Mining companies around the world are looking at a new type of product to boost safety levels in their mines and reduce the risk of explosions. No, it’s not a new device: it’s vintage space technology.

Mining companies around the world are looking at a new type of product to boost safety levels in their mines and reduce the risk of explosions. No, it’s not a new device: it’s vintage space technology.

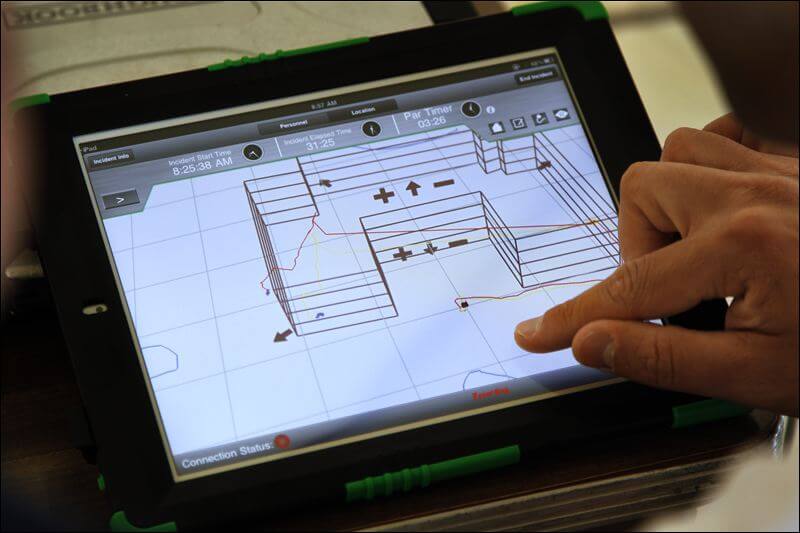

A new solution to create more resistant computer screens was inspired by the old materials used in space missions. The problem is that beneath the Earth’s surface, the glass in the screen breaks too easily and plastic screens are dangerous, since they accumulate a static charge that can generate a spark when touched. And we all know how sparks are dangerous inside a mine full of coal dust clouds.

That is why the engineers at the German mine-equipment manufacturer Marco Systemanalyse und Entwicklung GmbH started working with the European Space Agency to find a solution. Through the agency, the company got in touch with MAT PlasMATec GmbH, in Dresden, a firm that had developed coatings for space mission several years ago. The same coatings that could be used to protect plastic screens.

Werner Dupont, from the ESA’s MST Aerospace, says that:

We saw that the coatings developed by PlasMATec for spacecraft could provide an intelligent solution to Marco’s mine problem.

PlasMATec started developing the transparent coatings before 1989. At the time, a team of engineers tried applying indium—tin oxides to coat lenses and windows for spacecraft with good results. Similar coatings were later used on ESA’s SOHO satellite to control the temperatures.

Currently, these coatings are used in everything from liquid crystal displays to touch panels, conducting electricity in safe ways: in other words, the material can be applied to surfaces as a thin and transparent layer.

So, space experience developed the right solution for this current problem without us even knowing about it. PlasMATec’s experience helped the engineers at Marco to repurpose the transparent layer of indium and tin and apply it to mining equipment. This way, the conductive coating prevents electrostatic charge from building up on the screen, stopping sparks from happening and diminishing greatly the chance of underground explosions.

Via laboratoryequipment.com