by the exclusion of fresh oxygen, but it takes time for the heat held by this mass of incandescent coal and rock to be dissipated by radiation; therefore, the gases characteristic of combustion may disappear. However, if the fire is of long standing, it will reappear, perhaps, when the workings are reopened. Therefore, it seems to me that the only safe guide in determining the extinction of a fire is to reopen the workings, remove whatever falls there may be, and examine them critically, because, although the combustion may have stopped, sufficient heat may be locked in the strata to renew combustion days or even months after ventilation has been re-established.

In sealing off a mine fire, extinguishing may be accomplished by creating a deficiency in oxygen. In the cases that Mr. Bunting has quoted, the workings were sealed off sufficiently tight for this aim to be realized, but this cannot always be done.

The fire area in No. 4 shaft was sealed off from the other part of the mine; the intake airway was sealed first. The other fires described were entirely in old gob workings. The fires may have started a week or five months before they were discovered. Our experience with fires in old workings is that an analysis of the return air from that section of the mine does not show conclusively whether fire is present or absent. In the case of the fire in the east “Q” gangway of No. 11, samples of the return air were taken a number of times but the analysis showed no trace of carbon monoxide, although the fire was burning.

The Summit Hill fire started in 1859 in the basin south of the Summit Hill anticlinal. That Summit Hill anticlinal dips to the west until it becomes a capped anticlinal, when it joins in the main basin, which is called the Lansford basin. The fire worked its way down toward this capped anticline. Various attempts were made to put out the fire. An open-cut was attempted, but the fire got around it. It was then decided to try to seal off the fire with drill holes and slush; this, however, was not successful for the fire worked its way around between the drill holes and to the west.

In 1908, a clay dam 12 ft. wide, with a cement core, was built across this basin and down to what was then water level in the mines (the coal was 250 ft. below the surface). The dam was carried down as an open-cut until there was over 50 ft. of surface, and was then carried in the vein itself by shafts 50 ft. apart, and the dam completed. This was considered entirely safe.

In 1912, not only was the fire burning up against this dam, but there was a good deal of steam to the west of it. After studying the outcrop of the fire and the type of the anticlinal, it was decided that it would be possible to strip off the surface, and recover the 50 ft. of coal lying under that anticlinal, which had been first mined a great many years before. This work was started as an open-cut. The temperatures, however, kept on increasing until at one time at 300 yd. west of this dam the temperature was over 550°. However, drill holes that were put down showed that the coal was perfectly cool. This temperature was in what might be called rock chimneys, or cracks in the rock over where the coal had been taken out and replaced by the dam, but the rock had been left above. The heat of the fire caused cracks and high temperatures in the openings in the overlying rocks, which had to be overcome in carrying on the stripping operations. We then started in to drive the fire back from the dam. Pumps were installed to take the breaker slush made at the Coaldale breaker, in the valley below, and were run during the 8 hr. that the breaker was in operation. It was found that this slush choked the drill hole, and it was necessary to follow that up with pumping clear water during the next 16 hr. By checkerboarding the fire area with drill holes, the slush was carried through the cracks in the rocks about 100 ft., making an air-tight seal that kept driving the fire back until it almost disappeared. The principal requirement was to keep the slush fine enough as it was put in, and to pump clear water during the night, in order to keep the slush clear and to fill the cracks in the rocks so far as possible. By following this plan, the fire was under control at the time I left Lansford.

Nothing has been said in this discussion regarding fighting fires by flooding a mine. I have a story to tell which may be an old one to many members of the Institute, but one that we can well bear in mind when we have occasion to consider the possibility of extinguishing a fire by shutting off its air supply.

About 12 or 15 yr. ago, I visited the old Midlothian mine in the Richmond coal field. Its recent history was that there had been a fire in the old workings for two or more years, and mining had been abandoned, although the water had been kept out. The fire was on a 300-ft. level, I think, and the bed of coal had a pitch or dip of about 30 or 35°—possibly a little steeper in places. Attempts to shovel out the fire and to fight it with water had failed. The air-ways, entries, and gangways were small and did not provide facilities for fighting the fire by these methods. So it was decided to flood the mine. The workings were not large; possibly a length of about 300 to 500 ft. was on fire; this was above the 300-ft. level; there was no fire below that level. As the mine was comparatively dry and made water slowly, it took possibly two months for the water to rise sufficiently to seal off the 300-ft. level. From that point on, the water rose rapidly in the shaft and quickly reached to within 18 or 20 ft. of the curb, so that the whole mine was thoroughly sealed by water. There were no outcrop holes, and the outcrop of the coal was below the natural water level of the country. The country is flat and there is a stream close by, running close to and above the place of the outcrop which is covered by soil and gravel thought to be about 15 or 20 ft. deep.

At the end of 18 months, it was thought the fire must certainly be out, so the water was pumped out, but the fire was still burning. Doubtless a large mass of rock and culm, probably including the formations above and below the coal bed, had become heated to a high temperature, and remained throughout the 18 months at a temperature at which active combustion recommenced as soon as air was admitted to the workings. The only solution seemed to be to flood the mine again, putting down a borehole to allow the air in the old workings to escape, so that the water could reach the seat of the fire.

Of the various ways of fighting mine fires, sealing is probably the one mostly used; this, at least, has been the experience of the Susquehanna Collieries Co. Our experience with the sealing of mine fires has shown that the methods of attack must be varied. In some cases we were able to seal off with stoppings; in others, we were only able to seal the bottom, or as it might be said, to shut off the drafts; in other cases, it was possible to do just the opposite, i.e., shut off the top, or chimney. This last method is now being used at one of our operations. The lower part is open, but because of inaccessability, on account of old workings, and also in order to keep another level working, a booster fan is kept going; this holds up the air in the so-called sealed section.

Analyses of the air from the upper stoppings show that the oxygen is nearly exhausted and that the carbon monoxide is reduced to a minimum, showing that the upper stoppings are tight and that the fire is consuming the oxygen. Just as soon as this low-oxygen air reaches the fire, the fire will die out. Of course, as to when this actually happens is only guesswork as we have not seen the fire nor do we know its exact location.

When the fire was first suspected, and to get the approximate location and determine what airways to shut off, we tested numerous places with a carbon monoxide indicator; this showed where the stoppings should be placed. After the stoppings were put in, the air in the upper airways began to accumulate carbon dioxide and depreciate in oxygen. As the air from the fire accumulated, we obtained it farther down the pitch. Every two weeks, we analyzed the air back of the stoppings, and twice a week the foreman tested the air with the carbon monoxide indicator; this shows the increase, decrease, or disappearance of the carbon monoxide at various levels.

The reason for sealing is to keep fresh air from the fire; therefore the stoppings must be tight, whether they are placed to shut off the draft or the chimney, or to surround the fire. Concrete stoppings are excellent. Wood stoppings are good, but will dry out and leak even if cemented. For this reason we coat the outside with a plastic roof material made of asbestos fiber and asphalt. This will dry and always be gummy enough to accept any slight movement of the wood and still keep the stopping tight. This material can be applied to a stopping made of concrete, brick, stone, or expanded metal with a cemented coating.

It has often been stated that filling the fire area with some inert gas, such as carbon dioxide, nitrogen, etc., would extinguish the fire. This is true, if the section is sealed tight; but as the area to be filled with gas is large this method would be costly. As the products of combustion are the worst enemy of the fire why not seal tight and allow the fire to put itself out? If the fire is large, the results will be obtained more quickly. If the fire is small and confined in a large sealed area, the time necessary to consume all the oxygen will be so great that it will pay to give the fire air so that it will increase in size in order that when the air is shut off the time required to consume the oxygen will be reduced considerably. This has been done several times to our knowledge.

A fire located in an old abandoned section, where the strata are broken through to other old veins or to the surface, is one of the most difficult to cope with. Under these conditions the best plan is to determine and seal the inlets and then try to put air depleted of oxygen, such as stack gases, into the main intake.

When sealing a mine fire, while the last few stoppings are being placed, mine gas may accumulate above the fire and explode, blowing out these stoppings. These explosions may occur at regular intervals or the intervals may differ in length. Quickly replacing a blown-out battery will lengthen the interval between explosions, but at one of our fires the batteries were so located that it was necessary, after quickly repairing them, to get so far away one could not tell just when the explosion occurred. It was then necessary to crawl back cautiously to investigate; if the battery was wrecked there was no way of telling how long before the explosion had occurred. To overcome this uncertainty and to know the exact time of the explosion, so that we could immediately return and rebuild the stopping, the inside foreman built a wooden frame on all sides of the opening outside of the wrecked stopping and fastened a small roll of canvas at the top of this frame. When the explosion occurred, the vibration unrolled the canvas, forming a canvas trap door, thus preventing a large amount of air from immediately rushing in to feed the next explosion. The falling of the curtain also closed an electrical connection causing a bell at the foot of the shaft to ring. After a few explosions the intervals became greater, until we were able to build the permanent battery.

We have two kinds of mine fires in Great Britain, one caused by the use of naked lights, and the other, which is much more prevalent and serious, caused by spontaneous combustion. The spontaneous combustion fires occur in both the open- light and the safety-lamp pits. We have no definite rules for the treating of mine fires—in each case the treatment depends on the conditions but generally sealing off is adopted. Until quite recently, we attempted to dig them out, but have decided that sealing off is the best method.

Fires caused by spontaneous combustion in the safety-lamp pits are the most serious and the most common. In the deep mines of South Yorkshire (which vary from 700 to 1100 yd. deep) there is a fire in some form or other all the time. We try to catch a fire at the first sign of heating before any flame or any red heat has developed. We have tried various ways of detecting when it begins to heat, such as taking samples of the return air and having them analyzed, etc., but we have returned to depending on the nose. The smell of gob stink, to those who know it, can be detected with the nose much more quickly than by any other method. As soon as gob stink is detected, the men from that district are withdrawn, and that area is thickly coated with stone dust. You must remember that these pits are hot, deep, dusty, and very gassy; they are all worked longwall. The first thing we do is to dust thoroughly all that area, right to the face, with stone dust; then build off the affected area. The building off is done by coating all the longwall buildings, called pack walls, with loose sand. If this is put on by hand and pushed into all the crevices, it makes a comparatively good air-tight stopping. At the same time all the roads into the particular area (which is generally about 100 yd. square) are built off. We put in a stopping of loose dirt first, then a building of sand, then a brick wall, then outside of everything we put in sand, piling sand all around until the air is wholly excluded. While building off, we restrict the air reaching that area; we do not cut it off wholly, we regulate it. The last thing which is done is to build the return side. The building off of the last stopping is generally done with breathing apparatus either self-contained or helmet type. Of course, we are provided with birds.

In dealing with spontaneous fires in non-gassy mines, we use much the same precautions but do not withdraw the men because there is little gas made, and most non-gassy mines are also damp. Sometimes, a fire occurs in the middle of a pillar, in which case we dig it out. In digging out fires, we invariably attack them on the intake side taking a plentiful supply of air and water with us. Brattice is taken up and the men work on the fresh side, the fumes going down the other side. If necessary, breathing apparatus is used.

As regards spontaneous fires that have been sealed, we have no data as to whether or not those fires are out. Areas in the east of Scotland that have been opened after 40 yr. have blazed again within a very short time. These are seams near the surface; so it has been argued that the fire draws air through cracks, from the surface, and that it is practically impossible to get them out. We are working places like that. When we reopen them, we open up only a part at a time and as we advance we fill in the waste with flushed material from the surface—flushed sand through pipes. The water is pumped back to the surface again and the small stone, sand, and other stuff, is left. That makes a very tight joint. Many fires occur in open-light pits from the carrying of open lamps in the cap. The method we are trying to adopt in these mines is the withdrawal of those lights and the substitution of some sort of electric lamp. In the case of a fire caused by a naked light, we almost invariably (unless it is impossible) attack it from the intake side with water and dig it out. If that fails, we seal it off by dirt or brick stoppings, always with sand on the outside.

A number of years ago, it was decided to fill in with slimes, and that work is being conducted on a very large scale. A large force of men is continuously at work, using a half dozen diamond drills and three cement guns filling the old stopes, from the bottom up. Many of the stopes have already been cooled off and valuable pillars recovered; but the particular points of interest are the combination of this filling through diamond- drill holes, forcing the slimes in under pressure, and the extensive use of the cement guns. Owing to the wide area of the affected zone, there is a movement of the ground and the rocks were all cracked, so that ordinary sealing and plastering was not effective. The cement gun proved an admirable means of filling in the cracks, and in some places where the ground was too broken, brattice cloth supported by chicken wire has been placed along the wall as a backing for the coating put on by the cement gun. The thin cement wall thus built up stands out from the rock wall and has a certain amount of flexibility. It is carried back a long distance from the stopping to prevent air leaking through broken ground. From observations made at different times during the last few years, I can say that this is a most admirably conducted plan and is well worth the attention of the colliery engineers, who have had so much trouble and difficulty in controlling fires in thick, pitching beds.